Rising Supply Chain Costs in Food and Beverage Manufacturing: How Production Schedulers Can Overcome the Challenge with Smart Integration

In the dynamic world of food and beverage (F&B) manufacturing, production schedulers find themselves on the front lines of a growing crisis—rising costs driven by ongoing supply chain disruptions. From raw material volatility and unpredictable transportation delays to global labor shortages and fluctuating demand patterns, the pressure to deliver efficiently and economically has never been greater.

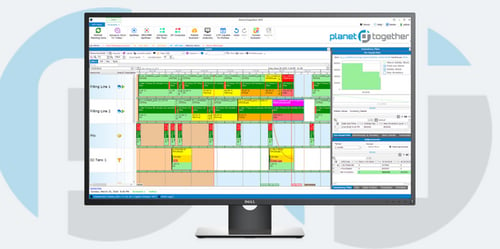

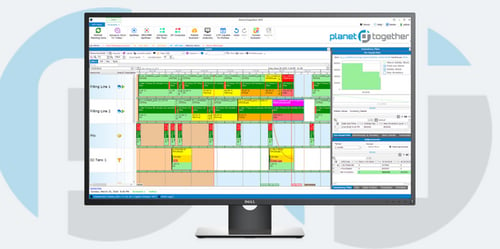

As the complexity of supply networks deepens, traditional scheduling approaches often fail to keep up. But there’s good news: integrated Advanced Planning and Scheduling (APS) systems like PlanetTogether, when connected to leading ERP platforms such as SAP, Oracle, Microsoft, Kinaxis, or Aveva, are empowering production schedulers with real-time visibility and smart automation to counter rising supply chain costs.

This blog explores how production schedulers in F&B manufacturing can tackle cost pressures through enhanced planning, smart integration, and agile response mechanisms.

Understanding the Supply Chain Cost Surge

The recent surge in supply chain costs is rooted in several converging trends:

Raw Material Inflation: Prices for key ingredients—wheat, corn, dairy, packaging materials—have been volatile due to climate disruptions and geopolitical instability.

Logistics Disruptions: Port congestion, fuel cost increases, and a shortage of drivers have severely impacted delivery timelines and costs.

Labor Market Tightness: Labor shortages are leading to inconsistent production cycles and higher wages across the supply chain.

Consumer Demand Shifts: Sudden spikes in demand for healthier, functional, or sustainable products are challenging F&B manufacturers to remain responsive.

These factors compound daily scheduling difficulties, turning every production decision into a cost-sensitive choice.

The Central Role of the Production Scheduler

The production scheduler is no longer just coordinating machine time and labor—today, they must balance cost constraints, ingredient availability, shelf-life compliance, and customer expectations. This expanded role requires fast access to accurate data, cross-functional coordination, and flexible tools.

Key responsibilities under pressure:

Sequencing production for minimal waste and downtime

Responding to last-minute order changes or delays

Avoiding overproduction or spoilage of perishable goods

Coordinating upstream (procurement) and downstream (distribution) activities

Without real-time integration and advanced planning tools, schedulers are forced to rely on spreadsheets and intuition, which can inadvertently increase costs.

Enter Advanced Planning & Scheduling: A Cost-Containment Enabler

PlanetTogether APS, especially when integrated with enterprise systems like SAP, Oracle, Microsoft Dynamics, Kinaxis, or Aveva, gives production schedulers a powerful suite of capabilities to streamline decisions and reduce costs:

Real-Time Visibility into Material and Resource Constraints

By integrating with ERP systems, PlanetTogether pulls in real-time inventory, demand forecasts, supplier lead times, and production capacity. This helps schedulers avoid costly surprises and allows for data-driven planning.

Dynamic Rescheduling Based on Disruptions

When a shipment is delayed or a line goes down, PlanetTogether allows immediate recalculation of optimal schedules. Schedulers can re-prioritize jobs, shift workloads, and reduce idle time—cutting both direct and indirect costs.

Optimized Lot Sizing and Batch Sequencing

Minimizing changeovers and aligning production with optimal lot sizes can significantly reduce material waste, especially in processes with strict hygiene requirements. Integrated scheduling tools ensure that these efficiencies are applied at scale.

Scenario Planning for Cost Forecasting

PlanetTogether’s what-if simulation capabilities enable schedulers to test different production plans and understand their cost implications. For example, producing ahead of an anticipated price hike in packaging materials might offer a strategic advantage.

Labor and Energy Efficiency

Through synchronized planning with HR systems or utility monitoring tools via ERP platforms, production can be scheduled to align with labor availability and off-peak energy pricing, helping reduce overhead costs.

Strategic Advantages of ERP-APS Integration

Whether you're operating on SAP’s S/4HANA, Oracle Cloud SCM, Microsoft Dynamics 365, Kinaxis RapidResponse, or Aveva’s operations platform, integration with PlanetTogether APS brings tangible cost-control benefits:

| ERP System |

APS Integration Benefits |

| SAP |

Enhanced MRP accuracy, real-time BOM/recipe updates, and better financial alignment |

| Oracle |

Cross-functional data sharing, dynamic cost rollups, and responsive demand planning |

| Microsoft |

Streamlined workflows, intuitive dashboards, and tight integration with manufacturing execution |

| Kinaxis |

Agile scenario-based scheduling aligned with supply chain risk profiles |

| Aveva |

Seamless integration of plant operations and energy efficiency into planning decisions |

Each integration empowers schedulers with a holistic view of production economics, making it easier to identify cost leaks and act proactively.

The rise in supply chain costs isn’t a temporary problem—it’s the new normal for food and beverage manufacturers. But with integrated scheduling solutions like PlanetTogether APS, production schedulers are better equipped than ever to navigate this volatility with agility and precision.

By aligning real-time production data with enterprise systems like SAP, Oracle, Microsoft, Kinaxis, or Aveva, schedulers can make smarter decisions that reduce waste, optimize resources, and protect profitability.

In a world where every dollar counts, the production scheduler—empowered by the right tools—becomes a strategic asset in the battle against rising supply chain costs.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.

LEAVE A COMMENT