What Does the Future Hold for Chemical Manufacturing in 2025?

The chemical industry has always been a cornerstone of modern society. From creating the medicines that keep us healthy to the materials that make our homes and cities, chemical manufacturers are the unsung heroes behind many of the things we rely on. But as we move further into 2025, the industry is facing a rapid transformation, driven by new technologies, sustainability pressures, and shifts in global demand.

In 2024, the global chemicals market surpassed $5 trillion, according to the American Chemistry Council, and it's expected to continue growing at a steady pace. However, as demand rises, chemical manufacturers must tackle complex challenges—how to improve efficiency, meet sustainability goals, and cope with an increasingly unpredictable global supply chain. The future of chemical manufacturing looks set to be vastly different from the past, and it’s not something you can afford to ignore.

So, what are the key directions for chemical manufacturing in the near future?

1. The Rise of Automation and AI in Manufacturing

Automation is no longer a future vision—it's already happening. And with the rise of artificial intelligence (AI), chemical manufacturers are on the cusp of a new era of efficiency. AI can help improve product quality, streamline production schedules, and even predict equipment failures before they occur. A McKinsey study from late 2024 revealed that AI could add up to $1.5 trillion to the global chemical industry by 2035, thanks to reductions in operating costs and improved innovation cycles.

2. Sustainability at the Heart of Manufacturing

Sustainability isn't just a trend anymore; it’s a central focus for chemical manufacturers. With increasing pressure from both regulators and consumers for eco-friendly products, sustainability is top of mind. In fact, according to the World Economic Forum, the chemical industry accounts for about 20% of global industrial energy use. By 2025, many companies are expected to cut their carbon emissions by at least 30%, with an even larger shift toward bio-based and recyclable materials. The growing adoption of green chemistry and circular economy practices is helping manufacturers lower their carbon footprints while meeting the demand for sustainable products.

3. Smart Manufacturing and the Internet of Things (IoT)

The future of chemical manufacturing lies in connected factories, where machines, sensors, and data analytics work together to improve decision-making. IoT is making this a reality, allowing manufacturers to gather real-time data on equipment performance, inventory levels, and production efficiency. By 2025, the global market for IoT in the chemical industry is expected to exceed $9 billion, according to Statista, unlocking new levels of transparency and predictive capabilities in manufacturing operations.

4. Development of Advanced Materials

The drive for new and innovative materials will continue to shape the future of the chemical industry. From biodegradable plastics to high-performance materials for industries like automotive and electronics, the focus is on creating materials that are both stronger and more sustainable. As part of their commitment to innovation, companies like BASF are investing in new bio-based materials, which are expected to be a game-changer in meeting the growing demand for eco-friendly products.

5. Resilient and Transparent Supply Chains

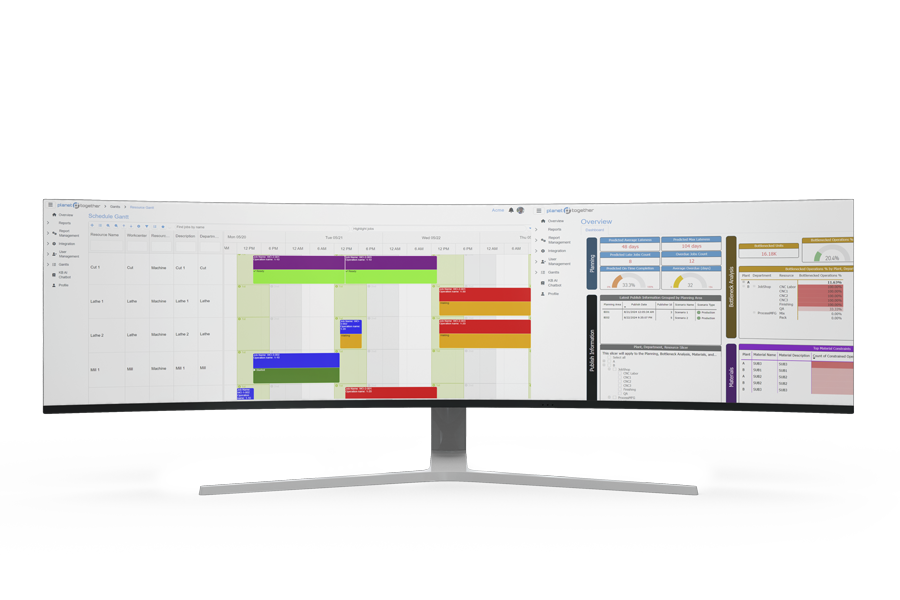

Recent disruptions to the global supply chain have shown just how vulnerable the chemical industry can be to external shocks. Manufacturers are now looking for ways to make their supply chains more resilient. By incorporating advanced planning and scheduling (APS) systems, companies can gain real-time insights into inventory management, improve forecasting, and enhance overall supply chain visibility. The global APS market is expected to reach $7.3 billion by 2027, driven by manufacturers seeking more efficient and adaptable supply chain solutions.

Redefining the Future of Chemical Manufacturing

As we look to the future, the chemical industry is at a pivotal moment. The need for innovation, sustainability, and resilience is driving rapid changes in manufacturing processes. Automation, AI, sustainability, and smart technologies like IoT will redefine how companies operate. With the chemical market continuing to grow, companies that stay ahead of these changes will not only survive—they will thrive.

For chemical manufacturers, adopting advanced planning and scheduling (APS) systems will be key in navigating the future. These systems enable real-time production optimization, better resource management, and a deeper understanding of supply chain dynamics, helping manufacturers remain competitive in an increasingly complex world.

👉Click here to download your free ebook: How Can We Build Resilient Chemical Supply Chains?

The future of chemical manufacturing is filled with immense potential. By embracing new technologies, sustainability practices, and smarter operations, manufacturers can unlock new opportunities and drive growth. Now is the time to take action and prepare for what's to come.

Are you ready to stay ahead of the curve? Request a demo of our APS solution today and discover how you can optimize your operations for the future.