Utilizing Key Performance Indicators (KPIs) for Scheduling in Pharmaceutical Manufacturing

In the pharmaceutical manufacturing industry, achieving operational efficiency while maintaining strict regulatory compliance is paramount. Plant managers are tasked with navigating a complex production environment where time, resources, and quality must be meticulously balanced. One critical tool in their arsenal is the use of Key Performance Indicators (KPIs) for scheduling. By integrating advanced production scheduling software, such as PlanetTogether, with enterprise systems like SAP, Oracle, Microsoft, Kinaxis, or Aveva, plant managers can harness the power of KPIs to optimize production schedules, improve resource utilization, and ensure timely delivery.

KPIs in Pharmaceutical Scheduling

KPIs serve as measurable benchmarks that enable plant managers to assess the efficiency and effectiveness of their scheduling processes. In pharmaceutical manufacturing, where compliance, precision, and quality are non-negotiable, KPIs provide a framework to monitor performance and drive continuous improvement.

Some key KPIs for scheduling in pharmaceutical manufacturing include:

- On-Time Delivery Rate (OTD): Measures the percentage of orders delivered on or before the promised date.

- Production Schedule Adherence: Tracks how closely production follows the planned schedule.

- Changeover Time: Measures the time taken to switch from manufacturing one product to another.

- Equipment Utilization Rate: Evaluates how effectively production equipment is being used.

- Yield Rates: Monitors the percentage of quality products produced relative to the total output.

Challenges in Scheduling Without KPI Integration

Without KPI-driven scheduling, plant managers often encounter several challenges:

Limited Visibility: A lack of real-time data makes it difficult to anticipate bottlenecks or resource shortages.

Inefficient Resource Allocation: Overlapping or conflicting schedules can result in underutilization or overburdening of resources.

Regulatory Risks: Non-compliance with production protocols can lead to costly penalties and damaged reputations.

Suboptimal Decision-Making: Without actionable insights, scheduling decisions may rely on assumptions rather than data.

Leveraging PlanetTogether and ERP Integration

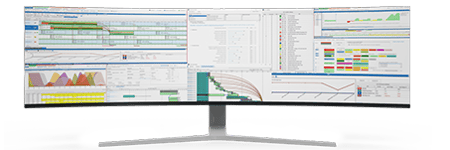

PlanetTogether’s advanced scheduling platform, when integrated with systems like SAP, Oracle, Microsoft Dynamics, Kinaxis, or Aveva, empowers plant managers to overcome these challenges by providing real-time insights, automation, and analytics. This integration creates a seamless flow of data between production schedules and enterprise resource planning systems, enabling plant managers to make data-driven decisions.

Real-Time Data Synchronization

One of the key benefits of integrating PlanetTogether with ERP systems is real-time data synchronization. By connecting shop floor operations with enterprise-level planning, plant managers gain visibility into inventory levels, equipment availability, and workforce schedules. For example, integration with SAP allows production planners to pull live inventory data directly into PlanetTogether, ensuring that materials are allocated efficiently and minimizing the risk of delays caused by stockouts.

Automated KPI Tracking and Alerts

With integrated systems, KPIs can be tracked automatically and presented in customizable dashboards. PlanetTogether can monitor metrics such as production schedule adherence or equipment utilization in real-time, sending alerts when performance deviates from set thresholds. Integration with Oracle’s analytics capabilities further enhances this by providing predictive insights, allowing plant managers to proactively address issues before they escalate.

Enhanced Scenario Planning

Pharmaceutical production often requires rapid adjustments to meet changing demand or address unforeseen disruptions. Integration with Kinaxis enables plant managers to use PlanetTogether’s scenario planning tools to simulate the impact of schedule changes on KPIs. For example, when faced with an urgent order, managers can assess how reassigning resources might affect on-time delivery rates and production costs.

Streamlined Compliance and Reporting

Compliance with Good Manufacturing Practices (GMP) and other regulatory requirements is a critical aspect of pharmaceutical manufacturing. PlanetTogether, when connected to Aveva’s digital engineering solutions, simplifies compliance tracking by linking production schedules with detailed records of equipment maintenance, operator qualifications, and quality checks. This integration ensures that all production activities align with regulatory standards and reduces the administrative burden of preparing audit reports.

Best Practices for KPI-Driven Scheduling

To maximize the benefits of KPI-driven scheduling, plant managers should adopt the following best practices:

Define Relevant KPIs: Select KPIs that align with organizational goals and address specific scheduling challenges in pharmaceutical manufacturing. Focus on metrics that are actionable and directly influence production outcomes.

Standardize Data Collection: Ensure that data inputs across all integrated systems are standardized and accurate. Inconsistent data can lead to erroneous KPI calculations and undermine decision-making.

Leverage Predictive Analytics: Use predictive tools within systems like Kinaxis or Oracle to anticipate future trends and align scheduling strategies accordingly. Predictive insights can help identify potential delays, resource shortages, or equipment failures.

Foster Cross-Functional Collaboration: Scheduling decisions often impact multiple departments, from procurement to quality assurance. Encourage collaboration by providing stakeholders access to KPI dashboards and involving them in scenario planning.

Continuous Improvement: Regularly review KPI performance and use insights to refine scheduling processes. Look for patterns in deviations from targets and implement corrective actions to enhance efficiency over time.

In the dynamic and highly regulated world of pharmaceutical manufacturing, utilizing KPIs for scheduling is no longer optional—it is essential. By integrating advanced scheduling tools like PlanetTogether with robust ERP systems such as SAP, Oracle, Microsoft, Kinaxis, or Aveva, plant managers can unlock new levels of efficiency, compliance, and agility.

The synergy between KPI-driven insights and integrated systems empowers plant managers to navigate scheduling complexities with confidence. With the right tools and practices, they can achieve operational excellence, meet market demands, and maintain the highest standards of quality and compliance.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.