Production Planning for Customer Demands

Production Schedulers face daily challenges in balancing complex production demands with stringent regulatory standards and market pressures in the pharmaceutical industry. One critical element that can make or break production outcomes is production planning tailored to meet customer demands. When done right, effective production planning ensures customer satisfaction, reduces lead times, and enhances resource utilization.

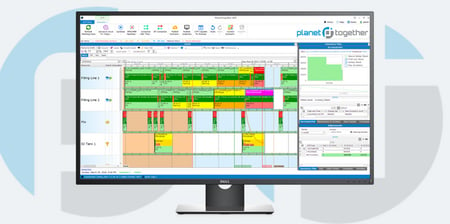

For pharmaceutical manufacturers, integrating advanced planning systems, like PlanetTogether, with robust ERP solutions like SAP, Oracle, Microsoft Dynamics, Kinaxis, or Aveva, adds a new layer of precision and responsiveness to production planning.

In this blog, we'll explore the unique demands of production planning in pharmaceutical manufacturing, the role of an integrated solution in meeting these demands, and how leveraging platforms like PlanetTogether with major ERPs can drive significant benefits for both schedulers and the overall supply chain.

The Complexity of Customer Demand in Pharmaceutical Manufacturing

In the pharmaceutical industry, customer demand is influenced by a variety of factors, including patient needs, regulatory requirements, and market shifts. Unlike many other industries, pharmaceutical production must adhere to stringent timelines, precise quality standards, and rigorous documentation processes.

Some of the main challenges Production Schedulers face in meeting customer demand include:

Demand Volatility: Pharmaceutical demand can fluctuate based on seasonality, health crises, or policy changes. This volatility makes it difficult to predict and meet demand without causing stockouts or overproduction.

Stringent Compliance Requirements: The pharmaceutical industry is governed by strict regulations (like the FDA’s Current Good Manufacturing Practice (CGMP) regulations), making it essential that production schedules align with quality and safety protocols.

Resource Constraints: Pharmaceutical production requires specialized equipment, skilled personnel, and sometimes scarce raw materials. Balancing these resources effectively is essential for keeping up with customer demand.

Complex Product Mix: Many pharmaceutical companies produce a wide range of products with varied production timelines. Aligning production with demand requires flexibility and scalability in scheduling processes.

Critical Time-to-Market Needs: As new drugs are developed and tested, timely production is essential. Delays can not only lead to lost revenue but also affect patient outcomes and competitive advantage.

The Role of Production Planning in Meeting Customer Demands

Production planning is the backbone of an efficient manufacturing operation, ensuring that all resources are effectively allocated to meet demand. For pharmaceutical manufacturers, a production plan that accounts for customer demand needs to be agile, accurate, and compliant with industry standards. A comprehensive production plan should include:

Forecasting and Demand Planning: Using historical data, trends, and predictive analytics to project future demand.

Capacity Planning: Understanding the manufacturing facility’s maximum output capabilities to avoid overburdening resources.

Inventory Management: Aligning raw materials and finished goods inventories to prevent stockouts or excesses.

Scheduling Flexibility: Allowing for adjustments based on real-time demand changes, equipment availability, and other factors.

Risk Management: Identifying potential risks in production and developing contingency plans to mitigate them.

Effective production planning can lead to improved customer satisfaction by ensuring that the right products are available at the right time while minimizing costs and resource wastage.

![]()

Integrating PlanetTogether with ERP Systems for Advanced Production Planning

While traditional production planning processes are essential, they can be significantly enhanced with integrated solutions. PlanetTogether, a powerful Advanced Planning and Scheduling (APS) system, offers capabilities that help production schedulers optimize resources, reduce bottlenecks, and adjust plans in real time. When integrated with leading ERP systems such as SAP, Oracle, Microsoft Dynamics, Kinaxis, or Aveva, PlanetTogether can offer even greater value.

Here’s how PlanetTogether, integrated with a robust ERP system, can enhance production planning:

Centralized Data Access: Integration ensures that data flows seamlessly between systems, allowing Production Schedulers to view real-time information on demand forecasts, inventory levels, and production capabilities without switching between platforms.

Real-Time Adjustments: Integrated APS and ERP systems enable Production Schedulers to make real-time adjustments to production schedules, minimizing delays and helping to meet customer demands even as they fluctuate.

Enhanced Forecast Accuracy: With data from the ERP system, PlanetTogether can utilize historical data and advanced forecasting algorithms to predict customer demand with greater precision. This helps in better aligning production schedules with expected market needs.

Streamlined Compliance Tracking: Integration with ERP systems enables automated compliance tracking, helping Production Schedulers maintain records that meet regulatory standards without additional administrative burden.

Improved Collaboration Across Departments: Integrated solutions foster collaboration between departments by making relevant data accessible to all stakeholders, including production, sales, procurement, and quality assurance.

Enhanced Resource Utilization: By providing an in-depth analysis of resource availability and capacity, integrated systems help Production Schedulers maximize resource utilization, minimizing downtime and reducing the need for emergency resource allocation.

Key Benefits of PlanetTogether Integration with Leading ERP Systems

The integration of PlanetTogether with SAP, Oracle, Microsoft Dynamics, Kinaxis, or Aveva offers Production Schedulers in the pharmaceutical industry several distinct advantages:

Visibility and Transparency: Real-time data integration provides end-to-end visibility into the supply chain, helping schedulers make informed decisions based on the latest information.

Reduced Lead Times: With real-time adjustments and optimized scheduling, production cycles become more efficient, reducing lead times and helping meet customer demand promptly.

Increased Agility: An integrated solution enables schedulers to adapt quickly to changes in demand, ensuring production aligns with real-time requirements.

Cost Reduction: Efficient resource utilization and minimized waste contribute to lower operational costs. This is particularly valuable in a cost-sensitive industry like pharmaceuticals.

Improved Customer Satisfaction: By delivering products on time and in full, pharmaceutical companies can increase customer satisfaction and build a stronger reputation in the market.

Best Practices for Production Schedulers in Pharmaceutical Manufacturing

To fully leverage the potential of PlanetTogether and ERP integration for production planning, Production Schedulers should consider the following best practices:

Invest in Training: Ensure that all team members are adequately trained to use both the APS and ERP systems effectively. This will reduce resistance to new processes and enable faster adaptation.

Embrace Data-Driven Decision Making: Use the data provided by these integrated solutions to make informed decisions and forecasts, taking advantage of real-time insights for more agile planning.

Align Production with Customer Demand Forecasts: Regularly update demand forecasts and adjust production schedules accordingly. This alignment helps in meeting customer demands without overburdening resources.

Implement a Continuous Improvement Process: Regularly evaluate and refine production schedules based on performance metrics provided by the integrated system. Continuous improvement will help in optimizing production processes and enhancing customer satisfaction.

Collaborate Cross-Functionally: Foster collaboration with procurement, quality assurance, and sales teams to ensure that production schedules align with overall business goals and customer expectations.

For Production Schedulers in pharmaceutical manufacturing, meeting customer demands requires more than just effective scheduling—it demands an integrated approach that aligns production with real-time data, optimizes resources, and maintains compliance. PlanetTogether’s APS capabilities, when integrated with ERP systems like SAP, Oracle, Microsoft Dynamics, Kinaxis, or Aveva, provide a comprehensive solution for addressing these challenges.

By leveraging this powerful integration, Production Schedulers can build resilient, responsive, and customer-centric production plans that not only meet demand but also drive operational excellence. This approach not only strengthens the company’s position in the market but also contributes to its reputation as a reliable and efficient pharmaceutical provider.

As customer demands continue to evolve, pharmaceutical manufacturers who embrace integrated solutions will be better equipped to navigate industry complexities and ensure customer satisfaction.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.

Topics: PlanetTogether Software, Reduced Lead Times, Real-time Adjustments, Enhanced resource utilization, Integrating PlanetTogether, Improved Customer Satisfaction, Enhanced Forecast Accuracy, Data Visibility and Transparency, Pharmaceutical Manufacturing, Streamlined Compliance Tracking, Centralized Data Access, Improved Collaboration Across Departments

LEAVE A COMMENT