Smart Supply Chains in Industrial Manufacturing: The Future of Agile, Intelligent Operations

Industrial manufacturing is undergoing a digital transformation. Once characterized by siloed operations and manual processes, supply chains in this sector are now being reshaped by smart technologies—bringing enhanced visibility, responsiveness, and optimization. For Supply Chain Managers, this evolution presents both an opportunity and a challenge: to harness smart supply chain capabilities that ensure resilience, reduce cost, and support dynamic customer demands.

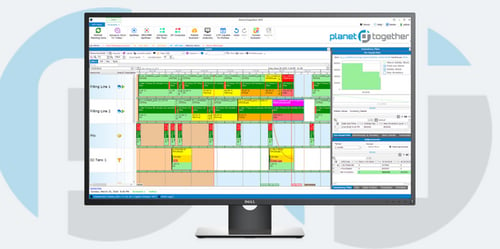

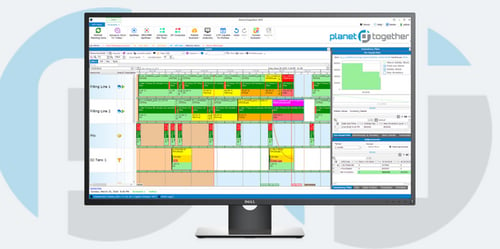

At the heart of this transformation is Advanced Planning and Scheduling (APS) software like PlanetTogether, which—when integrated with ERP giants such as SAP, Oracle, Microsoft, Kinaxis, and Aveva—serves as the digital backbone of intelligent operations.

What is a Smart Supply Chain?

A smart supply chain uses data, automation, artificial intelligence (AI), and real-time communication to manage and optimize operations across the end-to-end supply network. It allows for:

Real-time visibility across all supply chain nodes

Predictive analytics to foresee disruptions

Automated decision-making to speed up responsiveness

Integrated planning and execution between systems

By integrating smart technologies into core manufacturing operations, industrial organizations are evolving from reactive to proactive supply chain management.

Why Smart Supply Chains Matter in Industrial Manufacturing

Industrial manufacturing is particularly sensitive to supply and demand fluctuations, equipment availability, and global sourcing complexity. These factors contribute to:

Rising operational costs

Longer lead times

Inventory imbalances

Higher risk exposure

A smart supply chain mitigates these challenges by unifying production, logistics, and procurement processes—creating an agile system that can adapt to volatility without sacrificing performance or profitability.

Enabling the Smart Supply Chain with PlanetTogether APS

PlanetTogether serves as the nerve center for smart supply chains by enabling real-time planning, scheduling, and optimization. Its power is amplified when it integrates with ERP systems like:

SAP: Combining master data and transactional integrity with APS-based capacity planning and order prioritization.

Oracle: Offering dynamic scheduling and constraint management layered onto enterprise-wide resource planning.

Microsoft Dynamics 365: Uniting operational control with AI-driven scheduling to align demand with production capacity.

Kinaxis: Enhancing supply chain agility with synchronized planning and responsive execution.

Aveva: Bridging manufacturing operations and planning tools for energy-efficient, sustainable supply networks.

This integration enables end-to-end visibility and cross-functional synchronization, allowing supply chain managers to make decisions not just faster—but smarter.

Key Capabilities of a Smart Supply Chain with Integrated APS

Dynamic Demand Forecasting

Smart supply chains use machine learning to generate accurate forecasts based on market data, customer behavior, and historical trends. When these forecasts feed into PlanetTogether, they drive:

Agile scheduling

Just-in-time inventory management

Optimized procurement planning

Predictive Maintenance and Asset Scheduling

Connected IoT devices can predict equipment failures before they happen. By integrating this data into PlanetTogether, production schedules can be adjusted automatically—reducing downtime and safeguarding customer commitments.

Automated Supplier Collaboration

Integrated systems can synchronize with supplier schedules, lead times, and capacities. With PlanetTogether providing multi-site planning across Oracle or SAP, procurement decisions align tightly with production needs, minimizing waste and overstocking.

Scenario Planning and Simulation

Using simulation tools built into APS platforms, managers can test multiple scenarios—disruptions, delays, demand spikes—and understand the impact on the supply chain. This ability to “see around the corner” is essential in high-stakes industrial production.

Real-Time Performance Monitoring

Smart dashboards and KPIs allow Supply Chain Managers to monitor performance against plan in real time. Integration with Aveva or Microsoft ensures the loop between planning and execution is continuous and closed.

Building Your Smart Supply Chain: Action Steps for Supply Chain Managers

Evaluate Current Maturity

Assess where your current systems fall short in visibility, planning accuracy, and agility.

Map Out Integration Opportunities

Identify integration points between your ERP system (e.g., Oracle, SAP) and APS platforms like PlanetTogether.

Invest in Data Infrastructure

Ensure data accuracy and connectivity across systems. Smart supply chains depend on clean, real-time data.

Implement in Phases

Start with high-impact areas such as demand forecasting, inventory control, or supplier coordination.

Train Teams for a Data-Driven Culture

Equip teams to interpret data, manage exceptions, and leverage predictive insights for daily decisions.

In industrial manufacturing, the speed of transformation is accelerating. Smart supply chains are no longer optional—they are the key to staying competitive in an era of disruption and complexity.

By combining the robust capabilities of PlanetTogether with leading ERP systems like SAP, Oracle, Microsoft, Kinaxis, or Aveva, Supply Chain Managers gain a powerful, intelligent infrastructure that empowers them to lead with foresight, agility, and confidence.

Now is the time to transition from fragmented, reactive operations to smart, synchronized supply chain systems—and unlock new levels of efficiency, resilience, and growth.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.

LEAVE A COMMENT