In today’s manufacturing industry, many manufacturers believe that an ERP system alone is enough to plan and schedule production efficiently and increase profits. Unfortunately, an ERP system alone is not sufficient to improve your manufacturing operations. While ERP systems are able to manage functions such as technology, services, and HR, they lack strategic decision-making capabilities.

This is why Advanced Planning and Scheduling (APS) systems such as PlanetTogether APS were developed. APS systems are able to fill the gaps found in ERP systems in terms of planning and scheduling flexibility, accuracy, and efficiency.

With PlanetTogether APS, you have an advanced planning and scheduling software that can be directly integrated with your current ERP system and will allow you to improve your current ERP system capabilities.

Implementing Advanced Planning & Scheduling Software (APS)

An outdated belief might exist that implementation of an APS system is a time-consuming headache that is just too expensive. With PlanetTogether APS, this is untrue.

Advanced planning and scheduling (APS) software is offered as an extension of your ERP and can easily be integrated and implemented with various ERP systems quickly and in a cost-friendly manner.

When your ERP and APS systems operate together, production is enhanced dramatically. While these systems can operate independently from each other, the ERP system is not able to make the strategic decisions facilitated with an APS system. The integration of these two systems will be the best scenario for manufacturers looking to improve their production.

Advanced Planning & Scheduling - Features

Advanced planning and scheduling systems (APS) have many diverse features that will allow manufacturing facilities to improve their operations.

1. What-If Scenario Analysis

One of the most powerful features of PlanetTogether APS is its ‘What-If’ scenario functionality. This feature allows you to create a complete copy of your current production plan to allow you to test out various changes in a ‘sandbox’ environment. With this feature, you can identify which production schedule will generate the highest profits, or have the fewest late orders. It can also allow you to identify the effects of adding an additional machine or hiring an additional worker in terms of profits and efficiency.

2. Schedule Optimizations

PlanetTogether APS will automatically generate a production schedule that takes into consideration a multitude of scheduling constraints and preferences. Unlike other scheduling softwares, PlanetTogether will know which resources can perform which type of work and how long it takes to complete the operation. It can also automatically calculate setup time, based on various attributes or features of the product. Various optimization rules are available to allow schedulers to prioritize certain jobs. This allows you to create a schedule that is in line with your company goals, such as prioritizing jobs with a higher revenue or prioritizing jobs based on their need date.

3. Concurrent Planning and Scheduling

Another beneficial feature of PlanetTogether APS is that your production plans and schedules are generated at the same time. Too often, manufacturing facilities have production planning and scheduling processes that are disconnected. This can be problematic in the long run as you will create a production schedule based on the required date of the items without considering the available capacity of the resource, workers, or available materials used in production. With PlanetTogether APS, your resource capacity and inventory are planned at the same time as the production is generated. This means that your production schedule will be feasible and accurate, which will allow you to complete your orders on time.

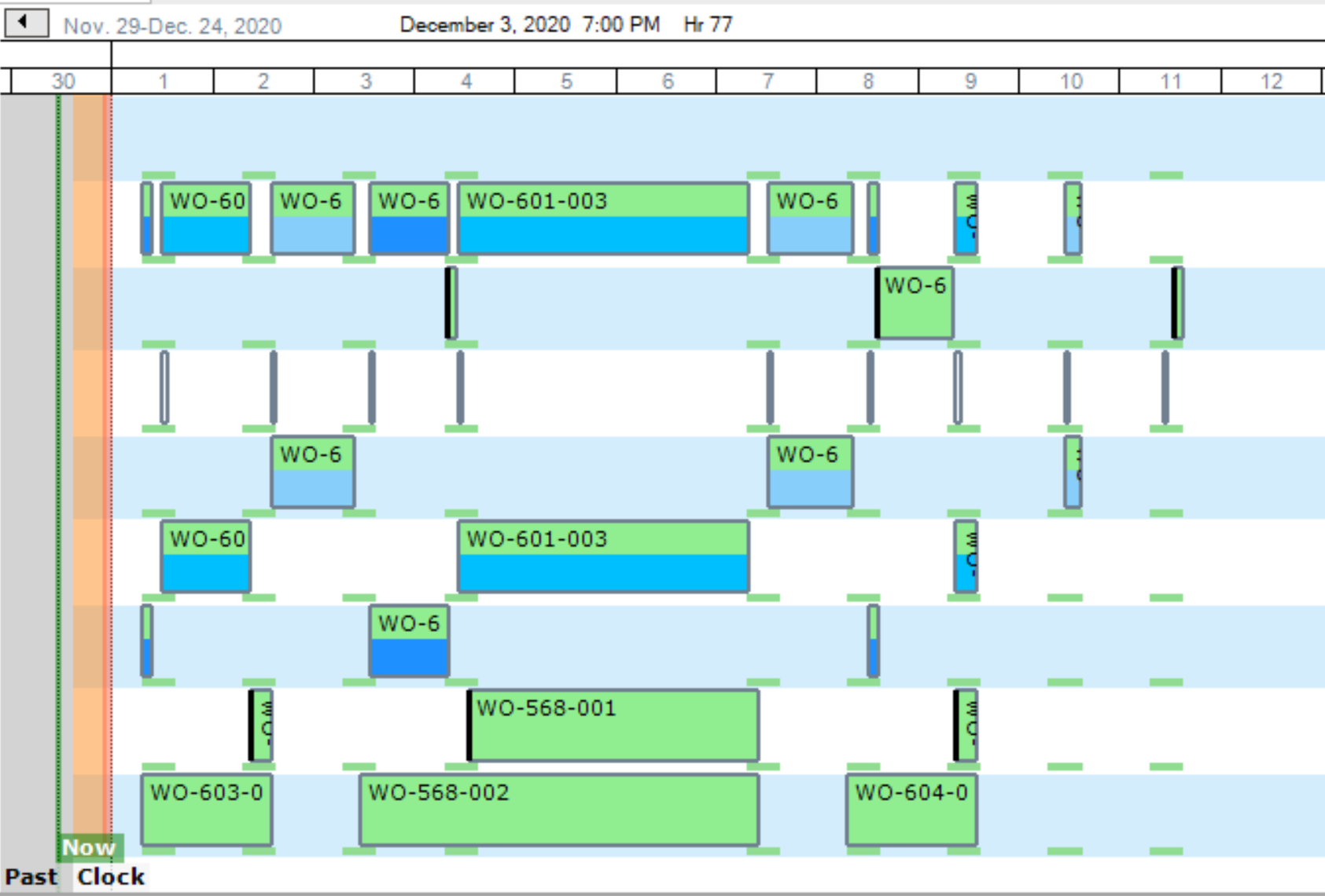

4. Drag-and-Drop Scheduling

Although PlanetTogether will generate the most optimal production schedule automatically, planners and schedulers can do manual adjustments in the Gantt view. In PlanetTogether, activities can be moved easily in the Gantt chart screen by clicking on the activity block to be moved and dragging it to the preferred position. The rest of the schedule will adjust to accommodate the move. For example, moving an activity to a later time will make all of its successor activities move out in time as well. Combining automated scheduling with manual adjustments gives users greater flexibility to generate schedules.

These are only some of the features available with PlanetTogether’s Advanced Planning and Scheduling systems. These powerful features will allow you to generate optimized production schedules and save your company time and money.

Advanced Planning & Scheduling (APS) for Large or Small Manufacturing Operations

Advanced Planning and Scheduling systems have been used by large production facilities ever since they were available. Large operations have always been in need of APS software to plan and schedule their production. Although some may think that Advanced Planning and Scheduling systems are only beneficial to large manufacturing operations, smaller companies can also benefit from the features that PlanetTogether APS has to offer.

The implementation of an APS system can allow your operation to adequately compete against larger manufacturing operations through schedule optimization, market analysis, order forecasting, and increased efficiency. These benefits will allow you to separate yourself from other small manufacturing competitors and optimize your production facility quickly and efficiently.

I can just say that every process, from order entry to warehouse planning, scheduling, materials planning, and so on, have ALL become more responsive and able to plan better with PlanetTogether APS.

CHUCK DIPIETRO, DIRECTOR OF PROCUREMENT & PLANNING, BEMA INCORPORATED

PlanetTogether APS is also beneficial for manufacturing facilities that are looking to expand their operations. The various features of PlanetTogether will allow you to see the effects of different scenarios to help you decide which area you should focus on during the expansion. Overall, you will be able to know what your investment will do for your business and your customers—before you make the investment.

PlanetTogether’s Advanced Planning & Scheduling (APS) Software

Advanced Planning and Scheduling Softwares have become a must for modern-day manufacturing operations as customer demand for increased product assortment, fast delivery, and downward cost pressures become prevalent. These systems help planners save time while providing greater agility in updating ever-changing priorities, production schedules, and inventory plans. APS Systems can be quickly integrated with an ERP/MRP software to fill the gaps where these systems lack planning and scheduling flexibility, accuracy, and efficiency.

With PlanetTogether APS, you can:

- Create optimized schedules that balance production efficiency and delivery performance

- Maximize throughput on bottleneck resources to increase revenue

- Synchronize supply with demand to reduce inventories

- Provide company-wide visibility to resource capacity

- Enable scenario data-driven decision making

The implementation of an Advanced Planning and Scheduling (APS) Software will take your manufacturing operations to the next level of production efficiency by taking advantage of the operational data you already possess in your ERP system. Try a free trial or demo!

Related PlanetTogether Video

APS Resources