The Advancement of Digital and Analytics Tools in Pharmaceutical Manufacturing

The pharmaceutical industry is navigating a transformative era, driven by the need for precision, compliance, and efficiency. As a Plant Manager in a pharmaceutical manufacturing facility, you’re likely familiar with the pressures of meeting rigorous production standards while maintaining cost-effectiveness.

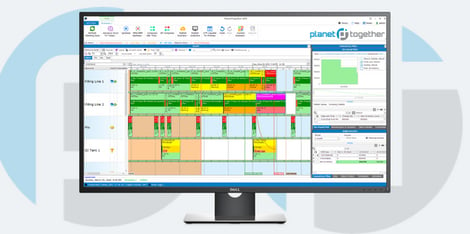

One of the most compelling solutions to these challenges is the integration of advanced digital and analytics tools. By leveraging platforms like PlanetTogether in conjunction with enterprise resource planning (ERP) systems such as SAP, Oracle, Microsoft, Kinaxis, or Aveva, your facility can achieve unprecedented levels of operational excellence.

The Shift Toward Digitalization in Pharmaceutical Manufacturing

Digital transformation is no longer optional in pharmaceutical manufacturing. The shift toward Industry 4.0 has brought technologies such as the Internet of Things (IoT), Artificial Intelligence (AI), and advanced analytics to the forefront. These innovations enable manufacturers to optimize production processes, improve product quality, and ensure regulatory compliance.

For plant managers, digital tools provide actionable insights that streamline operations and enhance decision-making. For example, predictive analytics can forecast potential equipment failures, reducing downtime and maintaining production schedules. Similarly, real-time monitoring systems can ensure compliance with Good Manufacturing Practices (GMP) by identifying and addressing deviations as they occur.

Role of Analytics in Optimizing Pharmaceutical Manufacturing

Analytics tools offer a data-driven approach to manufacturing, enabling the identification of inefficiencies and areas for improvement. Key benefits of analytics in pharmaceutical production include:

Improved Batch Yields: Advanced analytics can pinpoint factors affecting batch consistency, helping to optimize formulations and processes.

Enhanced Quality Assurance: By analyzing trends and anomalies in production data, analytics tools help identify quality risks before they escalate.

Resource Optimization: Analytics platforms can model production scenarios to optimize the use of raw materials, labor, and equipment.

Integration of PlanetTogether with Leading ERP Systems

While digital tools are powerful on their own, their true potential is unlocked when integrated into a cohesive ecosystem. PlanetTogether’s advanced planning and scheduling (APS) capabilities seamlessly integrate with ERP systems like SAP, Oracle, Microsoft Dynamics, Kinaxis, and Aveva, creating a unified framework for production planning and execution.

Key Advantages of Integration:

Real-Time Visibility: Integration provides a single source of truth for production data, enabling plant managers to monitor operations in real time.

Improved Scheduling: By combining PlanetTogether’s APS functionality with ERP data, you can generate optimized production schedules that account for constraints such as equipment availability, labor shifts, and material supply.

Enhanced Collaboration: Integrated systems foster collaboration across departments, ensuring that everyone from procurement to quality assurance is aligned with production goals.

Scalability: As your facility grows, integrated systems can easily scale to accommodate increased complexity and volume.

Practical Applications of Digital and Analytics Tools

Predictive Maintenance

With IoT sensors and analytics, plant managers can monitor equipment performance in real time. Predictive maintenance algorithms analyze historical and real-time data to forecast potential equipment failures, allowing for timely interventions. This not only minimizes downtime but also extends the lifespan of critical assets.

Process Optimization

Advanced analytics tools can model various production scenarios, helping to identify the most efficient workflows. By leveraging digital twins—virtual replicas of physical processes—plant managers can test process changes without disrupting actual production.

Quality Control

Digital tools enable continuous quality monitoring by integrating data from production lines, lab tests, and environmental controls. Machine learning algorithms can detect subtle patterns that might indicate quality risks, allowing for proactive measures.

Inventory Management

Integrated systems provide real-time insights into inventory levels, ensuring that raw materials and finished goods are optimally stocked. Analytics tools can forecast demand patterns, reducing the risk of stockouts or overproduction.

As a Plant Manager in a pharmaceutical manufacturing facility, embracing the advancement of digital and analytics tools is essential for staying competitive in a rapidly evolving industry. By integrating PlanetTogether with ERP systems like SAP, Oracle, Microsoft, Kinaxis, or Aveva, you can unlock the full potential of these technologies. From predictive maintenance and process optimization to quality control and inventory management, digital tools provide the insights and capabilities needed to drive operational excellence.

Now is the time to act. Evaluate your facility’s current capabilities, identify areas for improvement, and invest in the digital and analytics tools that will position your facility for long-term success. With the right strategy and tools in place, you can achieve a new level of efficiency, compliance, and innovation in pharmaceutical manufacturing.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.