Additive Manufacturing in Medical Manufacturing: Enhancing Efficiency with PlanetTogether and ERP Integration

Additive manufacturing (AM), commonly referred to as 3D printing, is revolutionizing the medical manufacturing industry. By enabling rapid prototyping, personalized implants, and efficient production of complex components, AM is driving innovation and cost reduction. However, to fully capitalize on its potential, medical manufacturers must integrate AM workflows with advanced planning and scheduling (APS) systems like PlanetTogether, in conjunction with enterprise resource planning (ERP) systems such as SAP, Oracle, Microsoft, Kinaxis, and Aveva.

For Manufacturing IT managers in medical manufacturing facilities, ensuring seamless integration between AM technology and existing digital infrastructure is key to optimizing production, improving traceability, and maintaining regulatory compliance.

The Role of Additive Manufacturing in Medical Manufacturing

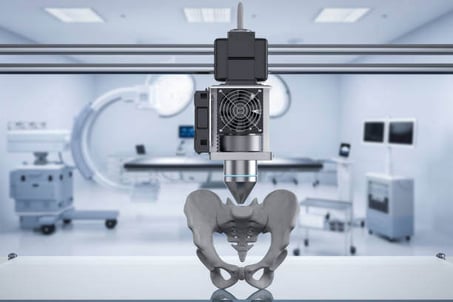

The medical manufacturing sector has embraced additive manufacturing for several applications, including:

Customized Implants and Prosthetics: Patient-specific implants, such as titanium orthopedic implants and dental prosthetics, can be designed and produced efficiently.

Medical Device Prototyping: Rapid prototyping allows for quick iteration and improvement of medical devices.

Bioprinting: The development of bioengineered tissues and organs is advancing, bringing personalized medicine closer to reality.

Surgical Tools and Guides: Custom surgical instruments and preoperative planning models improve precision and outcomes.

Low-Volume Production of Complex Components: AM enables the economical production of intricate geometries that are difficult to manufacture using traditional methods.

Despite its advantages, AM introduces new challenges, such as production scheduling complexities, material tracking, and regulatory requirements. This is where an integrated APS and ERP system can significantly improve efficiency.

Challenges of Additive Manufacturing in Medical Manufacturing

Complex Scheduling and Resource Allocation

AM processes involve multiple stages, including pre-processing, printing, post-processing, and quality inspection.

Scheduling these processes efficiently is critical to minimize downtime and maximize throughput.

Material and Inventory Management

AM requires specialized materials, such as biocompatible polymers, titanium alloys, and resorbable scaffolds.

Maintaining accurate inventory levels and ensuring material traceability is essential for regulatory compliance.

Regulatory Compliance and Quality Control

The medical industry operates under strict FDA, ISO 13485, and GMP guidelines.

Ensuring process validation, documentation, and quality assurance is crucial to meeting industry standards.

Integration with Traditional Manufacturing

Many medical manufacturers operate hybrid production environments that combine AM with traditional machining and injection molding.

Achieving synchronization between AM and conventional workflows requires a unified planning system.

The Role of PlanetTogether APS in Additive Manufacturing

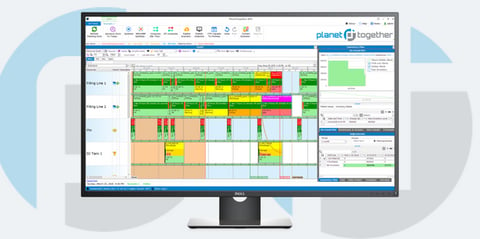

PlanetTogether APS offers advanced scheduling and optimization capabilities tailored to medical manufacturing. Key benefits include:

Dynamic Scheduling & Real-Time Adjustments: PlanetTogether dynamically optimizes AM production schedules, reducing machine idle time and balancing workloads.

Integration with ERP Systems: By connecting with SAP, Oracle, Microsoft, Kinaxis, or Aveva, PlanetTogether ensures seamless data flow across procurement, production, and distribution.

Material and Inventory Optimization: Tracks AM-specific raw materials and automatically updates inventory levels to prevent shortages and overstocking.

Enhanced Traceability & Compliance: Ensures regulatory compliance by maintaining digital records of AM processes, quality checks, and lot tracking.

Predictive Maintenance & Resource Utlization: Uses AI-driven insights to forecast maintenance needs, preventing unexpected downtime and increasing efficiency.

Integrating PlanetTogether APS with ERP Systems

For IT managers, integrating PlanetTogether APS with an ERP system provides a comprehensive approach to managing AM workflows. Here’s how the integration enhances operations:

SAP Integration

Automates order processing for AM production, ensuring seamless procurement of AM materials.

Enables real-time monitoring of production KPIs and compliance tracking.

Oracle Integration

Enhances supply chain visibility for AM components, reducing lead times and optimizing inventory.

Facilitates regulatory documentation and digital workflows for FDA approvals.

Microsoft Integration

Connects AM production data with Power BI for actionable insights and performance analytics.

Utilizes Azure-based cloud solutions for secure and scalable data management.

Kinaxis Integration

Synchronizes demand forecasting with AM production capabilities, ensuring agile supply chain planning.

Provides end-to-end visibility across AM and conventional manufacturing workflows.

Aveva Integration

Incorporates digital twin technology to simulate AM production scenarios and optimize efficiency.

Enables real-time monitoring of AM machines for predictive maintenance and improved uptime.

Additive manufacturing is transforming medical manufacturing, but without proper integration into existing planning and execution systems, its full potential remains untapped. By leveraging PlanetTogether APS in conjunction with ERP solutions like SAP, Oracle, Microsoft, Kinaxis, or Aveva, manufacturers can achieve seamless scheduling, enhanced traceability, and improved resource utilization. For IT managers, enabling these integrations is a strategic move toward digital transformation, ensuring competitiveness in an increasingly complex medical manufacturing landscape.

By embracing a fully integrated approach, medical manufacturers can accelerate innovation, reduce costs, and enhance compliance—positioning themselves at the forefront of the next industrial revolution in healthcare.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.

Topics: PlanetTogether Software, Integrating PlanetTogether, Enables Predictive Maintenance, Medical Manufacturing, Enables Real-time Monitoring of Production KPIs, Facilitates Regulatory Documentation, Provides End-to-End Visibility, Enables Real-time Monitoring of AM Machines

LEAVE A COMMENT