Leading Work Management Solution

- to Streamline Workflow

- to Gain Visibility

- to Simplify Planning

- to Enable Collaboration

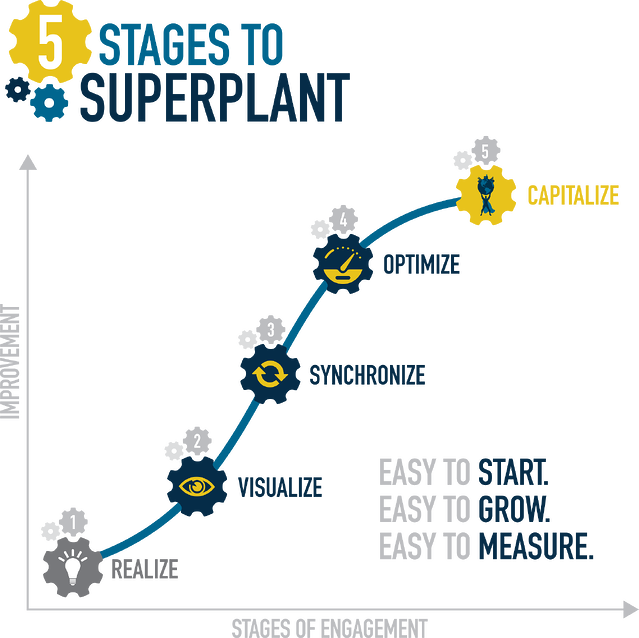

SuperPlant is a cohesive, nimble and value-creating system of plants optimized by operations planning and scheduling solutions. Unlike any other solution in the market, PlanetTogether’s software and thoughtware are designed to maximize its clients’ KPIs in complex, multi-plant production environments…leading to SuperPlant performance.

Unlock strategies to boost efficiency, streamline production, and overcome operational challenges with our comprehensive eBook. guide has you covered.

Get our free ebook on how you can level up your B2B SaaS content marketing

Capacity planning for JIT, agile and lean manufacturing is vital to achieving SuperPlant status. Production control, prioritization, visualization, as well as "what-if" scenarios and reporting can be the tools in your arsenal to take efficiency to that highest level.

High Return on Assets

Boost Production Output

Cut Operating Expenses

Empower Teams for Success

Cross-plant Visibility

“What-if” Scenarios

Optimize Plant Loading

Capacity & Inventory

Visibility

Create Schedules Faster

Overcome Bottlenecks

Keep Delivery Promises

Shorter Lead-times

Stay Informed

With PlanetTogether APS, SuperPlant is not as far of a leap as you might think. Take a look at how others have used optimization and proper capacity planning to increase efficiency, capacity and the bottom line. ROI can be as little as six months away income instances.

Optimizing Resources, Maximizing Efficiency.

Inventory Management for Greater Control and Accuracy.

Enhancing Planning for Improved Accuracy and Operational Efficiency.

.png?width=2560&height=1063&name=Planning%20(3).png)

Visualizing Schedules for Clearer, More Efficient Project Management.