Utilizing a bad operations scheduling software will only enable you to miss deadlines or waste production time. When you are wasting your time, you are wasting money, which is why it is crucial to make sure that the time you have within your production facilities is utilized to its fullest extent.  When doing this, you must decide whether your priority is speed or timing, and then chose as to which schedule is ideal for your production facility. Once you have considered this, there are three types of operations schedules that your schedule with ultimately fall upon. Therefore, here are three types of operations schedules that your operation may choose from or become apart of.

When doing this, you must decide whether your priority is speed or timing, and then chose as to which schedule is ideal for your production facility. Once you have considered this, there are three types of operations schedules that your schedule with ultimately fall upon. Therefore, here are three types of operations schedules that your operation may choose from or become apart of.

Types of Operations Scheduling

Three types of operations scheduling include the following:

- First Come First Serve - When you have a single item that is being produced, you may decide to go with the first come first serve approach to scheduling. In simpler terms, this type of operations scheduling is concerned with when a customer orders your product. This is effective for operations with a singular product, but overall if you have various products it can be less effective for meeting deadlines.

- Short Processing Time - One of the favored methods of scheduling, this process includes producing products within the shortest processing time. This will prioritize the jobs that will take the least amount of time to finish or complete. This method is also much faster due to you reducing lost time when the machines are switching jobs.

- Earliest Due Date - The Earliest Due Date scheduling process is based on ordering production jobs based on deadlines. When first working on a project, the project with the earliest due date can be effective with machines that have singular jobs and when there are various deadlines spaced out. If you have a business that has one product with diverse shipping deadlines, then this schedule would suit you well.

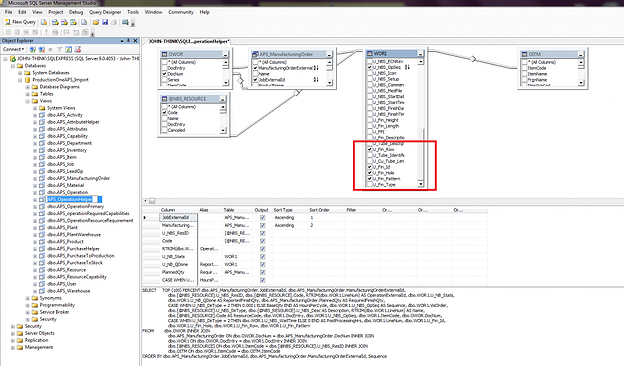

A form of operations scheduling is PlanetTogether’s Advanced Planning and Scheduling Software (APS). Advanced Planning and Scheduling Software is a key component within manufacturing operations that are looking to take their operation to the next level.

Advanced Planning and Scheduling (APS)

Advanced Planning and Scheduling (APS) software has become a must for modern-day manufacturing operations due to customer demand for increased product mix and fast delivery combined with downward cost pressures. APS can be quickly integrated with a ERP/MRP software to fill gaps where these system lack planning and scheduling flexibility and accuracy. Advanced Planning and Scheduling (APS) helps planners save time while providing greater agility in updating ever-changing priorities, production schedules, and inventory plans.

- Create optimized schedules balancing production efficiency and delivery performance

- Maximize output on bottleneck resources to increase revenue

- Synchronize supply with demand to reduce inventories

- Provide company-wide visibility to capacity

- Enable scenario data-driven decision making

Implementation of Advanced Planning and Scheduling (APS) software will take your manufacturing operations to the next level of production efficiency, taking advantage of the operational data you already have in your ERP.

Related What If Video

APS Resources

Topics: Advanced Planning and Scheduling

LEAVE A COMMENT