Critical Path Analysis: Optimizing Production in Medical Manufacturing

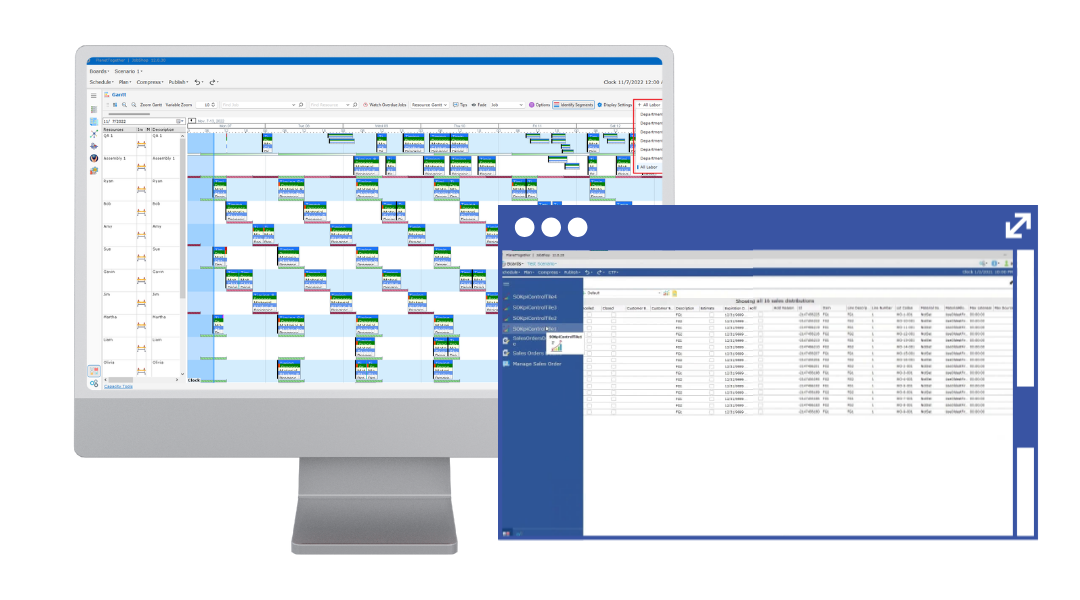

Every process, from procurement to production, must be streamlined to ensure timely delivery of life-saving products without compromising quality. In this digital age, the integration of advanced software solutions like PlanetTogether with ERP, SCM, and MES systems has revolutionized the way manufacturers operate.

One such indispensable tool in optimizing workflows is Critical Path Analysis (CPA). Let's look into how CPA empowers manufacturing IT in medical facilities to navigate complex production environments seamlessly.

Understanding Critical Path Analysis

At its core, Critical Path Analysis is a project management technique used to identify the longest sequence of dependent tasks and determine the shortest possible duration for completing a project. In the context of medical manufacturing, where every second counts, CPA provides invaluable insights into optimizing production schedules, resource allocation, and inventory management.

Integration with ERP, SCM, and MES Systems

The integration of CPA with leading ERP, SCM, and MES systems such as SAP, Oracle, Microsoft, Kinaxis, and Aveva brings unprecedented efficiency to medical manufacturing facilities. By syncing data across these platforms, manufacturers gain real-time visibility into every aspect of their operations, from raw material procurement to finished product distribution.

Let's explore how the integration between PlanetTogether and these systems enhances critical path analysis:

SAP Integration

-

- Seamless data exchange between PlanetTogether and SAP ERP enables manufacturers to synchronize production schedules with procurement and inventory management.

- Real-time updates on material availability and lead times allow for proactive decision-making, minimizing delays and optimizing resource utilization.

Oracle Integration

- Integration with Oracle SCM streamlines supply chain operations by aligning production schedules with demand forecasts and supplier commitments.

- Critical path analysis within Oracle MES ensures that production workflows are optimized to meet tight deadlines while maintaining compliance with regulatory standards.

Microsoft Integration

- Leveraging Microsoft Dynamics ERP, manufacturers can automate repetitive tasks and focus on strategic initiatives to drive business growth.

- Integration with PlanetTogether enables dynamic scheduling, allowing for rapid response to changing market demands and unforeseen disruptions.

Kinaxis Integration

- With Kinaxis RapidResponse, manufacturers can achieve end-to-end visibility across their supply chain, facilitating better decision-making and risk management.

- By incorporating critical path analysis into Kinaxis' supply chain planning capabilities, medical manufacturing facilities can identify bottlenecks and prioritize tasks to meet customer expectations.

Aveva Integration

- Integration with Aveva MES enhances production efficiency by optimizing workflows, tracking performance metrics, and ensuring regulatory compliance.

- Critical path analysis within Aveva's manufacturing execution system enables continuous improvement initiatives, driving operational excellence and cost savings.

Benefits of Critical Path Analysis in Medical Manufacturing

Implementing critical path analysis supported by robust integration between PlanetTogether and ERP, SCM, and MES systems offers several key benefits:

Enhanced Efficiency

-

- By identifying the critical path and optimizing production schedules, manufacturers can minimize idle time, reduce lead times, and maximize throughput.

Improved Resource Utilization

- Real-time visibility into resource availability and capacity constraints enables proactive resource allocation, preventing overutilization or underutilization of assets.

Better Decision-Making

- Data-driven insights provided by critical path analysis empower manufacturing IT to make informed decisions, prioritize tasks, and mitigate risks effectively.

Agile Response to Changes

- In today's dynamic market environment, the ability to quickly adapt to changes in demand, supply, or regulations is crucial. Critical path analysis enables agile decision-making and ensures timely response to disruptions.

In the highly competitive landscape of medical manufacturing, optimizing production processes is imperative to stay ahead of the curve. Critical Path Analysis, when integrated with advanced software solutions like PlanetTogether and ERP, SCM, and MES systems, empowers manufacturing IT to streamline workflows, maximize efficiency, and deliver high-quality products on time, every time.

By leveraging the insights provided by CPA, medical manufacturing facilities can achieve operational excellence, drive innovation, and ultimately, save lives.