Resource Allocation with Predictive Algorithms

In pharmaceutical manufacturing, staying ahead of the curve is crucial for maintaining competitiveness and ensuring product quality and efficiency. Purchasing Managers play a pivotal role in this ecosystem, responsible for procuring the necessary resources while balancing cost-effectiveness and productivity.

With the advent of predictive algorithms and advanced integration between planning systems like PlanetTogether and enterprise resource planning (ERP), supply chain management (SCM), and manufacturing execution systems (MES) such as SAP, Oracle, Microsoft, Kinaxis, and Aveva, a new era of resource allocation has emerged.

This blog explores how leveraging predictive algorithms can enhance resource allocation in pharmaceutical manufacturing facilities, driving efficiency, reducing costs, and ultimately improving outcomes.

Enhanced Resource Allocation

Resource allocation in pharmaceutical manufacturing involves the judicious distribution of materials, equipment, and manpower to meet production demands while optimizing efficiency and minimizing waste. Traditionally, this process relied heavily on historical data, manual planning, and reactive decision-making. However, with the proliferation of predictive analytics and algorithmic modeling, manufacturers now have the tools to forecast demand, anticipate bottlenecks, and optimize resource allocation in real-time.

Predictive Algorithms

Predictive algorithms utilize historical data, machine learning techniques, and advanced statistical analysis to forecast future trends and outcomes. In the context of pharmaceutical manufacturing, these algorithms can predict demand fluctuations, identify potential supply chain disruptions, and optimize production schedules. By analyzing vast amounts of data from disparate sources, including production records, inventory levels, market trends, and supplier performance, predictive algorithms empower Purchasing Managers to make informed decisions that drive operational excellence.

Integration with Planning Systems

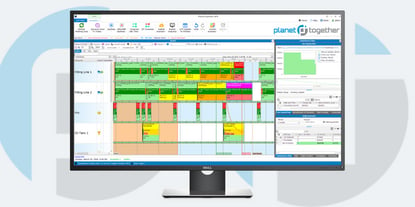

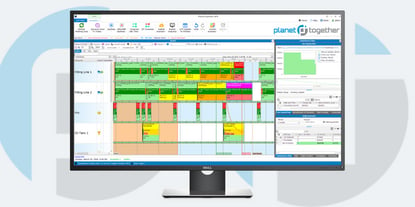

The seamless integration between predictive algorithms and planning systems such as PlanetTogether offers a holistic approach to resource allocation. PlanetTogether's advanced planning and scheduling capabilities, combined with predictive analytics, enable Purchasing Managers to create optimized production schedules that align with demand forecasts and resource availability.

By integrating with ERP, SCM, and MES systems like SAP, Oracle, Microsoft, Kinaxis, and Aveva, manufacturers can achieve end-to-end visibility across the supply chain, from procurement to production to distribution.

Enhanced Resource Allocation with Integration

Integration between PlanetTogether and leading ERP, SCM, and MES systems such as SAP, Oracle, Microsoft Dynamics, Kinaxis, Aveva, and others is pivotal in achieving seamless data exchange and synchronization. By consolidating data from disparate sources into a centralized platform, manufacturers gain a holistic view of their operations, enabling informed decision-making and agile resource allocation.

Here's how integration with these systems enhances resource allocation:

Real-Time Visibility: Integration allows for real-time data exchange between PlanetTogether and ERP systems, providing up-to-date visibility into inventory levels, production schedules, and customer demands. This visibility enables Purchasing Managers to adjust procurement strategies, allocate materials efficiently, and mitigate supply chain risks effectively.

Demand Forecasting and Planning: By leveraging historical data and predictive analytics, integrated systems facilitate accurate demand forecasting and production planning. Purchasing Managers can anticipate market trends, optimize inventory levels, and align procurement with production schedules, ensuring timely delivery of products while minimizing excess inventory and stockouts.

Dynamic Scheduling and Optimization: Integration with MES systems enables dynamic scheduling and optimization of manufacturing processes based on real-time performance data. PlanetTogether can adapt production schedules in response to machine downtime, material shortages, or changing priorities, maximizing equipment utilization and minimizing idle time.

Compliance and Traceability: In the highly regulated pharmaceutical industry, compliance with quality standards and traceability requirements is paramount. Integration between systems ensures seamless traceability of materials, ingredients, and finished products throughout the supply chain, facilitating compliance with regulatory mandates and quality assurance protocols.

Continuous Improvement: By capturing data on production performance and resource utilization, integrated systems support continuous improvement initiatives. Purchasing Managers can identify areas for optimization, implement process enhancements, and measure the impact of changes on overall efficiency and profitability.

Benefits of Enhanced Resource Allocation

Optimized Inventory Management: Predictive algorithms help minimize stockouts and excess inventory by accurately forecasting demand and adjusting procurement schedules accordingly. This leads to cost savings and improved cash flow.

Reduced Lead Times: By proactively identifying potential bottlenecks and capacity constraints, Purchasing Managers can preemptively allocate resources to mitigate delays and minimize lead times.

Improved Supplier Collaboration: Predictive analytics facilitate proactive communication with suppliers, enabling Purchasing Managers to anticipate supply chain disruptions and collaborate on contingency plans.

Enhanced Quality Control: By optimizing resource allocation, manufacturers can ensure consistent product quality by maintaining optimal production conditions and minimizing deviations.

Increased Efficiency: Streamlined production schedules and optimized resource utilization result in higher throughput and reduced idle time, ultimately enhancing overall operational efficiency.

In the pharmaceutical manufacturing industry, enhanced resource allocation is essential for maintaining competitiveness and driving operational efficiency. By leveraging predictive algorithms and integrating with advanced planning systems like PlanetTogether and ERP, SCM, and MES platforms such as SAP, Oracle, Microsoft, Kinaxis, and Aveva, Purchasing Managers can optimize production schedules, minimize costs, and improve product quality.

As technology continues to evolve, embracing predictive analytics will be key to staying ahead of the curve and achieving sustainable growth in the pharmaceutical manufacturing sector. Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.

LEAVE A COMMENT