Optimizing Pricing Strategies

Pricing strategies are essential not only for profitability but also for sustaining a brand’s position in a complex and fluctuating landscape. The rising costs of ingredients, labor, and distribution, paired with changing consumer demands and regulatory pressures, necessitate a comprehensive approach to pricing that goes beyond traditional mark-up strategies.

For Operations Directors in the food and beverage sector, the focus is increasingly on leveraging technology to create dynamic, informed, and responsive pricing models.

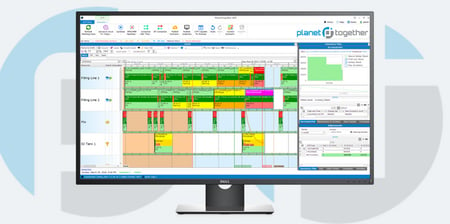

An effective pricing strategy requires real-time access to data, streamlined production planning, and the ability to make adjustments based on market trends. Integrating advanced production planning software like PlanetTogether with ERP systems such as SAP, Oracle, Microsoft, Kinaxis, or Aveva can provide the foundation needed for this level of insight and agility.

This blog explores how an integrated approach can empower food and beverage manufacturers to build competitive pricing strategies that are both profitable and sustainable.

Data-Driven Pricing in Food and Beverage Manufacturing

Traditional pricing methods, while straightforward, often lack the responsiveness needed in today’s volatile market. Many food and beverage manufacturers rely on cost-plus pricing, setting prices based on costs with a predefined profit margin. However, this method doesn’t account for fluctuations in raw material prices, changing customer preferences, or supply chain disruptions, which can heavily impact profitability.

To remain competitive, Operations Directors are increasingly turning to dynamic pricing strategies, which are based on real-time data and informed by predictive analytics. This shift from reactive to proactive pricing requires an integrated approach that consolidates data from production, inventory, supply chain, and sales. The integration of PlanetTogether with ERP systems offers food and beverage manufacturers a powerful toolkit for achieving this level of pricing agility.

![]()

Understanding the Role of Integrated Systems in Pricing Strategies

Integrated planning solutions combine production scheduling and ERP data, providing a centralized view of operational performance. Here’s how this works in practice:

Enhanced Visibility and Transparency: By connecting PlanetTogether with ERP systems, Operations Directors can gain a holistic view of the supply chain, from raw materials to finished products. This transparency is crucial in understanding costs, identifying areas where efficiencies can be improved, and anticipating price fluctuations. With the ability to see data in real time, manufacturers can react more quickly to changes in material costs or market demand, optimizing pricing as conditions evolve.

Predictive Analytics for Cost Management: Integrated systems support predictive analytics, which enables Operations Directors to anticipate cost changes and make informed pricing decisions. By analyzing historical data and market trends, the integration of PlanetTogether with platforms like SAP or Oracle can provide forecasts for material costs and production requirements. This predictive capability is invaluable for determining optimal pricing strategies, allowing companies to stay competitive without compromising margins.

Supply Chain Resilience and Flexibility: In the food and beverage industry, disruptions in the supply chain can significantly impact product availability and pricing. Integrated systems enable real-time tracking of inventory levels and supply chain performance, helping Operations Directors proactively manage stock levels, avoid stockouts, and optimize inventory costs. This proactive approach allows manufacturers to avoid price hikes due to shortages or delayed shipments, maintaining consistent and fair pricing for customers.

Key Benefits of Integrating PlanetTogether with Leading ERP Systems

By integrating PlanetTogether with ERP solutions like SAP, Oracle, Microsoft, Kinaxis, or Aveva, food and beverage manufacturers gain access to several valuable features that directly support effective pricing strategies:

Real-Time Cost Analysis: PlanetTogether's integration with ERP systems offers up-to-date information on production costs, including raw material costs, labor, and overhead. This data is essential for Operations Directors when setting prices that reflect current costs, helping prevent underpricing or overpricing products.

Automated Pricing Adjustments: With an integrated system, manufacturers can automate pricing updates based on cost changes, ensuring that pricing strategies remain aligned with profitability goals. This functionality is particularly useful in volatile markets, where prices may need to be adjusted frequently in response to fluctuating costs.

Scenario Planning and What-If Analysis: One of the key advantages of integrating planning tools with ERP systems is the ability to run scenarios and perform what-if analyses. For example, Operations Directors can model the impact of an increase in ingredient costs on pricing and margins. This level of foresight is invaluable for preparing pricing strategies that can absorb cost increases without negatively impacting demand or brand reputation.

Improved Demand Forecasting: Effective pricing is heavily dependent on accurate demand forecasting. Integrating PlanetTogether with ERP platforms allows manufacturers to combine historical sales data with production and inventory data, yielding more accurate forecasts. This enables Operations Directors to set prices that not only cover costs but also meet demand without oversupply or undersupply issues.

Enhanced Collaboration Across Departments: Pricing decisions don’t exist in isolation—they require collaboration across finance, production, supply chain, and sales departments. Integrating PlanetTogether with ERP systems creates a single source of truth, improving communication and collaboration. This cross-functional visibility ensures that pricing strategies are aligned with overall business objectives and operational constraints.

Implementing Integrated Pricing Strategies in Your Facility

For Operations Directors ready to enhance pricing strategies with PlanetTogether and ERP integration, here are a few steps to get started:

Define Clear Objectives: Begin by identifying the main goals of your pricing strategy, such as increasing profitability, managing costs, or improving market competitiveness. Having clear objectives will guide the integration process and ensure alignment with business goals.

Ensure Data Accuracy and Consistency: Reliable data is the foundation of any integrated system. Work closely with your IT team to ensure data integrity across PlanetTogether and your ERP system. Accurate data will empower you to make confident, data-driven decisions.

Train Your Team on New Capabilities: Integrated systems introduce new functionalities that may require training. Ensure that your team understands how to use these tools to monitor costs, forecast demand, and make pricing decisions based on real-time insights.

Leverage Predictive Analytics for Proactive Decision-Making: Encourage your team to use predictive analytics capabilities to anticipate cost fluctuations and adjust pricing strategies accordingly. These insights will allow you to maintain profitability even as market conditions change.

Regularly Review and Adjust Strategies: Pricing is not a set-and-forget process. Regularly review and analyze the performance of your pricing strategies, using insights from your integrated system to make adjustments as needed.

In the food and beverage industry, where margins are tight and market conditions are constantly changing, an effective pricing strategy can be the difference between profitability and loss. Integrating PlanetTogether with ERP systems like SAP, Oracle, Microsoft, Kinaxis, or Aveva provides Operations Directors with the tools needed to develop data-driven pricing strategies that adapt to real-time conditions.

With enhanced visibility, predictive analytics, and cross-departmental collaboration, food and beverage manufacturers can optimize their pricing strategies to reflect true production costs, meet consumer expectations, and maintain a competitive edge. Embracing this integrated approach not only improves profitability but also strengthens the resilience and agility of the entire organization, setting the stage for sustained success in a demanding market.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.

Topics: PlanetTogether Software, Integrating PlanetTogether, Improved Demand Forecasting, Scenario Planning and What-if Analysis, Enhanced Visibility and Transparency, Enhanced Collaboration Across Departments, Food and Beverage Manufacturing, Predictive Analytics for Cost Management, Supply Chain Resilience and Flexibility, Real-Time Cost Analysis

LEAVE A COMMENT