Predictive Maintenance in Discrete Manufacturing for Improved Equipment Reliability and Efficiency

Any unplanned downtime or equipment failure can result in significant production losses, costly repairs, and even regulatory compliance issues in pharmaceutical manufacturing. Production planners play a crucial role in minimizing these risks, and one powerful tool at their disposal is predictive maintenance.

In this blog, we will explore how predictive maintenance, when integrated with advanced planning and scheduling tools like PlanetTogether, and Enterprise Resource Planning (ERP), Supply Chain Management (SCM), and Manufacturing Execution Systems (MES) solutions from companies like SAP, Oracle, Microsoft, Kinaxis, Aveva, and others, can revolutionize equipment reliability and efficiency in pharmaceutical manufacturing.

Equipment Reliability in Pharmaceutical Manufacturing

Pharmaceutical manufacturing is a highly regulated industry where product quality and patient safety are non-negotiable. To maintain the highest standards, it is essential to have reliable equipment that operates within specified tolerances. The consequences of equipment failures can be dire, including product recalls, financial losses, and damage to the reputation of the company.

To mitigate these risks, pharmaceutical manufacturers must focus on proactive maintenance strategies. Traditional maintenance approaches, such as reactive and preventive maintenance, have their limitations. Reactive maintenance only addresses issues after they occur, leading to costly downtime. Preventive maintenance, on the other hand, often involves servicing equipment based on a fixed schedule rather than its actual condition, leading to unnecessary maintenance costs.

Predictive maintenance takes a different approach by leveraging data, sensors, and advanced analytics to predict when equipment is likely to fail. By integrating predictive maintenance into the production planning process, production planners can proactively schedule maintenance activities during planned downtime, reducing unplanned downtime and minimizing disruption to production schedules.

![]()

Integrating Predictive Maintenance with Advanced Planning and Scheduling Tools

One of the key challenges in implementing predictive maintenance effectively is integrating it seamlessly with the existing production planning and scheduling processes. This is where advanced planning and scheduling (APS) tools like PlanetTogether come into play.

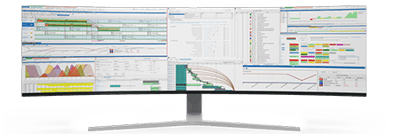

PlanetTogether is a powerful APS software that enables production planners to optimize production schedules, allocate resources efficiently, and balance workloads. When integrated with predictive maintenance data, it can take production planning to the next level by:

Predictive Scheduling: PlanetTogether can use predictive maintenance insights to reschedule production jobs and allocate resources to accommodate planned equipment maintenance. This ensures that maintenance activities are seamlessly integrated into the production schedule, reducing downtime.

Resource Optimization: By analyzing predictive maintenance data and historical equipment performance, PlanetTogether can help production planners allocate resources more effectively. It ensures that the right personnel and spare parts are available when needed, reducing idle time and improving overall equipment efficiency.

Scenario Planning: PlanetTogether allows for "what-if" scenario planning. This means production planners can simulate the impact of different maintenance schedules on production timelines, helping them make informed decisions about when and how to perform maintenance without disrupting production goals.

Integration with ERP, SCM, and MES Systems

To achieve a fully streamlined and efficient production environment, the integration of PlanetTogether's predictive maintenance capabilities with Enterprise Resource Planning (ERP), Supply Chain Management (SCM), and Manufacturing Execution Systems (MES) is essential. Let's delve into how this integration can enhance equipment reliability and efficiency:

ERP Integration (e.g., SAP, Oracle, Microsoft)

Real-time Data Sharing: Integrating predictive maintenance data from PlanetTogether with ERP systems ensures that production planners have access to the most up-to-date information. This allows for accurate demand forecasting and efficient resource allocation.

Inventory Management: ERP systems can optimize inventory levels based on production schedules adjusted for predictive maintenance. This minimizes the carrying costs associated with spare parts and ensures they are available when needed.

Compliance and Documentation: Pharmaceutical manufacturing requires strict adherence to regulatory requirements. Integration with ERP systems helps ensure that maintenance activities are documented correctly, aiding in compliance and audit readiness.

SCM Integration (e.g., Kinaxis, Aveva)

Supply Chain Visibility: SCM systems provide end-to-end visibility into the supply chain, allowing production planners to anticipate any potential disruptions caused by equipment downtime. This enables them to adjust procurement and logistics plans proactively.

Supplier Collaboration: SCM systems facilitate collaboration with suppliers, ensuring that critical spare parts and materials are readily available when needed for maintenance and reducing lead times.

MES Integration

Real-time Data Exchange: MES systems enable real-time data exchange between the shop floor and production planning. This ensures that maintenance activities are synchronized with actual equipment conditions, preventing unnecessary downtime.

Quality Control: MES systems can integrate with predictive maintenance data to monitor the quality of pharmaceutical products during production. This ensures that equipment reliability directly contributes to product quality.

Benefits of Integration

The integration of predictive maintenance with advanced planning and scheduling tools like PlanetTogether, along with ERP, SCM, and MES systems, offers a multitude of benefits to production planners in pharmaceutical manufacturing:

Reduced Downtime: Predictive maintenance allows for planned and proactive equipment servicing, minimizing unplanned downtime and production disruptions.

Improved Resource Utilization: Integration with advanced planning tools optimizes resource allocation, ensuring that personnel, spare parts, and materials are efficiently utilized.

Enhanced Product Quality: Predictive maintenance ensures that equipment is in optimal condition, contributing to consistent product quality and regulatory compliance.

Cost Savings: By avoiding costly breakdowns and optimizing maintenance schedules, pharmaceutical manufacturers can significantly reduce operational costs.

Data-Driven Decision-Making: Integration with ERP, SCM, and MES systems provides production planners with real-time data, enabling data-driven decision-making and continuous improvement.

In the highly regulated world of pharmaceutical manufacturing, equipment reliability and efficiency are paramount. Predictive maintenance, when integrated seamlessly with advanced planning and scheduling tools like PlanetTogether, as well as ERP, SCM, and MES systems from industry leaders like SAP, Oracle, Microsoft, Kinaxis, Aveva, and others, can transform production planning and maintenance processes.

Production planners can proactively schedule maintenance activities, optimize resource allocation, and ensure that equipment reliability directly contributes to product quality and regulatory compliance. The result is reduced downtime, improved resource utilization, cost savings, and data-driven decision-making—a winning combination for pharmaceutical manufacturers striving for excellence in equipment reliability and efficiency.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.

Topics: PlanetTogether Software, Improved Resource Utilization, Improved Equipment Reliability and Availability, Integrating PlanetTogether, Data-Driven Decision-Making, Reduced Downtime, Enhanced Product Quality, Cost Savings, Pharmaceutical Manufacturing

LEAVE A COMMENT