Knapheide Truck Equipment Case Study

Five thousand trucks roll off the line at Knapheide Flint each year. Service truck bodies, dump bodies, snow plows, platforms, premium dry freight vans, lift gates, van interiors, and crane bodies. Up to twenty jobs run concurrently at any time in the production scheduling department.

Five thousand trucks roll off the line at Knapheide Flint each year. Service truck bodies, dump bodies, snow plows, platforms, premium dry freight vans, lift gates, van interiors, and crane bodies. Up to twenty jobs run concurrently at any time in the production scheduling department.

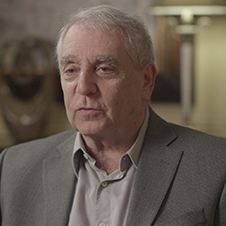

When Dick Marx joined Knapheide Flint as materials manager, he was surprised to find that the company still relied on an enormous magnetic board to schedule jobs. In his mind, manufacturers wouldn’t expect their engineers to design with a pencil or ruler; why make planners/schedulers use a white board or spreadsheets?