Optimizing Pharmaceutical Purchasing

The pharmaceutical industry is under constant pressure to maintain strict compliance with regulatory standards, manage complex supply chains, and meet high demands for product quality. In this challenging landscape, purchasing managers face the added difficulty of securing reliable suppliers while balancing cost efficiency and production continuity.

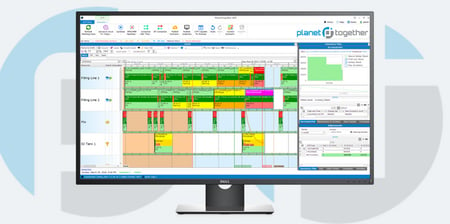

Leveraging advanced technology like PlanetTogether’s production planning and scheduling software integrated with major ERP and APS systems offer a powerful solution for overcoming these challenges.

This blog will explore how integrated systems streamline procurement processes, enhance compliance, and support cost-saving strategies in pharmaceutical manufacturing.

Integration in Pharmaceutical Purchasing

Pharmaceutical manufacturing is one of the most regulated industries, and purchasing managers must ensure that every material sourced meets stringent quality standards. The complexity is compounded by the need to coordinate with multiple departments—quality control, production, and compliance—all while navigating volatile supply chains.

![]()

PlanetTogether’s Integration with Leading ERP and APS Systems

By integrating PlanetTogether with ERP systems like SAP, Oracle, or Microsoft, and advanced planning systems (APS) like Kinaxis and Aveva, purchasing managers gain access to real-time data across departments. This centralized visibility helps streamline the sourcing process, ensuring materials are delivered just in time for production without overstocking inventory or risking shortages.

Key Benefits:

Enhanced Data Accuracy: PlanetTogether’s integration enables seamless data flow, reducing errors from manual data entry and ensuring accuracy.

Improved Communication Across Departments: Purchasing, production, and quality control can access unified data, allowing for better decision-making and faster response times to potential disruptions.

Real-Time Updates: With integration, purchasing managers can quickly assess and respond to supplier delays, production changes, and regulatory adjustments.

Streamlining Supplier Management with Integrated Solutions

One of the key responsibilities for pharmaceutical purchasing managers is managing supplier relationships and ensuring that vendors comply with stringent regulations. Integration with PlanetTogether allows managers to track supplier performance, evaluate risks, and streamline contract renewals.

Automating Supplier Audits and Compliance Checks: Integrated systems enable purchasing teams to automate essential tasks like supplier audits, quality checks, and compliance documentation. For instance, PlanetTogether’s integration with SAP or Oracle allows automatic updates to supplier qualifications and performance metrics, alerting purchasing managers to any discrepancies.

Benefits of Automated Supplier Management:

Risk Mitigation: Automated compliance tracking reduces the risk of working with non-compliant suppliers, safeguarding the supply chain.

Cost Efficiency: Streamlined supplier management minimizes the resources needed for manual checks, allowing teams to focus on strategic sourcing and supplier negotiations.

Improved Supplier Relationships: With up-to-date information, purchasing managers can work closely with suppliers to address quality or delivery issues proactively.

Optimizing Inventory and Reducing Costs

Pharmaceutical production schedules are highly sensitive to any fluctuations in material availability. Integrating PlanetTogether with ERP or APS solutions provides purchasing managers with real-time insights into inventory levels, order statuses, and production needs.

Strategic Inventory Management with Real-Time Data: With real-time data, purchasing managers can adopt a lean inventory approach, avoiding overstock or shortages. For instance, by integrating PlanetTogether with systems like Kinaxis or Aveva, purchasing can accurately predict demand based on production forecasts and adjust orders accordingly.

Key Advantages:

Reduced Holding Costs: Lean inventory minimizes storage costs and reduces the risk of material obsolescence.

Just-in-Time Purchasing: Purchasing managers can schedule material deliveries to align with production needs, reducing waste and enhancing efficiency.

Flexibility in Response to Market Changes: Integrated data allows purchasing teams to adjust orders dynamically, helping maintain agility in response to market changes.

Enhancing Compliance and Traceability

Compliance is a cornerstone of pharmaceutical manufacturing, and purchasing plays a crucial role in maintaining traceability from raw materials to finished products. PlanetTogether’s integration with ERP and APS solutions streamlines traceability, ensuring that all materials meet quality standards.

End-to-End Traceability: Integration allows purchasing managers to document every step in the procurement process, from initial orders to final quality checks. For instance, with SAP or Oracle integration, purchasing managers can easily access supplier records, certification statuses, and audit histories, which is essential for regulatory reporting.

Benefits:

Simplified Regulatory Reporting: Automatic traceability reduces the workload associated with preparing reports for regulatory bodies.

Quality Control and Risk Reduction: By maintaining detailed records, purchasing managers can quickly identify and address quality issues, ensuring that only compliant materials enter production.

Enhanced Product Recalls and Audits: If a product recall occurs, integrated systems simplify the process of tracing affected batches, speeding up response times.

Supporting Strategic Sourcing and Cost Optimization

Beyond day-to-day operations, purchasing managers are also tasked with implementing strategic sourcing practices to optimize costs. PlanetTogether’s integration with systems like Microsoft or Aveva provides powerful analytics and forecasting tools that support these efforts.

Data-Driven Decision-Making: Integrated data allows purchasing managers to analyze spending trends, evaluate supplier cost performance, and identify opportunities for savings. For example, by leveraging PlanetTogether’s forecasting tools with SAP’s analytics, purchasing managers can negotiate better rates with suppliers, adjust sourcing strategies, and optimize contracts.

Advantages of Strategic Sourcing:

Cost Reduction: Analytics help identify high-cost suppliers or materials, enabling more cost-effective alternatives.

Improved Supplier Negotiations: Data on supplier performance and cost trends provides leverage for negotiating better terms.

Increased Budget Control: Purchasing managers can make more accurate forecasts, enhancing budget accuracy and reducing unexpected expenses.

The Future of Pharmaceutical Purchasing with PlanetTogether and ERP Integration

As the pharmaceutical industry continues to embrace digital transformation, the role of technology in purchasing is set to grow. PlanetTogether’s integration with ERP and APS systems like SAP, Oracle, Microsoft, Kinaxis, and Aveva represents a shift towards a more agile, data-driven approach to purchasing.

Adopting Predictive Analytics and Machine Learning: With advancements in predictive analytics and machine learning, purchasing managers can make even more informed decisions, reducing waste, optimizing supplier selection, and enhancing cost control. The integration of these tools with PlanetTogether further empowers purchasing managers to anticipate demand and adapt sourcing strategies proactively.

Collaborative Digital Ecosystems: Integrated platforms foster a collaborative environment where purchasing managers can work closely with suppliers and internal teams, driving continuous improvement and innovation. As pharmaceutical manufacturing evolves, purchasing managers who leverage these integrated systems will be better equipped to navigate an increasingly complex and competitive market.

PlanetTogether’s integration with ERP and APS solutions such as SAP, Oracle, Microsoft, Kinaxis, and Aveva offers pharmaceutical purchasing managers a unique opportunity to optimize their workflows, enhance compliance, and drive strategic sourcing. By harnessing the power of real-time data, automation, and predictive insights, purchasing managers can make data-driven decisions that improve efficiency, reduce costs, and ensure the highest standards of quality and compliance.

Embracing this integrated approach positions pharmaceutical companies to stay competitive while delivering safe and effective products to market.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.

Topics: PlanetTogether Software, Real-Time Updates, Integrating PlanetTogether, Improved Cost Optimization, Enhanced Data Accuracy, Pharmaceutical Manufacturing, Improved Communication Across Departments, Optimizing Inventory and Reducing Costs, Enhancing Compliance and Traceability, Supporting Strategic Sourcing

LEAVE A COMMENT