Topics: Advanced Planning and Scheduling, manufacturing, PlanetTogether, production planning, Implementation, APS, SAP, Demand Forecasting, Demand planning, implementation speed, manufacturing technology

Successful demand planning within a manufacturing operation is a challenge many project managers struggle with. Demand planning calls for various attributes such as reliable consumer data to be able to forecast accurately.

Without accurate data, the whole system becomes unreliable and production is unsure of how much to produce - especially in swift demand changing circumstances. Therefore, implementing a demand planning system such as SAP demand planning can efficiently improve your manufacturing operation. SAP can be augmented further with advanced planning and scheduling system software (APS), allowing refinement at the macro and micro levels.

Without accurate data, the whole system becomes unreliable and production is unsure of how much to produce - especially in swift demand changing circumstances. Therefore, implementing a demand planning system such as SAP demand planning can efficiently improve your manufacturing operation. SAP can be augmented further with advanced planning and scheduling system software (APS), allowing refinement at the macro and micro levels.

Implementation of SAP demand planning is quick and simple, though, often not the be-all-end-all in terms of a final, best and total solution (see "Advanced Planning and Scheduling (APS) Integration of SAP Demand Planning" section below). Defining the most important attributes of your production facility and establishing the key figures that affect your demand is a first step in the process of implementation.  As these figures are considered, presenting actual and historical data into the system will allow for accurate forecasting and development of a plan for a varying demand. Other key factors in demand planning implementation include the following:

As these figures are considered, presenting actual and historical data into the system will allow for accurate forecasting and development of a plan for a varying demand. Other key factors in demand planning implementation include the following:

Thoroughly analyzing all of these key factors will allow for enhancement of your demand planning process and provide a simple integration of demand planning methods.

SAP demand planning has various benefits that can be extremely beneficial to manufacturing operations that are wanting to improve demand planning. Along with simple and quick implementation, various benefits include the following:

These benefits and capabilities will adequately improve your manufacturing operation and optimize your demand and production through data accuracy, system integration, and overall operational efficiency.

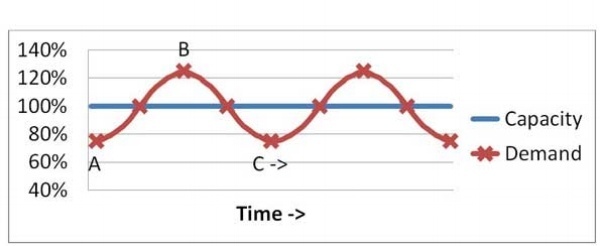

Advanced planning and scheduling (APS) software is a robust extension of an ERP system such as SAP, and allows for a far more deeper insight into demand planning. Through presented up-to-the-minute data, an integrated ERP/APS system can accurately respond to forecasted demand. Together, the capabilities and benefits of an integrated solution capitalizes on the sum of parts and can greatly improve response to an ever-shifting demand.

Topics: Advanced Planning and Scheduling, manufacturing, PlanetTogether, production planning, Implementation, APS, SAP, Demand Forecasting, Demand planning, implementation speed, manufacturing technology

0 Comments

No video selected

Select a video type in the sidebar.

LEAVE A COMMENT