Production Line Layout Using AI Simulations

Optimizing production processes is not just a goal but a necessity for staying competitive in industrial manufacturing. As a Plant Manager, you're well aware of the challenges involved in balancing efficiency, productivity, and cost-effectiveness. One of the critical aspects of achieving this balance lies in the layout of your production lines. A well-optimized production line layout can significantly enhance operational efficiency, minimize waste, and maximize output.

Traditionally, designing or reconfiguring production line layouts involved a considerable amount of trial and error, often leading to suboptimal results and costly downtime. However, with advancements in technology, particularly in the realm of Artificial Intelligence (AI) and simulation software, plant managers now have powerful tools at their disposal to streamline this process and achieve optimal results.

In this blog, we'll look into the concept of optimized production line layout using AI simulations and explore how integrating solutions like PlanetTogether with ERP, SCM, and MES systems such as SAP, Oracle, Microsoft, Kinaxis, and Aveva can revolutionize manufacturing operations.

The Importance of Production Line Layout Optimization

The layout of production lines plays a pivotal role in determining the efficiency and effectiveness of manufacturing operations. A well-designed layout takes into account various factors such as workflow, material flow, equipment placement, and personnel movement to ensure smooth and seamless production processes.

Optimizing production line layouts offers several key benefits:

Enhanced Efficiency: By minimizing bottlenecks, reducing material handling, and optimizing the flow of goods and personnel, an optimized layout can significantly improve overall efficiency.

Increased Productivity: A well-organized production line layout can help reduce idle time, shorten cycle times, and increase throughput, ultimately boosting productivity levels.

Cost Reduction: Optimized layouts can lead to savings in terms of reduced labor costs, lower energy consumption, and decreased waste, contributing to overall cost reduction.

Flexibility and Adaptability: With a modular and flexible layout, manufacturers can easily adapt to changes in production requirements, market demands, and product variations without major disruptions.

Challenges in Traditional Layout Design Methods

Despite the importance of production line layout optimization, traditional methods of design and analysis often fall short in addressing the complexities of modern manufacturing environments. Some of the common challenges include:

Manual and Time-Consuming: Traditional layout design methods rely heavily on manual calculations, assumptions, and trial-and-error approaches, consuming valuable time and resources.

Limited Visibility: Traditional approaches may lack comprehensive insights into the dynamic interactions and dependencies within the production system, leading to suboptimal decisions.

Inability to Account for Variability: Manufacturing environments are inherently dynamic, with fluctuations in demand, supply chain disruptions, and changes in product mix. Traditional methods may struggle to account for this variability effectively.

Risk of Disruption: Making significant changes to production line layouts based on trial and error can pose risks of operational disruption, downtime, and inefficiencies.

Enter AI-Powered Simulation Solutions

The advent of AI-powered simulation software has transformed the landscape of production line layout optimization. These advanced solutions leverage the power of artificial intelligence, machine learning, and predictive analytics to simulate and optimize complex manufacturing processes in a virtual environment.

One such leading solution is PlanetTogether, a cutting-edge production planning and scheduling software that offers advanced simulation capabilities for optimizing production line layouts. By integrating PlanetTogether with ERP, SCM, and MES systems such as SAP, Oracle, Microsoft, Kinaxis, and Aveva, plant managers can harness the full potential of AI-driven optimization.

Key Features and Benefits of PlanetTogether Integration:

Data Integration: Seamless integration with ERP, SCM, and MES systems enables real-time data exchange, providing accurate information on production schedules, inventory levels, and resource availability.

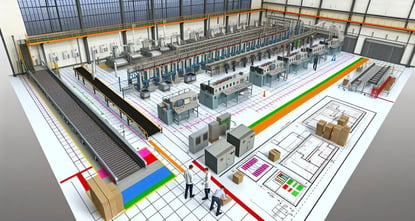

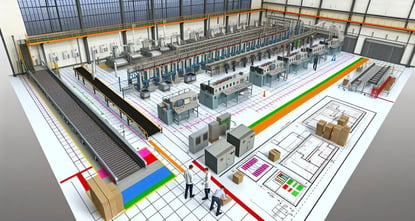

Advanced Simulation Modeling: PlanetTogether's AI-driven simulation engine allows plant managers to create detailed digital replicas of their production facilities, including equipment, workflows, and material flows. This enables them to visualize and analyze different layout configurations and scenarios.

Optimization Algorithms: PlanetTogether employs sophisticated optimization algorithms to evaluate countless layout permutations and identify the most efficient configurations based on predefined objectives such as minimizing cycle time, maximizing throughput, or minimizing resource utilization.

What-If Analysis: With PlanetTogether's what-if analysis capabilities, plant managers can assess the potential impact of changes to production line layouts before implementation, reducing the risk of costly errors and disruptions.

Continuous Improvement: By leveraging historical data and performance metrics, PlanetTogether enables continuous improvement through iterative simulation and optimization cycles, ensuring that production line layouts remain optimized in response to changing conditions.

The integration of AI-powered simulation solutions like PlanetTogether with ERP, SCM, and MES systems represents a paradigm shift in the way production line layouts are optimized in industrial manufacturing facilities. By leveraging advanced algorithms, predictive analytics, and real-time data integration, plant managers can achieve unprecedented levels of efficiency, productivity, and flexibility.

As a Plant Manager, embracing AI-driven optimization is not just a competitive advantage but a strategic imperative for staying ahead in today's dynamic manufacturing landscape. By harnessing the power of AI simulations, you can unlock new opportunities for continuous improvement, innovation, and sustainable growth in your production operations.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.

LEAVE A COMMENT