Refreshing Sustainability Strategies for Chemical Manufacturing

Sustainability is no longer a buzzword in the chemical manufacturing industry; it is a cornerstone of strategic operations. Operations Directors face increasing pressure to meet environmental, social, and governance (ESG) goals while maintaining efficiency, profitability, and compliance. As the industry evolves, integrating advanced tools like PlanetTogether with enterprise systems such as SAP, Oracle, Microsoft, Kinaxis, or Aveva can breathe new life into sustainability initiatives.

In this blog, we will explore how leveraging integrated systems enables chemical manufacturers to refresh their sustainability strategies, optimize resource utilization, reduce emissions, and achieve long-term competitive advantage.

The Need for Sustainability in Chemical Manufacturing

Chemical manufacturing is among the most resource-intensive and environmentally impactful industries. High energy consumption, greenhouse gas emissions, and the use of hazardous materials present significant sustainability challenges. Stakeholders, including regulatory bodies, customers, and investors, demand transparency and tangible progress toward sustainability.

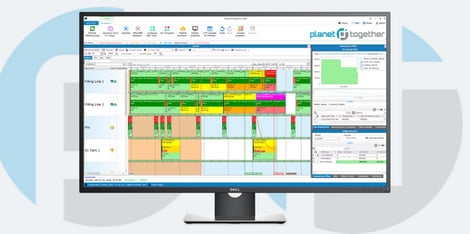

However, achieving these goals requires more than superficial changes. It calls for operational excellence rooted in data-driven decision-making and robust process integration. This is where tools like PlanetTogether, when integrated with enterprise resource planning (ERP) and advanced supply chain platforms, play a pivotal role.

Key Components of a Refreshed Sustainability Strategy

1. Resource Efficiency and Waste Reduction

Efficient use of resources minimizes waste and reduces costs, aligning with sustainability objectives. By integrating PlanetTogether with enterprise systems like SAP or Oracle, manufacturers can:

Optimize Production Scheduling: Synchronize production schedules with raw material availability to minimize overproduction and waste.

Monitor Resource Consumption: Track energy, water, and material usage in real-time to identify inefficiencies.

Implement Circular Practices: Coordinate recycling and reusability efforts across production lines.

For instance, PlanetTogether’s scheduling software can analyze production scenarios to ensure optimal utilization of by-products, reducing landfill waste and maximizing value from every resource.

2. Emission Monitoring and Reduction

Reducing carbon emissions is a critical metric for ESG compliance. Integration between PlanetTogether and platforms like Aveva’s Unified Operations Center provides:

Carbon Footprint Tracking: Real-time monitoring of emissions across production processes.

Scenario Planning: Evaluate alternative production scenarios to identify low-emission options.

Compliance Reporting: Automate the documentation required for regulatory adherence.

With these capabilities, operations directors can make informed decisions that reduce emissions without compromising output.

3. Energy Optimization

Energy consumption accounts for a significant portion of operating costs and environmental impact in chemical manufacturing. Integrating PlanetTogether with Microsoft Dynamics 365 or SAP enables:

Load Balancing: Distribute energy usage across production lines to avoid peak-hour surcharges.

Predictive Maintenance: Prevent energy losses by identifying equipment inefficiencies before failures occur.

Renewable Integration: Schedule production activities to align with renewable energy availability.

These measures not only cut costs but also contribute to achieving net-zero energy goals.

The Role of Digital Integration in Sustainability

Digital integration bridges the gap between sustainability goals and operational realities. Here’s how integrating PlanetTogether with systems like Kinaxis or Oracle transforms sustainability strategies:

Data Centralization

A unified data ecosystem ensures seamless communication across departments. For example:

Kinaxis’ RapidResponse platform integrates with PlanetTogether to provide end-to-end visibility of supply chain operations.

This visibility helps align procurement, production, and logistics with sustainability objectives.

Advanced Analytics

Integrated systems enable advanced analytics, offering predictive insights and actionable intelligence. Operations Directors can:

Identify trends in resource usage and emissions.

Simulate various production scenarios to evaluate their sustainability impact.

Use AI-driven recommendations for continuous improvement.

Agility and Resilience

The chemical manufacturing industry often faces supply chain disruptions, regulatory changes, and market volatility. Integrated platforms enhance agility by:

Facilitating rapid adjustments to production schedules.

Ensuring compliance with evolving environmental regulations.

Mitigating risks through real-time monitoring and predictive modeling.

Overcoming Implementation Challenges

While the benefits are clear, integrating PlanetTogether with platforms like SAP, Oracle, or Aveva requires careful planning. Here are some best practices:

Stakeholder Alignment

Ensure all stakeholders understand the value of integration. Collaborate with IT, production, and sustainability teams to define objectives and KPIs.

Phased Implementation

Start with a pilot project to validate the integration’s effectiveness. Gradually scale up based on insights and feedback.

Training and Support

Invest in training programs to ensure users can leverage the full potential of integrated systems. Continuous support is crucial for long-term success.

Refreshing sustainability strategies in chemical manufacturing requires a holistic approach that combines operational efficiency, data-driven insights, and advanced integration. By leveraging PlanetTogether with ERP Systems like SAP, Oracle, Microsoft, Kinaxis, or Aveva, Operations Directors can drive meaningful progress toward ESG goals while enhancing profitability and resilience.

In the race toward a sustainable future, integrated digital solutions are not just an advantage—they are a necessity. Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.

Topics: Advanced Analytics, PlanetTogether Software, Integrating PlanetTogether, Optimize Energy Usage, Data Centralization, Chemical Manufacturing, Minimize Waste Generation, Enhance Reporting

LEAVE A COMMENT