Global Quality Management System Logistics

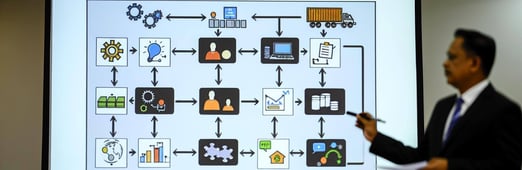

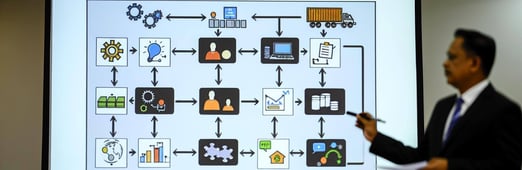

The efficacy of supply chain management directly impacts the quality and efficiency of operations in chemical manufacturing. With globalization expanding market reach and competition, ensuring a seamless logistics process is paramount. Today, Supply Chain Managers grapple with the challenge of integrating diverse systems to optimize the Global Quality Management System (GQMS) logistics.

In this blog, we explore how the integration between PlanetTogether and top-tier ERP, SCM, and MES systems transforms GQMS logistics, enhancing efficiency, quality, and competitiveness.

What is Global Quality Management System Logistics?

GQMS logistics is the backbone of chemical manufacturing operations, encompassing the flow of materials, information, and resources from suppliers to customers while ensuring compliance with stringent quality standards. Achieving seamless GQMS logistics demands real-time visibility, efficient planning, and robust execution across the supply chain.

Challenges in GQMS Logistics:

Complex Supply Networks: Chemical manufacturing involves intricate supply networks spanning multiple geographies, suppliers, and partners, amplifying the complexity of logistics management.

Regulatory Compliance: Compliance with global regulatory standards such as REACH and GHS requires meticulous documentation, traceability, and quality control throughout the supply chain.

Demand Volatility: Fluctuating demand patterns necessitate agile planning and responsive logistics to prevent stockouts, minimize excess inventory, and optimize resource utilization.

Siloed Systems: Disparate ERP, SCM, and MES systems operating in isolation hinder data visibility, collaboration, and decision-making, leading to inefficiencies and errors.

The Role of Integration in GQMS Logistics

Integration acts as a catalyst for streamlining GQMS logistics by bridging the gap between disparate systems, enabling seamless data exchange, and fostering collaboration across the supply chain ecosystem. Among the leading integration solutions, the synergy between PlanetTogether and prominent ERP, SCM, and MES systems emerges as a game-changer for Supply Chain Managers.

Integration Between PlanetTogether and Leading Systems

SAP: The integration between PlanetTogether and SAP ERP empowers Supply Chain Managers with end-to-end visibility, robust planning capabilities, and synchronized execution. Seamless data synchronization ensures accurate demand forecasting, inventory optimization, and production scheduling, thereby enhancing GQMS logistics efficiency.

Oracle: Leveraging the integration between PlanetTogether and Oracle SCM Cloud, Supply Chain Managers gain real-time insights into inventory levels, demand fluctuations, and supplier performance. Automated planning and scheduling functionalities enable proactive risk management and responsive logistics, driving superior quality and customer satisfaction.

Microsoft Dynamics 365: The integration between PlanetTogether and Microsoft Dynamics 365 Supply Chain Management optimizes resource utilization, minimizes lead times, and enhances production agility. Unified data access and analytics facilitate data-driven decision-making, enabling Supply Chain Managers to adapt to evolving market dynamics and regulatory requirements seamlessly.

Kinaxis: With the integration between PlanetTogether and Kinaxis RapidResponse, Supply Chain Managers harness advanced analytics, scenario modeling, and collaborative planning capabilities. Real-time synchronization of demand, supply, and capacity data enables agile decision-making, enabling organizations to proactively mitigate risks and capitalize on emerging opportunities.

Aveva: The integration between PlanetTogether and Aveva Manufacturing Execution System (MES) enhances shop floor visibility, process efficiency, and quality control. Seamless data exchange between planning and execution systems enables closed-loop feedback, ensuring alignment between production schedules and quality standards.

Benefits of Integration for GQMS Logistics

Enhanced Visibility: Integration provides Supply Chain Managers with real-time insights into inventory levels, production schedules, and quality metrics, enabling proactive decision-making and risk management.

Improved Efficiency: Automated planning, scheduling, and execution streamline GQMS logistics, minimizing lead times, reducing costs, and optimizing resource utilization.

Compliance Assurance: Seamless data exchange and traceability ensure compliance with regulatory standards, quality certifications, and customer requirements, mitigating the risk of non-compliance penalties and reputational damage.

Agile Responsiveness: Integration enables Supply Chain Managers to respond swiftly to demand fluctuations, supply disruptions, and quality issues, fostering customer satisfaction and competitive advantage.

Continuous Improvement: Data-driven analytics and performance metrics facilitate continuous optimization of GQMS logistics processes, driving operational excellence and strategic alignment.

In the era of digital transformation, integration between PlanetTogether and leading ERP, SCM, and MES systems revolutionizes GQMS logistics in chemical manufacturing facilities. By bridging the gap between disparate systems, Supply Chain Managers unlock unprecedented visibility, efficiency, and agility across the supply chain, ensuring seamless compliance with quality standards and customer expectations.

Embracing integration is not merely a technological upgrade but a strategic imperative for organizations seeking to thrive in an increasingly complex and competitive landscape. Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.

LEAVE A COMMENT