Reimagining Global Supply Chains

In recent years, global supply chains have experienced unprecedented disruption. From the COVID-19 pandemic to geopolitical tensions and economic uncertainties, these challenges have led to a critical re-examination of traditional supply chain models. For Supply Chain Managers in industrial manufacturing, the stakes are particularly high. With industrial facilities often relying on a complex network of suppliers, manufacturers, and distributors spread across the globe, the need for flexibility, resilience, and efficiency has never been more apparent.

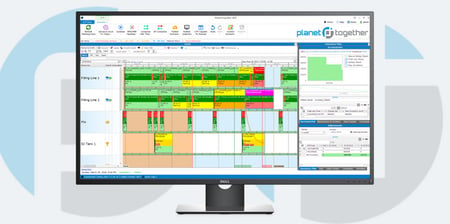

Reimagining global supply chains isn't just about survival—it's about thriving in a new era of interconnectedness and innovation. At the forefront of this transformation is the integration of advanced planning and scheduling software like PlanetTogether with enterprise resource planning (ERP) systems such as SAP, Oracle, Microsoft Dynamics, Kinaxis, and Aveva. This integration offers new avenues for industrial manufacturers to optimize operations, manage risks, and navigate the evolving global landscape.

The Current State of Global Supply Chains

Before looking into the solutions, it’s important to understand the current state of global supply chains in industrial manufacturing. The sector has been particularly vulnerable to supply chain shocks due to the heavy reliance on raw materials, complex production processes, and a global network of suppliers and customers.

Some of the most pressing challenges include:

Raw Material Shortages: Scarcity of critical materials like metals and semiconductors has caused delays across industries, leading to production slowdowns.

Geopolitical Instabilities: Tariffs, trade wars, and regional conflicts have led to increased costs and uncertainty in sourcing.

Transportation and Logistics Issues: From container shortages to port congestion, logistics bottlenecks have created delays and increased shipping costs.

Shifts in Consumer Demand: As consumer preferences rapidly change, supply chains must become more agile and responsive.

These factors create a landscape where traditional, linear supply chain models are no longer sufficient. The answer lies in building a more dynamic, real-time, and data-driven approach—one that leverages the power of advanced technology to improve decision-making and operational efficiency.

![]()

The Role of Integrated Planning in Reimagining Supply Chains

One of the key elements of reimagining global supply chains is the integration of advanced planning systems with robust ERP platforms. This combination allows for a more holistic view of the entire supply chain, from raw material procurement to final product delivery.

Here’s where PlanetTogether’s Advanced Planning and Scheduling (APS) software comes into play. When integrated with leading ERP systems like SAP, Oracle, Microsoft Dynamics, Kinaxis, or Aveva, it creates a powerful toolset that allows supply chain managers to:

Optimize Production Scheduling: Aligning production schedules with real-time demand and supply data reduces inefficiencies and waste. This is particularly important in industries where downtime can be costly and difficult to recover from.

Improve Demand Forecasting: Accurate demand forecasting is critical for managing inventory levels, avoiding stockouts, and reducing excess inventory. The integration between PlanetTogether and ERP systems helps forecast demand with greater precision, enabling better alignment of supply with fluctuating market needs.

Enhance Supply Chain Visibility: Integrated systems provide a real-time view of supply chain operations, allowing for quicker identification of bottlenecks or potential disruptions. This visibility enables proactive problem-solving rather than reactive management.

Enhancing Agility and Resilience Through Integration

A key theme in reimagining global supply chains is the shift from efficiency to resilience. Traditionally, supply chains have been optimized for efficiency, often at the expense of flexibility and risk mitigation. However, in a world where disruptions are increasingly common, supply chains need to be agile and resilient.

Here’s how the integration of PlanetTogether with systems like Oracle or Kinaxis can help:

Scenario Planning and What-If Analysis: PlanetTogether’s ability to model different production scenarios allows Supply Chain Managers to anticipate potential disruptions and develop contingency plans. For example, if a key supplier is unable to deliver on time, PlanetTogether can automatically reroute production to alternate suppliers or adjust the production schedule to minimize downtime.

Buffer Stock Management: By leveraging real-time data from an integrated system, managers can optimize buffer stocks to account for supply chain uncertainties without overstocking and tying up working capital.

Risk Management: Integrating PlanetTogether with advanced ERP systems allows for the incorporation of risk metrics into the planning process. For instance, when geopolitical risks threaten a particular supply route, the system can suggest alternate suppliers or shipping methods that mitigate risk.

This integration transforms the supply chain from a linear, static process to a dynamic, adaptable network that can respond quickly to changes in demand, supply, and external conditions.

Sustainable and Ethical Supply Chains: The Next Frontier

As global awareness of environmental and ethical issues grows, sustainability has become a core consideration for industrial manufacturers. Reimagining supply chains is not just about improving efficiency or reducing costs—it's also about making supply chains more sustainable and socially responsible.

The integration of PlanetTogether with systems like Aveva, known for its focus on sustainability and energy management, can play a pivotal role in this transformation. For instance, by integrating production data with energy usage data, Supply Chain Managers can optimize production schedules to minimize energy consumption and reduce carbon emissions.

Other sustainability benefits include:

Reducing Waste: Advanced planning systems can optimize production runs to reduce excess inventory and minimize waste.

Ethical Sourcing: Integrated systems allow for better tracking of supplier certifications and compliance with ethical sourcing standards.

Energy-Efficient Operations: By aligning production schedules with energy-efficient timeframes (such as off-peak energy hours), manufacturers can significantly reduce their carbon footprint.

These advancements not only help companies meet regulatory requirements but also appeal to environmentally conscious consumers and investors.

A New Era for Supply Chain Management in Industrial Manufacturing

Reimagining global supply chains is no longer a distant vision—it’s a necessity. For Supply Chain Managers in industrial manufacturing, the challenges are clear: disruptions, inefficiencies, and increasing demands for sustainability. However, with the integration of advanced planning tools like PlanetTogether and powerful ERP systems like SAP, Oracle, Microsoft Dynamics, Kinaxis, or Aveva, these challenges can be transformed into opportunities.

This integration allows for enhanced visibility, improved decision-making, and the agility needed to thrive in an ever-changing global landscape. By embracing these technologies, industrial manufacturers can not only protect their supply chains from future disruptions but also create a more sustainable, efficient, and resilient supply chain for years to come.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.

The future of supply chain management is here—are you ready to embrace it?

Topics: Industrial Manufacturing, PlanetTogether Software, Integrating PlanetTogether, Improved Decision Making, Scenario Planning and What-if Analysis, Proactive Risk Management, Enhanced Visibility, Improve Demand Forecasting Accuracy, Optimize Production Scheduling, Buffer Stock Management

LEAVE A COMMENT