Value-Based Procurement in Medical Manufacturing

In the highly regulated and innovation-driven realm of medical manufacturing, purchasing managers play a pivotal role in ensuring the seamless flow of materials and resources while keeping a keen eye on compliance, cost efficiency, and supply chain agility. Yet, in an era where cost reduction alone is no longer sufficient, value-based procurement has emerged as a transformative strategy to achieve long-term business goals while delivering exceptional products to the market.

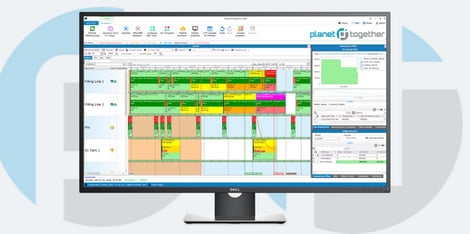

When integrated with advanced tools like PlanetTogether APS (Advanced Planning and Scheduling) and ERP systems such as SAP, Oracle, Microsoft Dynamics, Kinaxis, or Aveva, value-based procurement becomes a cornerstone for optimizing operations.

This blog explores the principles of value-based procurement, its importance for medical manufacturing, and how integrating advanced technologies can unlock unprecedented benefits.

What is Value-Based Procurement?

Value-based procurement shifts the focus from merely securing the lowest price to achieving the best overall value for the organization. It considers factors such as:

Supplier performance and reliability.

Quality and compliance of materials.

Lifecycle costs, including maintenance, support, and sustainability.

The ability to foster innovation and collaborative relationships.

This approach aligns purchasing decisions with the broader goals of the organization, ensuring that every dollar spent contributes to quality improvement, operational efficiency, and regulatory compliance.

Why Value-Based Procurement Matters in Medical Manufacturing

Regulatory Compliance and Quality Assurance

Medical manufacturers face stringent regulatory requirements. Poor-quality materials can lead to compliance failures, product recalls, and reputational damage. Value-based procurement ensures that suppliers meet or exceed industry standards, mitigating risks across the supply chain.

Cost-Effective Innovation

By prioritizing partnerships with innovative suppliers, purchasing managers can access cutting-edge materials and technologies that enhance product performance while keeping costs under control.

Sustainability and ESG Goals

Environmental, Social, and Governance (ESG) considerations are becoming a critical aspect of business operations. Value-based procurement enables purchasing managers to source materials that align with sustainability goals, such as reduced waste or lower carbon footprints.

Resilient Supply Chains

A value-based approach helps identify reliable suppliers and diversify the supply base, reducing dependence on single sources and improving resilience against disruptions.

Challenges in Implementing Value-Based Procurement

Complex Decision-Making

Weighing factors like quality, compliance, cost, and sustainability requires robust data analysis and strategic thinking.

Supplier Collaboration

Building strong relationships with suppliers demands time and effort, particularly in sectors like medical manufacturing, where precision and trust are critical.

Integration with Existing Systems

Many organizations rely on legacy systems that may not easily integrate with new procurement strategies.

Balancing Cost and Value

While value-based procurement aims to prioritize value, it’s often challenging to justify higher upfront costs to stakeholders focused on immediate cost savings.

![]()

Role of Technology in Enabling Value-Based Procurement

Advanced Planning and Scheduling with PlanetTogether

PlanetTogether’s APS software is a game-changer for aligning procurement activities with production needs. By integrating with ERP systems like SAP, Oracle, Microsoft Dynamics, Kinaxis, and Aveva, it provides real-time visibility into:

Demand forecasts and inventory levels.

Production schedules to align material deliveries with manufacturing timelines.

Supplier performance metrics for informed decision-making.

This integration ensures that procurement decisions are data-driven, timely, and aligned with broader organizational goals.

Benefits of PlanetTogether Integration

Enhanced Collaboration: Purchasing managers gain a clear view of production demands, fostering collaboration with production teams and suppliers.

Reduced Waste: Aligning procurement with production needs minimizes overstocking or material shortages, leading to cost savings.

Informed Decision-Making: Real-time data enables smarter decisions, from supplier selection to purchase timing.

Key Steps for Implementing Value-Based Procurement in Medical Manufacturing

Define Procurement Goals

Clearly outline what "value" means for your organization. This could include compliance, innovation, cost savings, or sustainability.

Leverage Integrated Technology

Use tools like PlanetTogether APS integrated with ERP systems to gain real-time insights into supply chain performance and procurement needs.

Evaluate and Select Suppliers

Adopt a comprehensive supplier evaluation process that goes beyond cost to assess quality, reliability, innovation, and sustainability.

Foster Supplier Collaboration

Work closely with suppliers to ensure alignment with your organizational goals. Consider long-term partnerships to drive innovation and cost efficiency.

Monitor and Optimize Performance

Continuously evaluate the performance of procurement strategies using key performance indicators (KPIs) like cost savings, compliance rates, and supplier performance.

Value-based procurement is a paradigm shift for purchasing managers in medical manufacturing. By focusing on overall value rather than just cost, it delivers better outcomes for the organization, its stakeholders, and its customers.

Integrating advanced tools like PlanetTogether APS with ERP systems such as SAP, Oracle, Microsoft Dynamics, Kinaxis, or Aveva is key to unlocking the full potential of this approach. These technologies provide the real-time insights, predictive analytics, and collaboration tools needed to navigate the complexities of modern supply chains.

For purchasing managers ready to embrace this shift, the rewards are immense: improved quality, enhanced compliance, stronger supplier relationships, and a more sustainable, resilient supply chain. Now is the time to lead the charge toward value-based procurement and drive the medical manufacturing industry forward.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.

Topics: PlanetTogether Software, Integrating PlanetTogether, Regulatory Compliance and Quality Assurance, Medical Manufacturing, Cost-effective Innovation, Sustainability and ESG Goals, Resilient Supply Chains

LEAVE A COMMENT