Unlocking Efficiency in Packaging Manufacturing through Setup Time Optimization

In an environment where production lines must accommodate a wide variety of product designs and sizes, the frequent need for changeovers can hinder productivity and increase costs. Setup time, the period required to switch production lines from one task to another, has traditionally been an unavoidable challenge. However, with the advent of modern Manufacturing Execution Systems (MES) and advanced scheduling platforms like PlanetTogether, paired with ERP systems like SAP, Oracle, Microsoft, Kinaxis, or Aveva, reducing setup time is no longer just a hope—it’s a tangible goal.

For Manufacturing IT Managers, reducing setup time through optimized planning and integration can unlock substantial benefits, impacting not just the efficiency of production lines but also the company’s profitability and customer satisfaction.

This blog looks into strategies for setup time optimization in packaging manufacturing, highlighting the advantages of integrating PlanetTogether with leading ERP systems.

Setup Time in Packaging Manufacturing

Setup time, or changeover time, is a significant aspect of any manufacturing process, but it's especially critical in packaging where products frequently vary by size, design, material, and customer requirements. Each changeover requires adjustments to machinery, replacement of tooling, and, in some cases, material changes. These adjustments, even if automated, introduce downtime, reducing the overall output and often disrupting production schedules.

To combat these inefficiencies, manufacturing operations seek to minimize setup time. However, achieving this requires sophisticated scheduling, precise resource allocation, and the flexibility to respond quickly to changes. An integrated MES and ERP ecosystem is essential in streamlining these requirements.

Why Setup Time Optimization Matters

Reducing setup times can bring various advantages to a packaging manufacturer, including:

Improved Production Efficiency: Shorter setup times mean less downtime and increased machine utilization, leading to higher productivity.

Cost Savings: Reduced setup times lower labor and utility costs, contributing to a leaner production process.

Enhanced Flexibility: Quick changeovers make it easier to respond to changes in demand, enabling more efficient handling of small batch sizes or customized packaging runs.

Higher Customer Satisfaction: Faster turnaround times enable quicker delivery to customers, a significant competitive advantage in today’s fast-paced market.

Reduced Inventory Requirements: Efficient setup processes reduce the need for high inventory levels, freeing up cash flow and warehouse space.

PlanetTogether in Setup Time Optimization

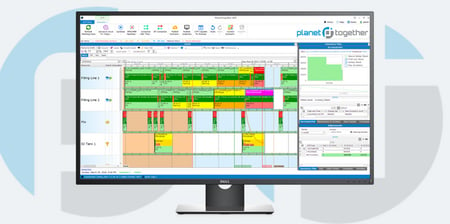

PlanetTogether is a powerful Advanced Planning and Scheduling (APS) software that offers a suite of tools for manufacturers to improve efficiency. When integrated with ERP systems like SAP, Oracle, Microsoft Dynamics, Kinaxis, or Aveva, PlanetTogether provides visibility and control over complex production schedules, allowing for optimized setup times.

Key Features in PlanetTogether for Setup Time Optimization

Sequence Optimization: PlanetTogether enables manufacturers to sequence production runs strategically. For example, it can group similar products together, reducing the need for frequent changeovers and ensuring smoother transitions.

Resource Allocation: With real-time data from integrated ERP systems, PlanetTogether can assign the optimal resources for each production run. This ensures that all necessary tools, materials, and personnel are in place when needed, minimizing delays.

Simulation and What-If Scenarios: PlanetTogether’s simulation capabilities allow planners to assess the impact of different scheduling decisions. This can help identify the best strategies for setup time reduction without sacrificing production quality or throughput.

Real-Time Adjustment: The system allows real-time schedule adjustments in response to unplanned downtime, resource availability, or changing customer demands, minimizing setup time disruptions.

These features, especially when integrated with an ERP system, enable Manufacturing IT Managers to streamline and automate scheduling processes, reducing manual interventions that can contribute to delays.

Integrating PlanetTogether with ERP Systems: How It Enhances Setup Time Optimization

Data Synchronization and Consistency

By integrating PlanetTogether with ERP systems, data related to inventory, order requirements, machine availability, and labor can be synchronized in real time. This ensures consistency between planned schedules and the actual resources available on the production floor. For instance, if SAP or Oracle holds data on material availability, PlanetTogether can use this information to prevent delays during changeovers caused by missing materials.

Improved Scheduling Precision

ERP systems like Microsoft Dynamics or Aveva hold vital information regarding job orders, customer demands, and production capacities. Integrating PlanetTogether with these systems allows it to pull real-time data for precision scheduling, reducing the likelihood of bottlenecks during changeovers. Planners can see the full picture, from inventory levels to machine workloads, and sequence jobs in ways that minimize setup times.

Advanced Analytics and Reporting

With the ERP system acting as a central data repository, the integration with PlanetTogether enables advanced analytics on setup times, bottlenecks, and overall production efficiency. IT Managers can use these insights to identify patterns in setup time delays, helping to implement process improvements and reduce future setup durations.

Automated Alerts and Real-Time Visibility

ERP systems often come with robust alerting mechanisms. When paired with PlanetTogether, these alerts can notify planners and production teams of setup time-related issues. For example, if a machine setup is taking longer than expected, the system can trigger an alert, allowing for immediate intervention to minimize delays.

Practical Steps for IT Managers to Optimize Setup Time with PlanetTogether and ERP Integration

Identify Key Pain Points in Setup Processes Begin by identifying specific issues that cause prolonged setup times. This may include machinery downtime, material shortages, or labor availability issues. Use ERP data to analyze historical data and determine recurring patterns that lead to inefficiencies.

Use Sequence Optimization and Grouping PlanetTogether can be configured to group similar production orders, which can help in reducing the number of setup changes. Coordinate with production and scheduling teams to understand which products can be grouped, taking into account factors like customer priority and material compatibility.

Leverage Real-Time Data for Proactive Decision-Making Utilize real-time data feeds from the ERP system to monitor resource availability. For example, if there is a delay in material delivery recorded in SAP or Oracle, PlanetTogether can adjust the schedule dynamically, avoiding setup times where materials aren’t available.

Train Production Teams on Setup Reduction Techniques With the help of analytics from PlanetTogether and ERP data, conduct training sessions for production teams on SMED (Single Minute Exchange of Dies) or other setup reduction techniques. With clear setup reduction targets, teams can better contribute to the overall goal of minimizing changeover times.

Measure and Analyze Setup Time KPIs Setup time metrics, such as average setup duration, frequency of setup time deviations, and downtime caused by changeovers, are essential KPIs. Leverage the ERP integration to automate these metrics, and use PlanetTogether’s analytics tools to assess progress. These KPIs can also highlight where additional optimization efforts are needed.

In packaging manufacturing, setup time can be a major bottleneck if left unchecked. However, through a combination of advanced scheduling in PlanetTogether and real-time ERP integration with systems like SAP, Oracle, Microsoft, Kinaxis, or Aveva, Manufacturing IT Managers can gain unprecedented control over setup time and its impact on overall productivity.

The investment in an integrated MES and ERP solution goes beyond just software—it empowers manufacturing facilities with data-driven insights, enabling them to move towards a leaner, more agile production environment. As packaging manufacturers increasingly strive to meet evolving customer demands and reduce costs, setup time optimization will be a crucial area where effective IT management and advanced planning tools can make a substantial difference.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.