Integration and Benefits of CMPS with PlanetTogether

In manufacturing, where agility, precision, and efficiency are essential, the integration of advanced technologies has become indispensable. One such innovation that is reshaping the manufacturing planning process is Cognitive Manufacturing Planning Systems (CMPS), empowered by artificial intelligence (AI) and machine learning (ML).

When integrated with leading Advanced Planning and Scheduling (APS) software like PlanetTogether, CMPS unlocks a new realm of possibilities, revolutionizing how manufacturers optimize production schedules, manage resources, and drive operational excellence.

Let's look into the benefits and integration of CMPS with PlanetTogether

Understanding Cognitive Manufacturing Planning Systems (CMPS)

CMPS leverages AI and ML algorithms to analyze vast amounts of data in real-time, enabling manufacturers to predict demand fluctuations, optimize production schedules, and mitigate risks proactively. Key components of CMPS include data integration, predictive analytics, optimization algorithms, prescriptive recommendations, and continuous learning, all aimed at driving continuous improvement across the manufacturing value chain.

Integration of CMPS with PlanetTogether

PlanetTogether is a leading APS software that empowers manufacturers to optimize production schedules, manage resources, and improve on-time delivery performance. When integrated with CMPS, PlanetTogether serves as a critical data source, providing real-time updates on production orders, capacity constraints, material availability, and shop floor operations. The integration between CMPS and PlanetTogether enables:

Real-time Data Exchange

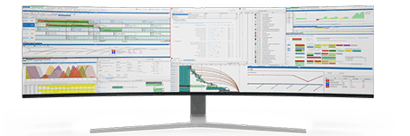

CMPS seamlessly integrates with PlanetTogether, allowing for the exchange of real-time data on production schedules, resource availability, and demand forecasts. This real-time data exchange ensures that CMPS has access to the most up-to-date information, enabling more accurate predictions and optimization recommendations.

Enhanced Predictive Analytics

By leveraging PlanetTogether's data, CMPS enhances its predictive analytics capabilities, enabling manufacturers to anticipate demand fluctuations, identify production bottlenecks, and optimize scheduling decisions accordingly. This integration enables manufacturers to stay ahead of market dynamics and customer demands, leading to improved responsiveness and customer satisfaction.

Optimized Production Scheduling

CMPS uses PlanetTogether's production scheduling data to generate optimized production schedules that balance supply and demand, minimize changeovers, and maximize resource utilization. By integrating CMPS with PlanetTogether, manufacturers can achieve higher throughput, reduced lead times, and lower production costs.

Proactive Issue Resolution

The integration of CMPS with PlanetTogether enables proactive issue resolution by monitoring key performance indicators (KPIs), alerts, and exceptions in real-time. Manufacturers can identify and address issues such as equipment failures, material shortages, or production delays before they escalate, minimizing disruptions and optimizing operational efficiency.

Seamless Collaboration

CMPS facilitates seamless collaboration between different functional areas within the manufacturing organization, including production planning, inventory management, and shop floor operations. By integrating with PlanetTogether, CMPS enables cross-functional teams to work together more effectively, aligning production schedules with business objectives and customer demands.

-May-08-2024-04-36-12-8483-PM.png?width=300&height=48&name=logo%20(2)-May-08-2024-04-36-12-8483-PM.png)

Benefits of Integrating CMPS with PlanetTogether

The integration of CMPS with PlanetTogether offers a myriad of benefits for manufacturers, including:

Improved Production Efficiency: By optimizing production schedules and resource utilization, CMPS integrated with PlanetTogether enables manufacturers to achieve higher throughput, reduced lead times, and lower production costs.

Enhanced Predictive Insights: Leveraging real-time data from PlanetTogether, CMPS provides more accurate demand forecasts, enabling manufacturers to anticipate market trends and customer demands more effectively.

Proactive Issue Resolution: The integration of CMPS with PlanetTogether enables manufacturers to identify and address issues in real-time, minimizing disruptions and optimizing operational efficiency.

Seamless Collaboration: CMPS facilitates seamless collaboration between different functional areas within the manufacturing organization, enabling cross-functional teams to work together more effectively towards common goals.

Continuous Improvement: By leveraging machine learning algorithms, CMPS integrated with PlanetTogether continuously learns from new data inputs, identifying optimization opportunities and driving continuous improvement across the manufacturing value chain.

The integration of Cognitive Manufacturing Planning Systems (CMPS) with leading Advanced Planning and Scheduling (APS) software like PlanetTogether unlocks a new level of efficiency, agility, and competitiveness for manufacturers.

By seamlessly exchanging real-time data, enhancing predictive analytics, optimizing production schedules, enabling proactive issue resolution, and fostering seamless collaboration, CMPS integrated with PlanetTogether empowers manufacturers to stay ahead of market dynamics, optimize resources, and drive operational excellence in today's rapidly evolving manufacturing landscape.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.