Topics: Waste Reduction, PlanetTogether Software, Integrating PlanetTogether, Process Optimization, Regulatory Compliance and Quality Assurance, Enabling Strategic Decision-Making, Pharmaceutical Manufacturing, Value Stream Mapping

In the dynamic landscape of pharmaceutical manufacturing, where precision, compliance, and efficiency are essential, achieving operational excellence is not just a goal but a necessity. As you oversee the intricate processes within your facility, the pursuit of continuous improvement becomes ever more critical.

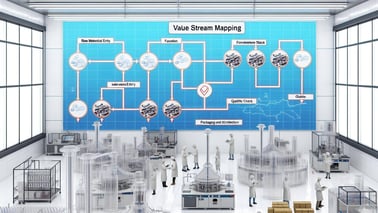

In this blog, we look into a foundational tool that has proven instrumental in optimizing workflows and driving efficiency – Value Stream Mapping (VSM).

At its core, Value Stream Mapping is a visual tool used to analyze and improve the flow of materials and information required to bring a product or service to a customer. Originating from the principles of lean manufacturing, VSM provides a holistic view of the entire production process, from raw material acquisition to the delivery of the final product. By identifying waste, inefficiencies, and bottlenecks, VSM enables organizations to streamline operations and enhance overall performance.

The pharmaceutical industry presents unique challenges, characterized by stringent regulatory requirements, complex supply chains, and the need for meticulous quality control. Plant Managers are tasked with balancing these demands while maintaining cost-effectiveness and agility in operations. In such a dynamic environment, the integration of advanced technologies and data-driven solutions becomes indispensable.

![]()

One standout solution in this realm is PlanetTogether, a comprehensive planning and scheduling software designed to optimize production workflows. By integrating with leading ERP, SCM, and MES systems, PlanetTogether facilitates seamless data exchange and real-time decision-making. Whether it's synchronizing production schedules, managing inventory levels, or mitigating production risks, PlanetTogether empowers Plant Managers to achieve greater operational efficiency and responsiveness.

Now, let's explore the specific benefits that Value Stream Mapping offers to Plant Managers in the pharmaceutical sector:

Waste Reduction: By visually mapping the flow of materials and information, VSM enables the identification and elimination of non-value-added activities, such as excess inventory, overproduction, and waiting times. This lean approach minimizes waste and enhances resource utilization, ultimately driving cost savings and sustainability.

Process Optimization: VSM provides a clear understanding of the interconnected processes within the production ecosystem. Plant Managers can identify bottlenecks, constraints, and inefficiencies, allowing for targeted improvements to enhance throughput and cycle times. This optimization leads to increased productivity and on-time delivery, crucial metrics in pharmaceutical manufacturing.

Compliance and Quality Assurance: In an industry where regulatory compliance is paramount, VSM serves as a valuable tool for ensuring adherence to standards and guidelines. By mapping out the entire value stream, from raw materials to finished products, Plant Managers can implement robust quality control measures and traceability mechanisms. This proactive approach not only mitigates compliance risks but also enhances product quality and patient safety.

Strategic Decision-Making: Armed with actionable insights from VSM, Plant Managers can make informed decisions to drive strategic initiatives and investments. Whether it's expanding production capacity, introducing new technologies, or optimizing supplier relationships, VSM provides the necessary visibility and clarity to prioritize initiatives that align with organizational goals and market demands.

In the pursuit of operational excellence, Value Stream Mapping emerges as a powerful tool for Plant Managers in the pharmaceutical manufacturing sector. By visualizing and optimizing production workflows, VSM enables organizations to reduce waste, enhance efficiency, and ensure compliance with regulatory standards. When integrated with advanced planning and scheduling solutions like PlanetTogether, VSM becomes even more potent, driving real-time decision-making and strategic alignment across the organization.

As the pharmaceutical industry continues to evolve, embracing the principles of Value Stream Mapping and leveraging innovative technologies will be key to unlocking sustainable growth and competitive advantage.

Remember, the journey towards operational excellence is not a destination but a continuous pursuit of improvement and innovation. With Value Stream Mapping as your guide and PlanetTogether as your ally, the possibilities are limitless.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.

Topics: Waste Reduction, PlanetTogether Software, Integrating PlanetTogether, Process Optimization, Regulatory Compliance and Quality Assurance, Enabling Strategic Decision-Making, Pharmaceutical Manufacturing, Value Stream Mapping

0 Comments

No video selected

Select a video type in the sidebar.

LEAVE A COMMENT