Real-Time Insights: Revolutionizing Supply Chain Management

Rapid and accurate decision-making is no longer a competitive advantage but a necessity in industrial manufacturing. Supply chain managers face unprecedented challenges in coordinating complex, global supply networks, balancing inventory, managing lead times, and addressing shifts in demand.

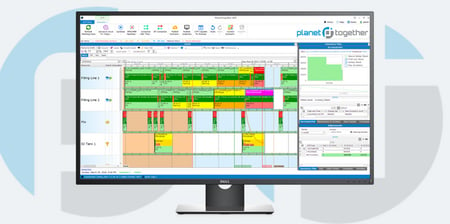

Integrating advanced planning and scheduling (APS) solutions like PlanetTogether with enterprise resource planning (ERP) systems such as SAP, Oracle, Microsoft, Kinaxis, or Aveva empowers manufacturing facilities with real-time insights, ultimately driving efficiencies and optimizing production across the supply chain.

Here’s how this powerful combination can revolutionize supply chain management in industrial manufacturing, ensuring that data-driven, responsive, and agile processes become the norm.

Real-Time Data in Industrial Manufacturing

Industrial manufacturing environments thrive on precision and timing, where small delays can lead to ripple effects that impact costs, resource utilization, and customer satisfaction. Traditional ERP systems are excellent for managing day-to-day operations, from financials and inventory to HR and procurement. However, they are often limited in their capability to support granular, real-time production planning and scheduling—critical for managing today’s fast-paced supply chains.

Incorporating a specialized APS solution like PlanetTogether bridges this gap by delivering real-time, actionable insights that integrate seamlessly with ERP systems. This integration gives supply chain managers a holistic view of the production landscape, enabling proactive decision-making and agile adjustments in response to ever-changing variables.

Benefits of Integrating PlanetTogether with ERP Systems for Real-Time Insights

Enhanced Visibility Across the Supply Chain

Integrating PlanetTogether with ERP systems like SAP, Oracle, or Microsoft offers comprehensive visibility across every step of the supply chain. With a unified view of production data, inventory levels, supplier schedules, and order statuses, supply chain managers can make informed decisions that maximize throughput and reduce lead times. Real-time insights allow for quick identification of bottlenecks, helping to anticipate and resolve production issues before they escalate.

Enhanced visibility also extends to suppliers and logistics partners, providing up-to-the-minute information on shipments, delays, and material availability. When every stakeholder has access to the same real-time data, alignment improves, and so does the overall agility of the supply chain.

Improved Demand Planning and Forecasting Accuracy

Demand planning in industrial manufacturing often relies on historical data and sales forecasts, but these methods can be limiting in a volatile market. Real-time integration between PlanetTogether and an ERP like Kinaxis or Aveva enhances demand forecasting accuracy by considering real-time production capacity, inventory levels, and actual demand trends. PlanetTogether’s APS capabilities adjust schedules on the fly based on real-time data, making it easier to align production with demand fluctuations.

Through this integration, supply chain managers can forecast more accurately, reducing the risk of stockouts or excess inventory. By tracking and responding to market trends in real time, manufacturers can also capture new opportunities and optimize production resources accordingly.

Streamlined Production Planning and Scheduling

Effective production planning and scheduling is the backbone of any industrial manufacturing operation. With real-time integration between PlanetTogether and ERP systems, scheduling becomes dynamic and responsive. PlanetTogether’s algorithm-based scheduling can process vast amounts of data to optimize resource allocation, sequencing, and lead times.

For example, if an ERP system detects a shortage of raw materials, PlanetTogether can adjust the production schedule instantly, reallocating resources to minimize downtime and ensure continuity. This responsiveness ensures that production remains on track even in the face of unexpected disruptions, enabling supply chain managers to optimize operational efficiency.

Enhanced Collaboration and Reduced Silos

One of the most significant challenges in large industrial manufacturing organizations is the existence of data silos, where different departments or teams operate in isolation, each with their own datasets and systems. Integrating PlanetTogether with an ERP like Microsoft Dynamics or Oracle helps to break down these silos, creating a centralized hub of data that can be accessed by everyone from production teams to logistics and sales.

The integration fosters a culture of collaboration, as all stakeholders work from the same set of real-time data, making cross-functional communication smoother. This transparency ensures that everyone in the supply chain can respond in unison to changes, reducing delays, miscommunication, and inefficiencies.

Real-Time Inventory Management and Optimization

In industrial manufacturing, inventory management is crucial for maintaining a balanced and cost-effective supply chain. Integrating PlanetTogether with an ERP system provides real-time insights into inventory levels across all facilities, enabling just-in-time inventory management. This real-time data allows supply chain managers to monitor stock levels, reorder points, and safety stocks dynamically.

This integration also facilitates predictive inventory management, where AI-driven analytics from PlanetTogether can forecast inventory needs based on production schedules and historical demand. By optimizing inventory levels, manufacturers can avoid costly overstock situations or production halts due to stockouts.

Accelerated Response to Disruptions

Disruptions are a fact of life in supply chain management, whether they stem from supply shortages, machine breakdowns, or logistical delays. Real-time data integration with PlanetTogether enables immediate response capabilities, allowing supply chain managers to identify disruptions as they occur and enact contingency plans swiftly.

When integrated with an ERP like SAP or Kinaxis, PlanetTogether can automatically adjust production schedules based on available resources, redirect shipments, or source alternative suppliers—all in real time. This agility minimizes the impact of disruptions, keeping production on track and reducing delays for customers.

Implementing Real-Time Integration: Best Practices

To maximize the benefits of integrating PlanetTogether with an ERP system, consider these best practices for implementation:

a) Data Standardization and Clean-Up

Real-time data integration relies on high-quality data. Before integrating PlanetTogether with an ERP, ensure that data is standardized, accurate, and up to date. This may involve cleansing existing datasets and establishing data governance protocols to maintain consistency across systems.

b) Define Clear KPIs for Monitoring

Identify the key performance indicators (KPIs) that are most critical to your supply chain operations. Common KPIs include on-time delivery rate, lead time, production efficiency, and inventory turnover. Setting clear KPIs helps track the effectiveness of the integration, measure improvements, and justify the investment to stakeholders.

c) Invest in Training and Change Management

A successful integration requires buy-in from all levels of the organization. Provide training on the new system to ensure all team members can leverage real-time insights effectively. Additionally, implement a change management plan to address potential resistance and help staff understand the value of integrating PlanetTogether with ERP systems.

d) Continuous Monitoring and Optimization

The supply chain is constantly evolving, and so should your integration. Regularly monitor the integration to identify any issues or opportunities for optimization. Updates to either PlanetTogether or your ERP system may impact functionality, so keeping both systems in sync is essential for maximizing real-time insights.

The integration of PlanetTogether with ERP systems like SAP, Oracle, Microsoft, Kinaxis, or Aveva transforms industrial manufacturing supply chains into responsive, data-driven ecosystems. For supply chain managers, this integration provides the real-time insights needed to streamline operations, reduce costs, and enhance customer satisfaction.

In the industrial landscape, harnessing the power of real-time data is essential for staying competitive. By enabling supply chain managers to monitor, adjust, and optimize processes in real time, the integration of PlanetTogether and ERP systems helps achieve operational excellence and positions manufacturers for long-term success.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.