Autonomous Inspection Systems for Quality Assurance

Companies are continuously seeking ways to enhance their quality assurance processes. With technological advancements in artificial intelligence (AI), machine learning (ML), and sensor technologies, autonomous inspection systems have emerged as a game-changer for quality control. They can substantially reduce human error, cut costs, and improve overall product quality.

This blog will discuss how integrating PlanetTogether’s advanced planning and scheduling software with ERP, SCM, and MES systems like SAP, Oracle, Microsoft, Kinaxis, and Aveva can streamline the deployment of autonomous inspection systems for quality assurance in manufacturing.

Understanding Autonomous Inspection Systems

Autonomous inspection systems are quality control tools that utilize AI and ML to analyze product defects and deviations automatically. They leverage sensors, cameras, and other devices to capture data from manufactured products and then compare these data points against predefined standards to identify any quality issues.

Key Features

Non-Destructive Testing (NDT): Advanced imaging technology allows for comprehensive analysis without damaging products.

Real-Time Analysis: Immediate data collection and analysis enable rapid decision-making and defect resolution.

Adaptive Learning: Systems improve their accuracy over time by learning from previous inspections.

Benefits of Autonomous Inspection Systems

Implementing autonomous inspection systems can yield the following benefits:

Improved Accuracy: Autonomous systems identify defects with greater precision than human inspectors, resulting in higher product quality.

Faster Inspection: Automated inspections are quicker than manual checks, which reduces the inspection bottleneck and speeds up production.

Reduced Costs: Less labor is required, and fewer defective products reach customers, minimizing costly recalls and rework.

![]()

PlanetTogether: A Key Integrator for Quality Assurance

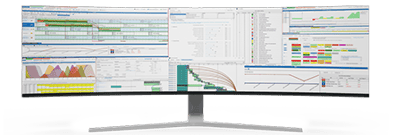

PlanetTogether is an advanced planning and scheduling (APS) software that integrates with ERP, SCM, and MES systems to provide holistic production planning. Its real-time data integration helps manufacturers optimize production schedules and align quality assurance processes with production goals. By incorporating autonomous inspection data into PlanetTogether, manufacturers can gain actionable insights into their quality assurance strategies.

Integration with ERP, SCM, and MES Systems

Integrating autonomous inspection systems into ERP, SCM, and MES systems like SAP, Oracle, Microsoft, Kinaxis, and Aveva ensures seamless data flow across the manufacturing ecosystem.

SAP

-

- PlanetTogether seamlessly integrates with SAP’s ERP to synchronize inspection results with production planning.

- Autonomous inspection data can be used to trigger SAP’s quality management module for further analysis or corrective actions.

Oracle

- Oracle’s SCM and ERP systems combined with PlanetTogether’s scheduling tools allow for comprehensive tracking of quality issues.

- Inspection data flows into Oracle’s quality control tools, providing comprehensive audit trails.

Microsoft

- PlanetTogether works with Microsoft Dynamics to align quality assurance with production goals, ensuring rapid response to quality issues.

- Automated inspection data enables tighter control over supply chain quality, improving supplier performance.

Kinaxis

- Kinaxis integrates inspection data into its RapidResponse platform, providing holistic supply chain insights.

- Autonomous inspection systems help monitor production issues across global networks.

Aveva

- Aveva’s MES integrates seamlessly with PlanetTogether for production planning while managing inspection data efficiently.

- Real-time inspection data can trigger alerts, ensuring immediate resolution of quality issues.

Practical Implementation Strategies

Successfully implementing autonomous inspection systems requires careful planning and alignment with overall business goals. Here are some practical steps:

Assessment and Pilot Testing

-

- Conduct a comprehensive assessment of current quality assurance processes.

- Identify specific areas where autonomous inspection can add value.

- Initiate pilot testing on a limited product range to evaluate effectiveness.

Data Integration

- Ensure autonomous inspection systems can easily integrate with existing ERP, SCM, and MES systems.

- Collaborate with system integrators like PlanetTogether to streamline data flows and avoid duplication.

Customization

- Customize inspection algorithms and data analysis according to specific product requirements.

- Leverage AI and ML to refine defect identification criteria.

Change Management

- Educate the workforce on the benefits of autonomous inspection and how it improves quality assurance.

- Provide training to ensure smooth adoption.

Continuous Improvement

- Monitor inspection results and use feedback to improve both the system and product quality.

- Periodically review and update inspection criteria.

Future Outlook: Moving Towards Total Quality Control

The future of autonomous inspection systems is bright as manufacturers aim for total quality control. Upcoming trends include:

Predictive Maintenance

-

- Autonomous systems will increasingly identify machine maintenance needs, preventing quality issues before they arise.

Integrated Robotics

- Inspection robots will directly interact with production robots, enabling fully autonomous production lines.

Augmented Reality (AR)

- AR will provide real-time visualization of inspection data, helping operators quickly understand and act on quality issues.

Edge Computing

- Edge computing will process inspection data at the source, reducing latency and improving response times.

Supply Chain Visibility

- Autonomous inspection data will be integrated into supply chain analytics, providing end-to-end quality visibility.

Autonomous inspection systems represent a significant step forward in quality assurance for manufacturing. By integrating these systems with ERP, SCM, and MES tools like SAP, Oracle, Microsoft, Kinaxis, and Aveva through PlanetTogether, manufacturers can seamlessly align quality control with production planning. This integration not only reduces costs and improves accuracy but also enhances overall supply chain efficiency.

As technology evolves, autonomous inspection systems will become a cornerstone of total quality control, offering new levels of precision and reliability in manufacturing processes.

With continuous improvement, data integration, and workforce training, autonomous inspection systems will undoubtedly redefine the future of quality assurance in manufacturing.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.

Topics: Industrial Manufacturing, PlanetTogether Software, Integrating PlanetTogether, Improved Accuracy, Autonomous Inspection Systems, Tracking of Quality Issues, Seamlessly integration, Rapid Response to Quality Issues

LEAVE A COMMENT