The Digitalization of Process Workflow Automation

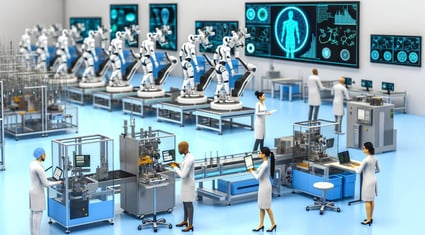

The integration of digital technologies has become imperative for staying competitive, efficient, and compliant in medical manufacturing. Traditional methods of production are being replaced by sophisticated digital solutions, streamlining processes, reducing costs, and improving overall productivity. At the heart of this transformation lies the digitalization of manufacturing process workflow automation, a concept that is reshaping the industry's approach to production management.

In this blog, we will look into the significance of digitalization in medical manufacturing, exploring its impact on the workflow automation process. Specifically, we will highlight the integration between PlanetTogether, a leading production planning and scheduling software, and prominent ERP, SCM, and MES systems such as SAP, Oracle, Microsoft, Kinaxis, and Aveva. Let's embark on this journey towards a more efficient and technologically advanced future for medical manufacturing.

Digitalization in Manufacturing

Digitalization in manufacturing refers to the integration of digital technologies into every aspect of the production process, from design and planning to execution and analysis. It involves the use of advanced software solutions, data analytics, and automation to optimize operations, enhance decision-making, and drive innovation.

One of the key components of digitalization is process workflow automation. By automating repetitive tasks, optimizing resource allocation, and synchronizing production schedules, manufacturers can achieve higher levels of efficiency, accuracy, and agility. This not only reduces lead times and production costs but also enables faster time-to-market and better responsiveness to customer demands.

Integration of PlanetTogether with ERP, SCM, and MES Systems

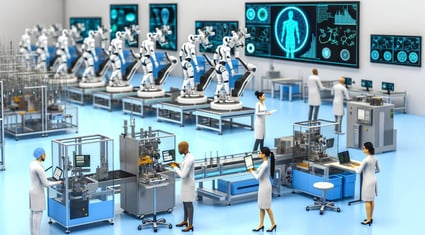

PlanetTogether is a powerful production planning and scheduling software that enables manufacturers to create optimized production schedules, allocate resources effectively, and manage capacity constraints. Its advanced algorithms and intuitive interface make it a preferred choice for companies seeking to streamline their production processes and improve overall efficiency.

However, to fully harness the capabilities of PlanetTogether, integration with other enterprise systems such as ERP (Enterprise Resource Planning), SCM (Supply Chain Management), and MES (Manufacturing Execution Systems) is essential. These systems act as the backbone of manufacturing operations, managing critical data related to inventory, orders, resources, and production workflows.

Integration between PlanetTogether and leading ERP, SCM, and MES systems such as SAP, Oracle, Microsoft, Kinaxis, and Aveva allows for seamless data exchange and real-time synchronization across different functional areas. This integration unlocks several benefits for medical manufacturing facilities, including:

Enhanced Visibility and Collaboration: By integrating PlanetTogether with ERP, SCM, and MES systems, manufacturers gain a comprehensive view of their entire production ecosystem. Real-time data exchange enables stakeholders to collaborate more effectively, anticipate potential bottlenecks, and make informed decisions to optimize production processes.

Improved Production Planning and Scheduling: The integration of PlanetTogether with ERP systems provides access to critical information such as customer orders, inventory levels, and resource availability. This allows manufacturers to generate more accurate production schedules, prioritize orders based on demand, and allocate resources efficiently to meet delivery deadlines.

Efficient Resource Management: With integrated data from ERP, SCM, and MES systems, PlanetTogether can dynamically adjust production schedules based on resource availability and capacity constraints. This ensures optimal utilization of equipment, manpower, and materials, minimizing downtime and maximizing productivity.

Compliance and Quality Assurance: By maintaining a centralized repository of production data, integrated systems facilitate compliance with regulatory requirements and quality standards in the medical manufacturing industry. Automated workflows and real-time monitoring help identify deviations from specifications early on, preventing costly errors and ensuring product quality and safety.

Agility and Adaptability: In today's fast-paced market environment, agility and adaptability are critical for staying competitive. Integration between PlanetTogether and ERP, SCM, and MES systems enables manufacturers to quickly respond to changes in demand, supply chain disruptions, and unforeseen events, ensuring continuity of operations and customer satisfaction.

The digitalization of manufacturing process workflow automation represents a paradigm shift in the medical manufacturing industry, offering unprecedented opportunities for efficiency, innovation, and competitiveness. By integrating advanced software solutions like PlanetTogether with ERP, SCM, and MES systems, manufacturers can unlock new levels of productivity, agility, and quality in their operations.

As we continue to embrace digital transformation, collaboration between technology providers, manufacturers, and regulatory bodies will be essential to drive standardization, interoperability, and best practices across the industry. Together, we can pave the way for a more resilient, sustainable, and technologically advanced future for medical manufacturing.

The journey towards digitalization may seem daunting, but the rewards are well worth the investment. By embracing change and leveraging the power of digital technologies, medical manufacturers can position themselves for long-term success in an increasingly competitive and dynamic market landscape.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.

LEAVE A COMMENT