Rebalancing Inventories in Pharmaceutical Manufacturing to Greater Control with Integrated APS

For supply chain managers in pharmaceutical manufacturing, maintaining the right inventory levels is a tightrope walk. Overstocking ties up capital and risks product expiration, while understocking can delay production and impact patient outcomes. Amid increasingly complex global supply chains, volatile demand, and stringent regulatory requirements, rebalancing inventories has become both more critical and more complex.

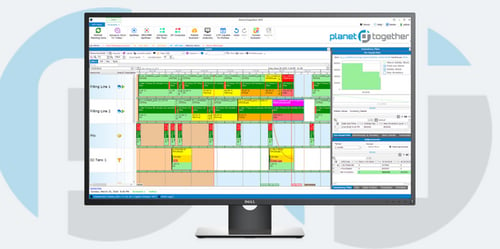

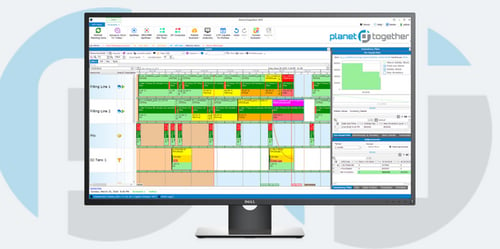

To meet this challenge head-on, forward-thinking pharma manufacturers are turning to Advanced Planning and Scheduling (APS) solutions like PlanetTogether, especially when integrated with enterprise platforms such as SAP, Oracle, Microsoft, Kinaxis, or Aveva. These integrated systems allow for more accurate demand forecasting, real-time inventory visibility, and agile planning strategies that keep operations lean and compliant.

The Pharmaceutical Inventory Dilemma

Pharmaceutical inventory management comes with a unique set of challenges:

Product shelf-life constraints: Many pharmaceutical products have limited expiration dates, leading to waste if not used in time.

Stringent compliance standards: Regulatory requirements mandate lot traceability, quality control, and accurate documentation.

Complex product portfolios: The surge in personalized medicine and biotech innovations has led to more diverse SKUs and batch sizes.

Global dependencies: APIs and raw materials are often sourced globally, making the supply chain more susceptible to delays and disruptions.

With so many moving parts, traditional planning methods and siloed systems are no longer sufficient.

The Role of APS in Rebalancing Inventories

Rebalancing inventories isn’t just about reducing stock levels—it’s about aligning inventory with real demand, production schedules, and market availability. This is where Advanced Planning and Scheduling (APS) systems shine.

PlanetTogether APS allows pharmaceutical supply chain managers to:

Simulate and optimize production schedules in real time.

Balance raw material and finished goods inventories based on actual demand signals.

Identify bottlenecks and adjust production capacity accordingly.

Coordinate closely with procurement and warehousing to reduce stockouts and overages.

However, the real power of APS is unlocked when it’s integrated with enterprise platforms like SAP, Oracle, Microsoft Dynamics, Kinaxis, or Aveva—systems already embedded in the DNA of pharmaceutical operations.

Integration in Action: APS + SAP, Oracle, Microsoft, Kinaxis, or Aveva

Real-Time Data Synchronization

Integrating PlanetTogether APS with platforms like SAP or Oracle ensures real-time data flow between planning, production, and inventory. When an update occurs in the ERP—say, a supplier delay or an urgent order—the APS system immediately recalibrates schedules and inventory needs.

This synchronization empowers supply chain managers to:

React to disruptions faster.

Avoid costly last-minute procurement.

Replan batches dynamically without manual rework.

End-to-End Visibility

Microsoft Dynamics and Kinaxis are known for robust supply chain visibility features. When PlanetTogether APS integrates with these platforms, it provides a centralized view of material availability, batch readiness, and capacity constraints across sites.

This level of visibility allows you to:

Identify where inventories can be reallocated.

Determine optimal production locations for certain SKUs.

Align warehouse replenishment with batch release timing.

Scenario-Based Planning and Optimization

Aveva’s industrial platforms emphasize digital twins and simulation. When combined with APS, they enable scenario modeling that’s crucial for inventory rebalancing.

You can simulate:

The impact of raw material shortages on future inventory levels.

The effect of a spike in demand for a specific drug class.

Shelf-life expiration risks under different storage and production timelines.

This proactive approach allows pharmaceutical supply chain teams to maintain resilience and agility.

Benefits for the Supply Chain Manager

Improved Inventory Turnover

Avoids excess holding costs while maintaining critical safety stock.

Reduced Waste

Better expiration management through optimized scheduling and batch tracking.

Enhanced Compliance

Improved traceability and documentation aligned with FDA, EMA, and other regulatory standards.

Faster Response Times

Agile planning in response to disruptions, recalls, or spikes in demand.

Streamlined Communication

Alignment across production, procurement, warehousing, and finance.

Building a Rebalancing Strategy with Integrated Tools

For supply chain managers ready to adopt a more proactive, data-driven approach to inventory management, here are key strategic steps:

Audit and Categorize Inventories

Use ABC analysis to understand which inventories are critical and which can be optimized.

Define Safety Stock Levels

Establish dynamic safety stock thresholds that adapt based on consumption patterns and supply variability.

Integrate APS with ERP

Ensure that PlanetTogether is connected with your SAP, Oracle, Microsoft, Kinaxis, or Aveva environment for real-time insights.

Leverage Forecast Accuracy

Improve demand forecasting using historical data and predictive analytics to align production with true demand.

Adopt Continuous Planning Cycles

Replace static monthly planning with rolling forecasts and weekly planning cycles driven by real-time data.

In pharmaceutical manufacturing, inventory is more than just a cost center—it’s a vital component of product availability, compliance, and patient care. Rebalancing inventories is no longer a once-a-quarter exercise; it’s a dynamic, continuous process.

By integrating PlanetTogether APS with SAP, Oracle, Microsoft Dynamics, Kinaxis, or Aveva, supply chain managers can harness the real-time data, analytics, and agility needed to drive smarter, more sustainable inventory decisions.

In a world where drug availability can be the difference between life and death, that kind of control isn’t just a competitive advantage—it’s a responsibility.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.

LEAVE A COMMENT