Harnessing Predictive Analytics for Scheduling Efficiency

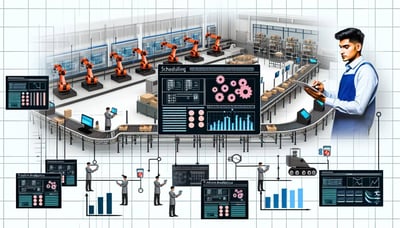

Supply chain managers face an increasingly complex challenge: optimizing production schedules to meet demand while minimizing costs and maximizing efficiency. Traditional scheduling methods often fall short in adapting to the dynamic nature of modern supply chains. However, with the advent of predictive analytics, there's a new frontier of opportunity emerging, promising to revolutionize supply chain scheduling.

In this blog, we look into the transformative power of predictive analytics and how integrating solutions like PlanetTogether with leading ERP, SCM, and MES systems can drive unprecedented efficiency gains.

Predictive Analytics

At its core, predictive analytics involves leveraging historical data, statistical algorithms, and machine learning techniques to forecast future trends and behaviors. In the context of supply chain scheduling, predictive analytics enables managers to anticipate demand fluctuations, optimize production schedules, and proactively mitigate potential disruptions.

The Role of PlanetTogether

PlanetTogether stands at the forefront of advanced planning and scheduling software, offering robust capabilities to streamline production scheduling processes. By harnessing predictive analytics, PlanetTogether empowers supply chain managers to make data-driven decisions, optimize resource allocation, and enhance overall operational efficiency.

Integration with ERP, SCM, and MES Systems

The true power of predictive analytics in supply chain scheduling lies in its seamless integration with existing ERP, SCM, and MES systems. Whether it's SAP, Oracle, Microsoft, Kinaxis, Aveva, or other leading platforms, the synergy between predictive analytics and these systems unlocks a new level of visibility, agility, and responsiveness across the supply chain.

Benefits of Integration:

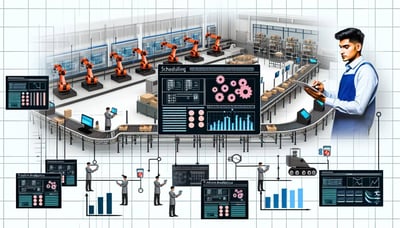

Enhanced Forecasting Accuracy: By integrating predictive analytics with ERP systems, supply chain managers gain access to real-time data insights, enabling more accurate demand forecasting and resource planning.

Dynamic Production Scheduling: Leveraging predictive analytics within MES systems allows for dynamic adjustments to production schedules based on evolving demand patterns, resource availability, and operational constraints.

Proactive Risk Management: With the integration of predictive analytics into SCM systems, supply chain managers can identify potential disruptions in advance and take proactive measures to mitigate risks, such as inventory shortages or supplier delays.

Optimal Resource Utilization: By synchronizing PlanetTogether with ERP, SCM, and MES systems, supply chain managers can optimize resource utilization, minimize idle time, and maximize production efficiency across the entire value chain.

Predictive analytics represents a paradigm shift in supply chain management, offering unparalleled insights and agility in scheduling operations. By integrating solutions like PlanetTogether with leading ERP, SCM, and MES systems, supply chain managers can unlock the full potential of predictive analytics, driving efficiency, resilience, and competitiveness in industrial manufacturing.

Embracing this transformative technology is not just a choice but a strategic imperative in navigating the complexities of the modern supply chain landscape. Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.

LEAVE A COMMENT