Supply Chain Digitalization for Enhancing Performance and Resilience

The pharmaceutical industry operates under tight regulations, stringent quality control, and a volatile supply chain environment. As a Supply Chain Manager in a pharmaceutical manufacturing facility, you know all too well the complexities of balancing compliance, cost, and efficiency while ensuring continuous operations in a high-stakes environment. This is why digitalizing the supply chain is not just an option but a necessity for achieving enhanced performance and resilience.

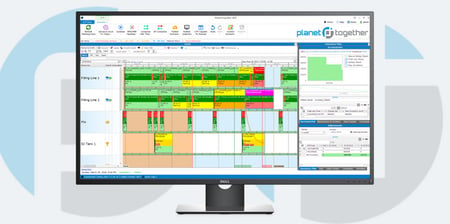

In this blog, we will explore how supply chain digitalization can transform pharmaceutical manufacturing and discuss the integration of advanced planning and scheduling systems like PlanetTogether with major enterprise resource planning (ERP) systems such as SAP, Oracle, Microsoft Dynamics, Kinaxis, and Aveva. These integrations can unlock new capabilities, giving you the tools to maintain agility, streamline operations, and enhance supply chain resilience in a dynamic and highly regulated industry.

The Need for Supply Chain Digitalization

Pharmaceutical supply chains are unique in their complexity. They must respond to fluctuating demand patterns, stringent regulatory requirements, temperature-sensitive storage needs, and long lead times for sourcing raw materials. The COVID-19 pandemic underscored the need for increased supply chain resilience, exposing vulnerabilities such as over-reliance on single suppliers and inadequate visibility into the extended supply chain.

Traditional supply chain management methods relying on manual processes and disconnected systems are no longer sufficient to meet the demands of this new era. Pharmaceutical companies are increasingly turning to digital tools that can provide real-time data visibility, improve decision-making, and ensure that disruptions are anticipated and mitigated quickly.

How Digitalization Enhances Supply Chain Performance

The digitalization of supply chain processes can provide pharmaceutical manufacturers with several key benefits:

Real-Time Visibility: Digital platforms provide end-to-end visibility across the supply chain, enabling better tracking of raw materials, work-in-progress, and finished products. This transparency helps pharmaceutical manufacturers monitor critical data points such as lead times, inventory levels, and compliance requirements.

Data-Driven Decision Making: Supply chain digitalization enables the use of data analytics and machine learning algorithms to make informed, evidence-based decisions. Advanced analytics can identify bottlenecks, forecast demand with greater accuracy, and provide predictive insights that allow companies to be more proactive.

Process Automation: Digital tools allow for the automation of many manual tasks, such as order processing, inventory management, and compliance tracking. This reduces errors, improves efficiency, and frees up your team to focus on higher-value tasks.

Enhanced Collaboration: By connecting all stakeholders on a digital platform, supply chain partners—from suppliers to manufacturers to logistics providers—can collaborate in real time. This collaborative approach improves information sharing, reduces communication delays, and fosters a more agile supply chain network.

Resilience and Risk Mitigation: Digitalization allows for real-time risk assessments and scenario planning, helping pharmaceutical companies anticipate potential disruptions and mitigate risks before they affect operations. By using tools that can simulate different supply chain scenarios, companies can build more resilient supply chains that are better prepared to handle unexpected events.

The Role of Advanced Planning and Scheduling (APS) in Pharmaceutical Supply Chains

Advanced planning and scheduling (APS) systems like PlanetTogether play a crucial role in optimizing supply chain performance in pharmaceutical manufacturing. APS systems enable manufacturers to efficiently plan production schedules, manage inventory, and balance supply and demand across the supply chain.

Key capabilities of APS systems include:

Optimized Production Planning: APS systems use real-time data and advanced algorithms to optimize production schedules. This ensures that production is aligned with demand, reduces lead times, and minimizes excess inventory while avoiding stockouts.

Capacity Management: APS systems help manufacturers manage production capacity more effectively, allowing them to adapt quickly to changes in demand without overloading resources or compromising quality.

Scenario Planning: Pharmaceutical manufacturers can use APS systems to simulate different production and supply chain scenarios. This enables them to anticipate potential disruptions and plan accordingly, enhancing supply chain resilience.

Compliance Tracking: Compliance with regulatory requirements is essential in the pharmaceutical industry. APS systems can integrate compliance tracking into the production process, ensuring that all necessary quality control measures are followed.

Integrating PlanetTogether with ERP Systems: Enhancing Performance and Collaboration

The integration of PlanetTogether with leading ERP systems like SAP, Oracle, Microsoft Dynamics, Kinaxis, and Aveva can further enhance supply chain performance and resilience by providing seamless data flow and improving decision-making capabilities. Here’s how such integration can benefit your supply chain operations:

Integration with SAP: Enhancing Efficiency and Accuracy

SAP is one of the most widely used ERP systems in the pharmaceutical industry, offering comprehensive modules for managing production, inventory, and quality control. By integrating PlanetTogether with SAP, pharmaceutical companies can synchronize their production planning and scheduling data with their broader ERP system, ensuring that real-time information is shared across departments.

For example, PlanetTogether’s advanced scheduling algorithms can optimize production schedules based on real-time demand and resource availability, while SAP manages order fulfillment, procurement, and financials. This integration ensures that production plans are aligned with inventory levels and demand forecasts, minimizing the risk of stockouts or overproduction. Moreover, any changes in production schedules or inventory levels are automatically reflected in both systems, reducing manual data entry and the risk of errors.

Integration with Oracle: Driving Agility in Supply Chain Management

Oracle’s ERP solutions are known for their robust capabilities in supply chain management, including inventory optimization, demand forecasting, and supplier collaboration. Integrating PlanetTogether with Oracle enables pharmaceutical manufacturers to leverage the power of advanced planning and scheduling to create more agile supply chains.

By connecting PlanetTogether’s APS system with Oracle, pharmaceutical companies can create dynamic production schedules that respond to real-time changes in demand and supply. For example, if a supplier delay occurs, the integration allows the production schedule to be automatically adjusted, minimizing downtime and ensuring that production continues smoothly. The integration also improves collaboration between procurement and production teams by providing a unified view of inventory levels, supplier lead times, and production schedules.

Integration with Microsoft Dynamics: Streamlining Operations and Enhancing Decision Making

Microsoft Dynamics is a popular choice for pharmaceutical companies due to its flexibility and scalability. Integrating PlanetTogether with Microsoft Dynamics allows for real-time synchronization of production schedules, inventory levels, and demand forecasts.

With this integration, pharmaceutical manufacturers can use PlanetTogether’s APS capabilities to optimize production schedules and then automatically update inventory and procurement data in Microsoft Dynamics. This ensures that all teams have access to the latest data, reducing the risk of miscommunication or production delays. Additionally, the integration allows for more effective decision-making, as managers can use the real-time data from both systems to identify trends, forecast demand, and plan for future growth.

Integration with Kinaxis: Improving Demand and Supply Balancing

Kinaxis specializes in supply chain planning and execution, providing tools for demand forecasting, inventory optimization, and supplier collaboration. By integrating PlanetTogether with Kinaxis, pharmaceutical manufacturers can create a seamless connection between production planning and supply chain management.

This integration enables manufacturers to balance demand and supply more effectively. For example, PlanetTogether’s scheduling capabilities can be used to create optimized production plans based on real-time demand data from Kinaxis. This ensures that production is aligned with actual demand, reducing the risk of overproduction or stockouts. The integration also improves communication between production and procurement teams, ensuring that raw materials are ordered in time to meet production needs.

Integration with Aveva: Enhancing Operational Efficiency through Predictive Analytics

Aveva’s solutions for the pharmaceutical industry focus on operational efficiency, process optimization, and asset management. Integrating PlanetTogether with Aveva allows pharmaceutical manufacturers to leverage predictive analytics and real-time data to optimize production schedules and improve operational efficiency.

For example, Aveva’s predictive maintenance capabilities can be used to identify potential equipment failures before they occur, allowing production schedules to be adjusted accordingly. PlanetTogether can then use this data to create optimized production schedules that take into account equipment availability and maintenance needs. This integration ensures that production runs smoothly, with minimal disruptions, while maximizing equipment utilization.

In the pharmaceutical industry, supply chain resilience and performance are critical to ensuring the timely delivery of life-saving medications. Digitalizing your supply chain with advanced tools like PlanetTogether and integrating them with ERP systems such as SAP, Oracle, Microsoft Dynamics, Kinaxis, and Aveva can provide your organization with the agility, visibility, and decision-making power it needs to thrive in today’s challenging environment.

By embracing supply chain digitalization, you can enhance operational efficiency, improve collaboration across the supply chain, and build the resilience needed to navigate disruptions and changes in demand. For pharmaceutical manufacturers, this digital transformation is not just a competitive advantage but a necessity for maintaining quality, compliance, and patient trust in an increasingly complex world.

As a Supply Chain Manager, the time to invest in digitalization is now. Whether you're looking to optimize production, enhance collaboration with suppliers, or mitigate risks, integrating PlanetTogether with your existing ERP system can unlock the potential of your supply chain, ensuring it is equipped to meet the challenges of today and tomorrow.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.