The only way you can get through big projects is to take it a day at a time. When a rather substantially large project is coming your way, you may be concerned as to how you are going to begin or prioritize all of the tasks involved. Who is going to complete the tasks? How much should a budget be for these tasks? How many days of slack should be involved? All of these are adequate questions to ask when you are about to begin a big project and are an operations or project manager.

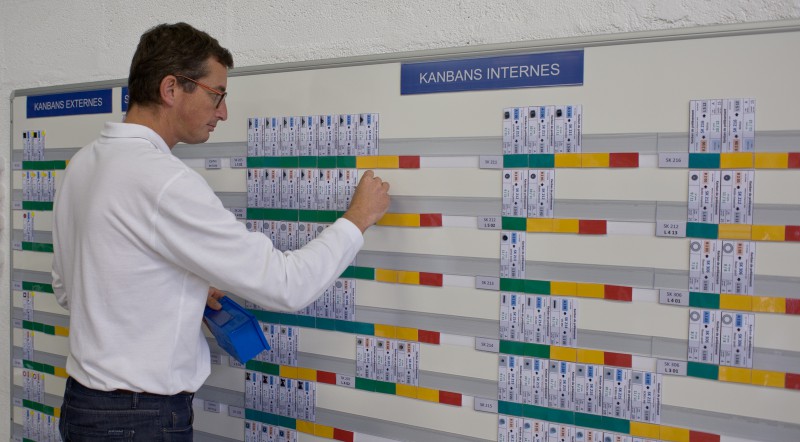

There is a simple solution that can aid with this concept: Kanban. Kanban aids in visualization and breaking down tasks within an operation into something more manageable. Utilizing Kanban aids in helping you stay focused, making sure you are doing the correct thing, and ensuring that you complete the project in the amount of time requested/needed. Kanban planning and methodology is being implemented into manufacturing operations around the globe and can easily boost efficiency and planning within the operation.

Why is Kanban Better Than a To-Do List?

There is some debate over why you should utilize Kanban over a to-do list or to-do list application. While a to-do list is great for much smaller tasks, it becomes incredibly unmanageable underneath a rather large project. With Kanban planning, especially within a software that utilizes lean methodology as well, it can aid various departments through a common understanding of what needs to be done and when. As a team, it allows everyone to gather around a board and talk through which tasks need to be done, in what order, and then by whom. You can use the same Kanban board to plan and manage your work, ultimately keeping everyone focused and in sync as the project progresses.

You may also be curious as to how it can benefit small projects. Kanban sounds adequate for large projects, so why would anyone with smaller tasks utilize it? Kanban is an adequate source for even small projects. Smaller projects still contain details, tasks, and minutes that are able to fall through the cracks. Kanban boards enable you to keep all details of the project into one plan and ultimately complete the project in the timeframe required. Regardless of whether or not your project is large or small - Kanban is the way to go.

How Can I Use Kanban Planning to Be More Productive?

Kanban completely eliminates that necessity to switch back and forth between “planning” and “doing”. This process takes a substantial portion of our day and can be cognitively exhausting and make the operation overall less effective. Without Kanban, there is a substantial amount of mental energy of just keeping track of everything that needs to be done.

This is why Kanban is a necessity for these operations, because the methodology allows us to keep record and store the ideas that are had while within the planning process - ultimately helping us to make sure that they actually do happen. Using Kanban to plan and manage your work will not only make you more productive, but it will also improve the quality of work within the operation. Therefore, utilize Kanban planning within your operation and reap the benefits associated with the methodology.

A software that can easily aid with implementing of Kanban planning and methodology is PlanetTogether’s Advanced Planning and Scheduling Software. PlanetTogether’s APS software is a must have for manufacturers that are seeking to improve efficiency within a manufacturing operation while cutting costs and increasing profitability. Advanced Planning and Scheduling Software is essential for manufacturing operations around the globe in order to maintain a competitive edge and keep up with industry technology.

Advanced Planning and Scheduling Software

Advanced Planning and Scheduling (APS) software has become a must for modern-day manufacturing operations due to customer demand for increased product mix and fast delivery combined with downward cost pressures. APS can be quickly integrated with a ERP/MRP software to fill gaps where these system lack planning and scheduling flexibility and accuracy. Advanced Planning and Scheduling (APS) helps planners save time while providing greater agility in updating ever-changing priorities, production schedules, and inventory plans.

- Create optimized schedules balancing production efficiency and delivery performance

- Maximize output on bottleneck resources to increase revenue

- Synchronize supply with demand to reduce inventories

- Provide company-wide visibility to capacity

- Enable scenario data-driven decision making

Implementation of Advanced Planning and Scheduling (APS) software will take your manufacturing operations to the next level of production efficiency, taking advantage of the operational data you already have in your ERP.

Related What If Video

APS Resources

Topics: Kanban

LEAVE A COMMENT