In the past, manufacturers were unable to have a clear and concise picture of what areas to improve within production which ultimately meant that their facilities lacked efficiency. As time has progressed, visual production scheduling became a reality and has enabled manufacturers to have clear insights into their production processes and schedules.

Visual production scheduling has become a must for manufacturing operations around the globe. This method ensures that you have a visual complement to your production scheduling system that allows to:

- Reduce costs

- Improve efficiency

- Streamline workflows

- Adhere to the production plan

- Deliver on-time

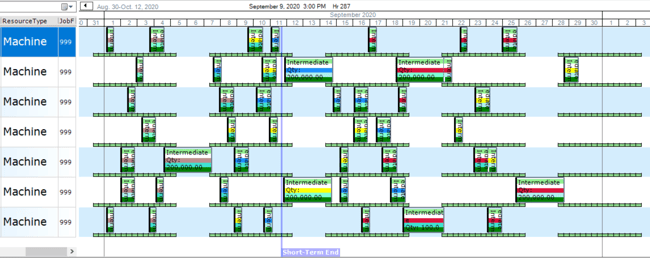

Advanced Production and Scheduling (APS) Softwares that use Gantt charts provide a great way for schedulers to visualize the production schedule. These softwares offer a concise visual representation of the production process and allow manufacturers to manipulate the schedule and make decisions that will create the most cost-efficient and optimized schedule.

The Benefits of Using Gantt Charts in Production Scheduling

Production plans are often illustrated with Gantt charts as they provide the solutions to coordinate activities scheduled on resources and offer visibility to identify potential issues before they arise. There are many benefits to using Gantt charts in production scheduling:

- Increased Visibility

- Communication Enhancement

- Efficiency Maximization

- Management Tools

- Superior Monitoring

- Impact Alerts

These benefits will be explained in more details in the following section.

1) Increased Visibility

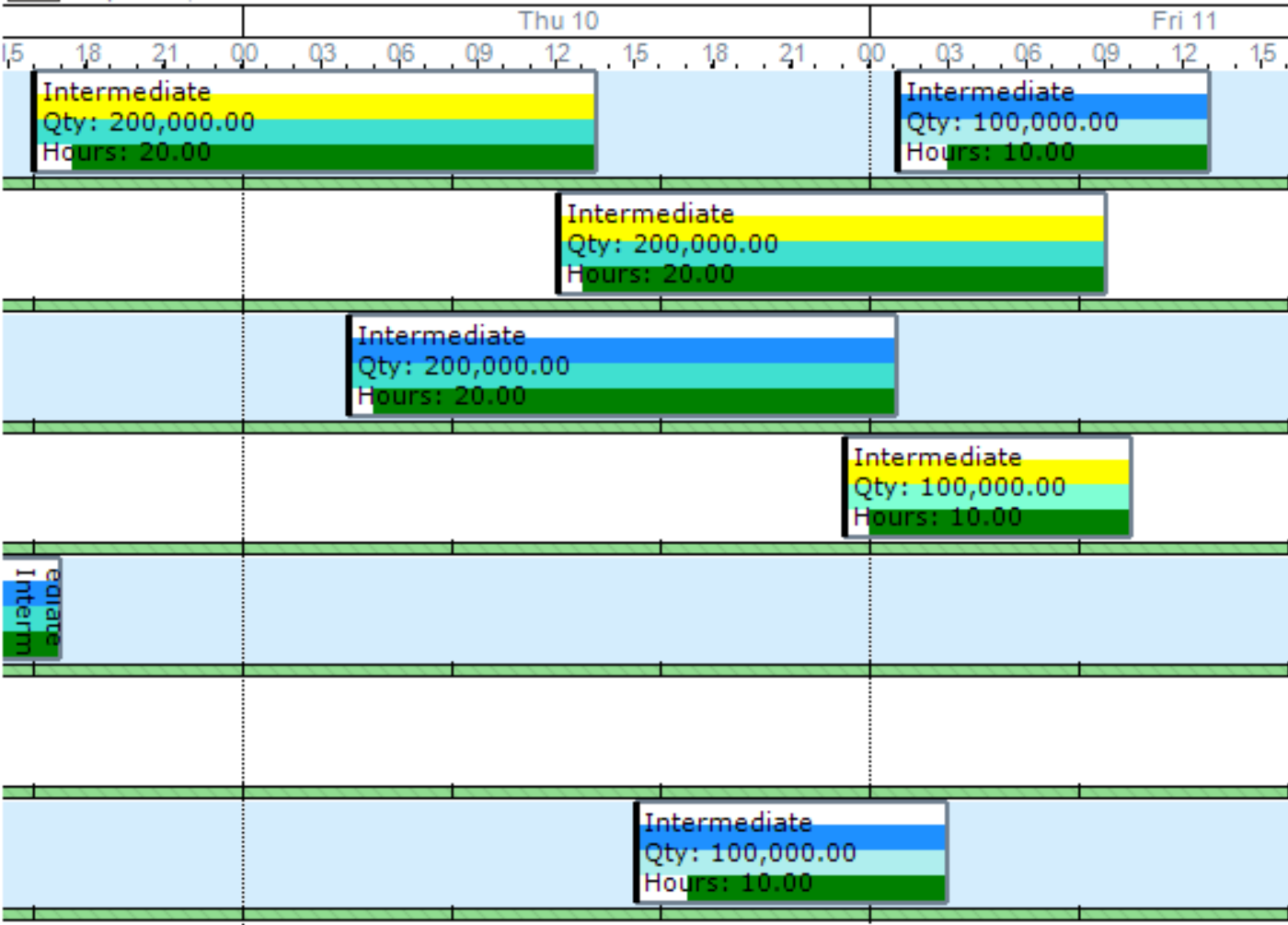

These charts illustrate a production schedule using activity blocks (that represent any operation) that are organized on horizontal lines (which represent resources). This allows you to see the production schedule on all resources at the same time.

The length of the activity block is proportional to the time required to perform the operation. This way, you can see which tasks take longer than others and may decide to split those operations between resources to meet your need dates.

2) Communication Enhancement

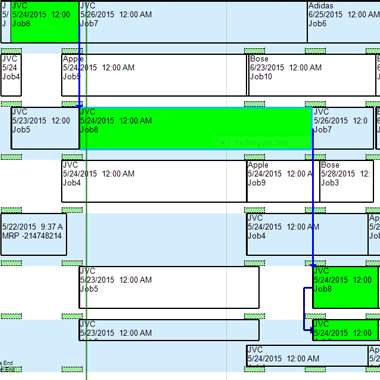

Visual production scheduling and Gantt charts are an excellent tool to communicate with shop floor employees and foster an environment of collaboration within the production facility. Activity links can offer increased visibility through the shop floor as they will illustrate the flow of WIP items from one resource to another. Shop floor employees can then easily see where their item is coming from and where it will go next.

3) Efficiency Maximization

Gantt charts allow for optimization within your production process and enable administrators to manage production and distribution runs to minimize lead times. Ultimately, this correlates with reaction times to manufacturing schedule improvements.

4) Management Tools

Gantt charts prevent responsibility confusion. Here, resources can represent machines or people and all tasks are clearly outlined and ensure that everyone understands what they are responsible for. This provides department managers with accountability tools that ensure acceptable employee performance.

5) Superior Monitoring

With a visual production schedule, management can easily view WIP inventories and subsequently arrange the manufacturing schedule to efficiently enhance production capability and inventory levels.

6) Impact Alerts

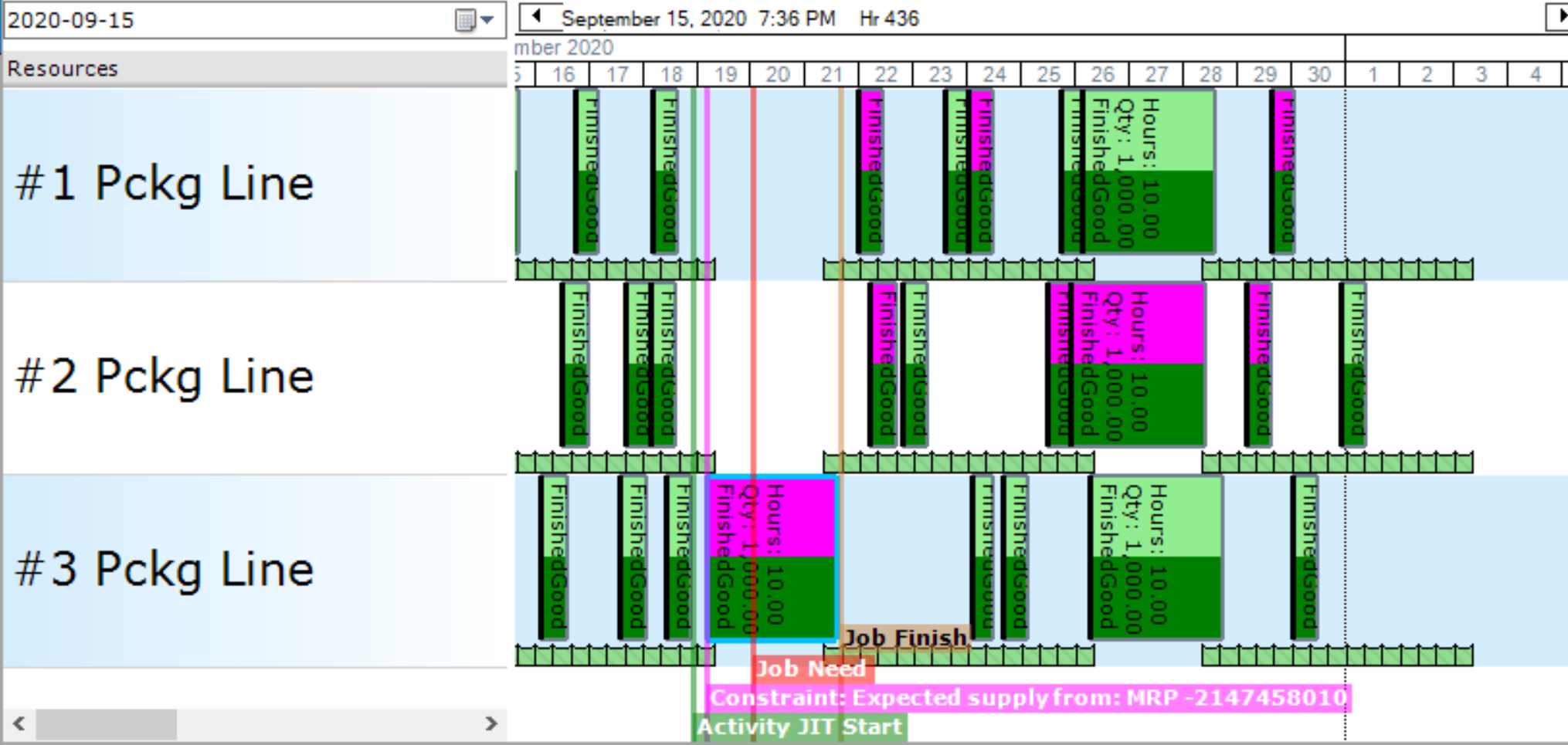

Gantt charts can help schedulers and planners quickly visualize the impact of the changes they make to the schedule beforehand so that they can fix any issues before they arise. PlanetTogether’s advanced Gantt labels allow planners and schedulers to identify whether you will have late jobs due to capacity constraints (highlighted in red) or due to material constraints (highlighted in pink).

PlanetTogether's Advanced Planning and Scheduling software (APS) has various features such as Gantt Charts that give you a visual representation of your production process. This software enables you to manipulate your production schedule until you have the most advantageous production schedule. Ultimately, this will lead to efficiency increase and waste reduction within your manufacturing facility and take your operation to the next level.

PlanetTogether is easier. Color-coordinated functionality makes the schedule simple to scan, and data is easily modified to fit our specific needs. I can look at my screen and know exactly when we’re running decaffeinated coffee. I know when jobs will be late, on time, case quantities. I see everything on one screen.

JAIME OZUNA, PRODUCTION SCHEDULER, ATLANTIC COFFEE

Drag & Drop functionality provides an additional level of dynamic planning and allows you to see the impact of any changes made in real-time. When an activity block is moved in the Gantt, the schedule will automatically accommodate this. No need to move each block one by one to accommodate the changes made. This unique feature allows for a much quicker and easier scheduling process.

Advanced Planning and Scheduling Software

Advanced Planning and Scheduling (APS) software have become a must for modern-day manufacturing operations as customer demand for increased product assortment, fast delivery, and downward cost pressures become prevalent. These systems help planners save time while providing greater agility in updating ever-changing priorities, production schedules, and inventory plans. APS Systems can be quickly integrated with an ERP/MRP software to fill the gaps where these systems lack planning and scheduling flexibility, accuracy, and efficiency

With PlanetTogether APS you can:

- Create optimized schedules that balance production efficiency and delivery performance

- Maximize throughput on bottleneck resources to increase revenue

- Synchronize supply with demand to reduce inventories

- Provide company-wide visibility to resource capacity

- Enable scenario data-driven decision making

The implementation of an Advanced Planning and Scheduling (APS) Software will take your manufacturing operations to the next level of production efficiency by taking advantage of the operational data you already possess in your ERP system. APS is a step in the right direction of efficiency and lean manufacturing production enhancement. Try out a free trial or demo!

Related Drag & Drop Video

APS Resources