Smart Inventory Management Systems for Just-in-Time Replenishment

As an Operations Director, you understand the critical role inventory management plays in ensuring smooth operations and meeting customer demands. Traditional inventory management systems are no longer sufficient in today's fast-paced environment. To stay competitive, chemical manufacturing facilities must embrace smart inventory management systems that enable just-in-time replenishment.

In this blog, we'll look into the development of such systems and explore how integration between PlanetTogether and leading ERP, SCM, and MES systems can revolutionize inventory management in chemical manufacturing.

Smart Inventory Management in Chemical Manufacturing

Chemical manufacturing involves intricate processes, stringent regulations, and volatile market demands. Traditional inventory management methods often lead to overstocking, stockouts, and increased operational costs. Just-in-time (JIT) replenishment offers a solution by ensuring that materials are ordered and received precisely when needed, minimizing inventory holding costs while maximizing efficiency.

Key Challenges in Implementing JIT Replenishment Systems

While the benefits of JIT replenishment are clear, implementing such systems comes with its challenges, especially in the complex environment of chemical manufacturing:

Real-Time Visibility: Accurate real-time data is essential for JIT replenishment. Many chemical manufacturers struggle with disparate systems and siloed data, leading to inaccuracies and delays in inventory management.

Supply Chain Complexity: Chemical manufacturing supply chains are often complex, involving multiple suppliers, raw materials, and production processes. Coordinating these elements to ensure JIT replenishment requires seamless integration and communication across the supply chain.

Regulatory Compliance: Compliance with regulatory requirements adds another layer of complexity to inventory management. Ensuring that materials are sourced from approved suppliers and meeting quality standards is crucial for chemical manufacturers.

Forecasting Accuracy: JIT replenishment relies heavily on accurate demand forecasting. Fluctuating market demands and unforeseen events can make forecasting challenging, leading to either stockouts or excess inventory.

The Role of Smart Inventory Management Systems

Smart inventory management systems leverage advanced technologies such as artificial intelligence, machine learning, and IoT sensors to address the challenges mentioned above. These systems offer the following benefits:

Real-Time Data Integration: Integration between inventory management systems and ERP, SCM, and MES platforms allows for seamless data exchange in real-time. This ensures accurate inventory visibility across the supply chain, enabling proactive decision-making.

Predictive Analytics: Machine learning algorithms analyze historical data to predict future demand more accurately. By considering factors such as seasonality, market trends, and production schedules, predictive analytics minimize the risk of stockouts and overstocking.

Automated Ordering: Smart inventory management systems can automate the replenishment process based on predefined triggers and rules. This eliminates manual intervention, reduces human error, and streamlines the procurement process.

Supplier Collaboration: Collaborative platforms enable closer alignment between chemical manufacturers and their suppliers. Through shared visibility and communication channels, both parties can optimize inventory levels and respond promptly to changes in demand.

Integration with PlanetTogether and Leading ERP, SCM, and MES Systems

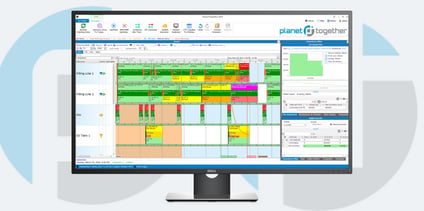

PlanetTogether is a leading advanced planning and scheduling (APS) software trusted by many chemical manufacturers worldwide. By integrating PlanetTogether with ERP, SCM, and MES systems such as SAP, Oracle, Microsoft, Kinaxis, and Aveva, chemical manufacturers can achieve a seamless flow of information across their operations.

SAP Integration: SAP is widely used in the chemical manufacturing industry for its robust ERP capabilities. Integrating PlanetTogether with SAP enables real-time synchronization of production schedules, inventory levels, and procurement activities. This integration ensures that JIT replenishment decisions are based on accurate data, optimizing inventory levels and minimizing costs.

Oracle Integration: Oracle's SCM solutions offer comprehensive supply chain management functionalities. By integrating PlanetTogether with Oracle SCM, chemical manufacturers can leverage advanced planning capabilities to optimize production schedules and inventory levels. This integration enables better coordination between production, procurement, and distribution processes, enhancing overall efficiency.

Microsoft Integration: Microsoft's Dynamics 365 suite provides ERP and SCM solutions tailored to the needs of chemical manufacturers. Integrating PlanetTogether with Microsoft Dynamics allows for seamless data exchange and collaboration across various departments. Chemical manufacturers can leverage Microsoft's cloud infrastructure and analytical tools to gain deeper insights into their inventory management processes, driving continuous improvement and innovation.

Kinaxis Integration: Kinaxis offers a cloud-based SCM platform known for its agility and flexibility. By integrating PlanetTogether with Kinaxis RapidResponse, chemical manufacturers can achieve end-to-end supply chain visibility and orchestration. This integration enables proactive decision-making based on real-time insights, helping manufacturers adapt quickly to changes in demand or supply.

Aveva Integration: Aveva's MES solutions are designed to optimize production operations and improve manufacturing efficiency. Integrating PlanetTogether with Aveva MES enables seamless coordination between production scheduling and execution. This integration ensures that JIT replenishment decisions align with production capacities and resource availability, minimizing disruptions and maximizing throughput.

The development of smart inventory management systems is crucial for chemical manufacturers seeking to achieve just-in-time replenishment and maintain a competitive edge. By leveraging advanced technologies and integrating with leading ERP, SCM, and MES systems such as PlanetTogether, SAP, Oracle, Microsoft, Kinaxis, and Aveva, chemical manufacturers can optimize inventory levels, reduce costs, and enhance operational efficiency.

Embracing smart inventory management is not just a choice but a necessity in today's rapidly evolving manufacturing landscape. As an Operations Director, investing in these technologies will position your facility for success in the years to come. Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.