The Power of Value Creation in Medical Manufacturing

Production planning plays a pivotal role in ensuring that high-quality products reach patients in a timely manner in medical manufacturing. Production planners are the unsung heroes of the manufacturing process, tasked with balancing inventory, meeting customer demands, adhering to strict regulatory requirements, and ensuring that the production line operates smoothly. However, achieving all this within the constraints of time, resources, and budget requires more than just traditional approaches—it demands innovation, integration, and a clear focus on value creation.

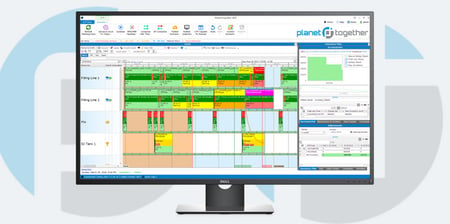

This blog will explore the concept of value creation in medical manufacturing and how leveraging advanced production planning tools like PlanetTogether in conjunction with Enterprise Resource Planning (ERP) systems like SAP, Oracle, Microsoft Dynamics, Kinaxis, and Aveva can significantly enhance a production planner's ability to create value. We’ll delve into the tangible and intangible benefits of integrated systems and show how this synergy helps drive efficiency, compliance, and profitability in a highly competitive industry.

The Meaning of Value Creation in Medical Manufacturing

Value creation refers to the process of enhancing the worth of products, services, or processes in a way that benefits both the company and its customers. In the context of medical manufacturing, value creation can take many forms:

- Improved Patient Outcomes: Ensuring that medical devices, pharmaceuticals, and other healthcare products meet the highest standards of quality and safety, which in turn improves patient outcomes.

- Operational Efficiency: Streamlining production processes to reduce waste, minimize downtime, and optimize resource use.

- Compliance with Regulatory Standards: Adhering to stringent regulations set by bodies like the FDA or EMA, while minimizing the risk of recalls or compliance penalties.

- Cost Reduction: Reducing production costs through more efficient planning, better inventory management, and more accurate forecasting.

For production planners, creating value involves balancing these competing priorities to deliver high-quality products on time, while optimizing the use of labor, materials, and equipment.

The Challenges of Production Planning in Medical Manufacturing

Medical manufacturing is characterized by several unique challenges:

Regulatory Complexity: The production of medical devices and pharmaceuticals is highly regulated. Ensuring compliance while maintaining efficiency can be a daunting task for production planners.

High Product Variability: Medical products often come in a wide variety of configurations, with each variant requiring specific production steps, materials, and quality checks.

Stringent Quality Requirements: Medical products must meet exacting quality standards. A single defect can have serious repercussions, not just for the manufacturer but for patients and healthcare providers.

Inventory Management: Managing inventory in a regulated environment is complex. Medical manufacturers need to ensure that they have the right materials available at the right time while avoiding overstocking or obsolescence, particularly with materials that have a limited shelf life.

Given these challenges, production planners need powerful tools to manage production schedules, track materials, ensure compliance, and optimize workflows. This is where the integration of PlanetTogether with ERP systems comes into play.

![]()

The Role of PlanetTogether in Production Planning

PlanetTogether is an Advanced Planning and Scheduling (APS) solution that helps manufacturers optimize their production schedules by providing real-time visibility, powerful scheduling algorithms, and analytics capabilities. The system is particularly well-suited for industries like medical manufacturing, where precision, compliance, and efficiency are critical.

With PlanetTogether, production planners can:

Create Optimal Schedules: PlanetTogether’s algorithms help planners create schedules that optimize the use of available resources, minimize downtime, and ensure on-time delivery. This is particularly valuable in medical manufacturing, where delays can impact patient care.

Improve Visibility: PlanetTogether provides real-time visibility into production processes, allowing planners to see potential bottlenecks before they become problems. This visibility is essential for maintaining the high levels of efficiency required in a competitive industry.

Enhance Collaboration: By integrating with ERP systems, PlanetTogether facilitates communication and collaboration between different departments, including production, procurement, and quality control.

Respond to Changes: In a dynamic environment like medical manufacturing, the ability to quickly respond to changes in demand, supply chain disruptions, or equipment failures is crucial. PlanetTogether enables planners to adjust schedules in real-time, ensuring that production stays on track even in the face of unexpected challenges.

Why Integrate PlanetTogether with ERP Systems?

While PlanetTogether offers powerful production planning capabilities, its true potential is unlocked when it is integrated with ERP systems like SAP, Oracle, Microsoft Dynamics, Kinaxis, and Aveva. These ERP systems provide a central repository of data related to finance, procurement, inventory, and human resources, among other functions. By integrating PlanetTogether with an ERP system, medical manufacturers can achieve a seamless flow of information across the organization, enhancing decision-making and driving value creation.

Key Benefits of Integration

Improved Data Accuracy and Consistency: Integrating PlanetTogether with an ERP system ensures that all departments are working from the same data. This reduces the risk of errors caused by outdated or inconsistent information, which can lead to production delays or compliance issues in medical manufacturing.

Enhanced Inventory Management: When PlanetTogether is integrated with an ERP system, production planners can access real-time inventory data. This allows them to ensure that the right materials are available when needed, reducing the risk of stockouts or excess inventory. In medical manufacturing, where material shortages can delay production or impact product quality, this is particularly critical.

Streamlined Compliance: Medical manufacturing is subject to stringent regulatory requirements. By integrating PlanetTogether with an ERP system, manufacturers can ensure that production processes are fully traceable and compliant with regulatory standards. For example, integration with SAP or Oracle can help ensure that all production activities are properly documented, which is essential for meeting FDA requirements.

Improved Resource Utilization: PlanetTogether’s scheduling capabilities, combined with the resource management capabilities of ERP systems like Microsoft Dynamics or Aveva, help production planners ensure that labor, equipment, and materials are used as efficiently as possible. This not only reduces costs but also helps manufacturers meet their production goals on time.

Enhanced Decision-Making: When PlanetTogether is integrated with an ERP system, production planners have access to a wealth of data that can inform their decisions. For example, they can view real-time financial data from SAP or Oracle to understand the cost implications of different production schedules, or use demand forecasting data from Kinaxis to adjust production plans based on changing market conditions.

Real-Time Adjustments: The integration allows for real-time adjustments to production plans in response to changing conditions. For example, if a material shortage is detected in the ERP system, PlanetTogether can automatically adjust the production schedule to minimize disruption. This agility is essential in the fast-paced medical manufacturing industry.

Best Practices for Successful Integration

To maximize the value of integrating PlanetTogether with an ERP system, medical manufacturers should follow these best practices:

Align Stakeholders: Ensure that all relevant departments—production, procurement, finance, and quality control—are aligned and understand the goals of the integration. This will help avoid potential conflicts and ensure that the integration meets the needs of all stakeholders.

Start Small: Begin with a pilot project to test the integration and work out any issues before rolling it out across the entire organization. This approach allows for a smoother transition and helps build confidence in the system.

Invest in Training: Provide training for production planners and other staff on how to use the integrated system effectively. This will help ensure that the integration delivers the intended benefits.

Monitor and Optimize: After the integration is complete, continue to monitor its performance and look for opportunities to optimize the system. Regularly reviewing key performance indicators (KPIs) will help identify areas for further improvement.

The Future of Value Creation in Medical Manufacturing

As the medical manufacturing landscape continues to evolve, the role of production planners will become even more central to a company’s success. Emerging trends such as the adoption of Industry 4.0 technologies, increased focus on sustainability, and the use of artificial intelligence (AI) and machine learning in predictive analytics will further enhance the value that production planners can create.

Industry 4.0 Integration: The integration of PlanetTogether with ERP systems is just the beginning. The rise of Industry 4.0, characterized by smart factories, the Internet of Things (IoT), and cyber-physical systems, will create new opportunities for value creation in medical manufacturing. For example, by integrating IoT-enabled machines with PlanetTogether and an ERP system, production planners can receive real-time updates on machine performance and make adjustments on the fly to avoid downtime or equipment failures.

Sustainability Initiatives: As sustainability becomes an increasing priority for both regulators and consumers, medical manufacturers will need to find ways to reduce waste, energy consumption, and carbon emissions. PlanetTogether’s optimization algorithms, when integrated with an ERP system, can help manufacturers minimize waste by ensuring that materials are used efficiently and production schedules are designed to reduce energy consumption. This not only creates environmental value but also reduces costs, enhancing the overall value proposition.

AI and Predictive Analytics: AI and machine learning have the potential to revolutionize production planning by providing advanced predictive analytics that can anticipate demand fluctuations, supply chain disruptions, or equipment failures before they occur. By integrating these capabilities with PlanetTogether and an ERP system like Kinaxis, production planners can gain deeper insights into future challenges and opportunities, allowing them to create more robust, value-driven production plans.

Personalized Medicine: The increasing shift toward personalized medicine, where treatments and devices are tailored to individual patients, will require more flexible and agile manufacturing processes. In this context, production planners will need to be able to quickly adjust production schedules and materials to accommodate highly customized orders. PlanetTogether’s ability to rapidly respond to changes in demand and integrate seamlessly with ERP systems will be essential in enabling manufacturers to meet the demands of personalized medicine.

For production planners in medical manufacturing facilities, the pressure to balance efficiency, compliance, and cost-effectiveness has never been greater. However, by embracing the integration of advanced planning tools like PlanetTogether with ERP systems such as SAP, Oracle, Microsoft Dynamics, Kinaxis, and Aveva, production planners can unlock unprecedented levels of value creation.

The benefits of integration are clear: better visibility, improved efficiency, enhanced compliance, and more accurate decision-making. In an industry where the margin for error is small and the stakes are high, these capabilities can make the difference between success and failure.

The role of production planners will become even more critical. Those who leverage the power of integrated systems will be well-positioned to create value not just for their organizations, but for the patients who rely on the medical products they produce.

The future of medical manufacturing is bright for those who embrace integration, innovation, and the relentless pursuit of value creation. Production planners, armed with tools like PlanetTogether and ERP integration, will continue to play a central role in driving that future forward.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.

Topics: PlanetTogether Software, Improved Resource Utilization, Enhanced Decision Making, Enhanced Inventory Management, Real-time Adjustments, Integrating PlanetTogether, Medical Manufacturing, Improved Data Accuracy and Consistency, Streamlined Compliance

LEAVE A COMMENT