What Does the Future of Mobility Sector Manufacturing Look Like?

The mobility sector has undergone a rapid transformation in recent years. The rise of electric vehicles (EVs), autonomous driving technologies, and smart transportation systems has reshaped not just how we travel, but also how manufacturers approach production. With the increasing focus on sustainability, technological integration, and shifting consumer demands, the industry is preparing for an even more dramatic evolution in the coming decades. But what will manufacturing look like in the future? Let’s dive into the key trends shaping the future of mobility sector manufacturing and how these innovations will redefine production lines.

The Current State of Mobility Manufacturing

To understand where mobility manufacturing is heading, we first need to take a look at its current landscape. The global automotive industry, one of the largest sectors in manufacturing, is currently valued at around $4 trillion. But within this enormous market, the shift towards electric mobility is gaining momentum. In 2023, EV sales accounted for approximately 14% of global car sales, with projections suggesting that this figure could rise to 30% by 2030. With this seismic shift, manufacturers are rethinking their entire approach to production.

Electric vehicle production is more than just a matter of building a new kind of car; it involves designing more efficient supply chains, integrating advanced technology, and ensuring that factories are equipped to handle the complexity of EV production. In fact, the Global Manufacturing and Supply Chain Survey 2023 found that 72% of manufacturers in the automotive sector are adopting advanced manufacturing technologies like robotics, artificial intelligence (AI), and additive manufacturing (3D printing) to streamline their operations.

But it's not just electric vehicles that are changing the game. Autonomous vehicles (AVs) and smart infrastructure are also pushing the limits of manufacturing. AVs are expected to contribute $173 billion to the global economy by 2030, with manufacturers needing to adapt to new requirements for sensors, AI-driven systems, and communication technologies that enable safe and efficient autonomous driving. These emerging trends are prompting manufacturers to consider how they can evolve their processes to meet the future demands of mobility.

Key Trends in Mobility Sector Manufacturing

1. Sustainability and Green Manufacturing

As the world shifts toward greener transportation, mobility manufacturers are under pressure to reduce their environmental footprint. The push for zero-emission vehicles is driving the need for sustainable manufacturing practices. For example, companies like Tesla and Rivian are investing heavily in making their production lines more energy-efficient and implementing sustainable materials in their vehicles. As consumer demand for eco-friendly products rises, the market is expected to see increased efforts to reduce carbon emissions, energy usage, and waste.

2. Automation and Robotics

Automation is set to be one of the biggest disruptors in mobility manufacturing. Robotics and automation technologies are not just improving assembly line efficiency but are also enabling manufacturers to produce vehicles faster and with fewer errors. Automated systems are also aiding in quality control, precision, and the assembly of more complex components, such as batteries and autonomous driving systems.

A report by McKinsey predicts that by 2030, the use of automation in the mobility sector could increase productivity by up to 30%, enabling manufacturers to cope with increasing demand while maintaining cost-effectiveness.

3. Additive Manufacturing (3D Printing)

3D printing is making its mark on the mobility sector. It allows manufacturers to quickly prototype new designs, reduce waste, and create lightweight, complex parts that traditional manufacturing methods can’t replicate. Ford, for example, has used 3D printing to manufacture parts for their electric vehicles, which can reduce lead times and lower production costs. The ability to rapidly produce small batches of custom parts is also revolutionizing the after-market service industry.

4. Digital Twins and AI Integration

Digital twins—virtual replicas of physical systems—are being increasingly adopted in the mobility manufacturing space. These models help manufacturers simulate and test different manufacturing scenarios before they even begin production. By integrating AI into this process, manufacturers can optimize operations, forecast potential bottlenecks, and improve product quality. According to Deloitte, the adoption of AI in manufacturing is expected to increase efficiency by up to 25% in the next five years.

5. Smart Manufacturing and IoT

The integration of the Internet of Things (IoT) into manufacturing processes is paving the way for “smart factories.” In the mobility sector, this involves equipping machines and assembly lines with sensors and connectivity to monitor performance in real time. These smart factories use big data and cloud computing to optimize production processes and reduce downtime. In fact, the smart manufacturing market is projected to grow to $480 billion by 2025, with mobility manufacturers being key adopters.

Overcoming Obstacles: The Roadblocks to Future Success

Despite the exciting prospects, mobility sector manufacturing faces several challenges. Supply chain disruptions, skilled labor shortages, and the need for significant capital investment in new technologies are just a few obstacles manufacturers must navigate. The shift to electric and autonomous vehicles, for instance, requires retooling production lines to accommodate new battery types and vehicle structures. This requires not just technology but strategic planning and collaboration across industries.

Another major challenge is the need for a flexible and scalable production system that can keep up with rapidly changing consumer preferences and technological advancements. Manufacturers will need to implement agile strategies that allow them to quickly pivot their production lines and processes to accommodate the demand for new vehicle types, technology integrations, and sustainability goals.

How Can Manufacturers Embrace the Future of Mobility Manufacturing?

Looking ahead, the future of mobility manufacturing is looking pretty exciting. It's going to be more dynamic, tech-driven, and sustainable than ever before. With electric vehicles, autonomous systems, and smart infrastructure on the rise, manufacturers are really rethinking how they do things. Those who can embrace these new technologies and make them a part of their everyday processes are the ones who will lead the way into this new era.

At the same time, mobility manufacturers will need to remain agile to navigate the challenges of a rapidly changing market. Investing in automation, digital technologies, and sustainable practices is no longer just an option—it’s a necessity. For manufacturers who are ready to take the leap into the future of mobility manufacturing, the opportunity for growth, innovation, and efficiency is immense.

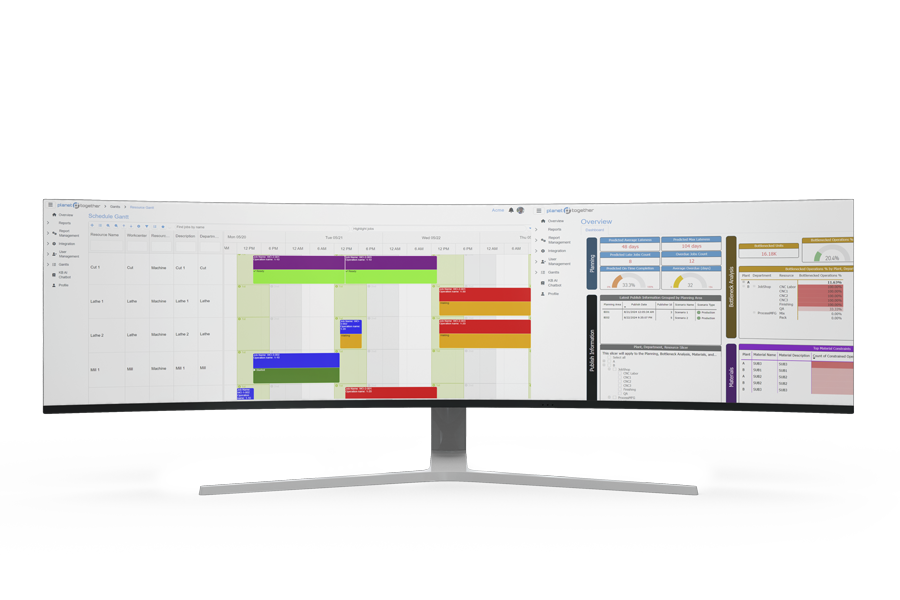

At PlanetTogether, we understand the unique challenges and opportunities in the mobility sector. Our advanced planning and scheduling solutions help manufacturers optimize their production lines, improve efficiency, and stay ahead of the curve in this rapidly evolving industry.

Ready to transform your mobility manufacturing operations? Request a demo today and see how PlanetTogether APS can help you stay ahead of the competition.