Operational Excellence in Medical Manufacturing

Achieving operational excellence is a perpetual objective, but it’s no easy feat in medical manufacturing. Between ensuring compliance with stringent regulatory standards, maintaining high product quality, and optimizing production efficiency, the pressure on Plant Managers is immense. A key enabler for Plant Managers striving for operational excellence lies in leveraging integrated manufacturing systems. When systems like PlanetTogether are combined with enterprise solutions such as SAP, Oracle, Microsoft, Kinaxis, or Aveva, the impact on operational performance can be transformative.

What is Operational Excellence?

Operational excellence in manufacturing can be defined as consistently executing a manufacturing strategy more effectively and efficiently than competitors. It revolves around the continuous improvement of processes, people, and technology. In medical manufacturing, achieving operational excellence means not only driving efficiency but also ensuring that every product meets stringent quality and safety standards. This dual focus on productivity and compliance demands a sophisticated, data-driven approach to production planning, scheduling, and resource management.

The Role of Integrated Manufacturing Systems in Achieving Operational Excellence

Medical manufacturing facilities, unlike those in other sectors, often grapple with unique challenges, including:

Strict regulatory requirements that demand thorough tracking of all materials and processes.

Complex product lines with high variability and precision requirements.

Long lead times due to the rigorous testing and validation protocols.

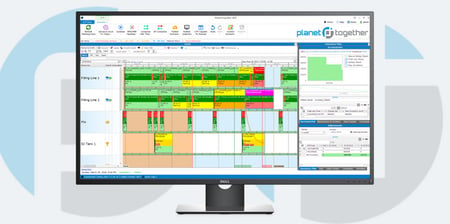

To address these complexities, an integrated manufacturing system that includes advanced scheduling and planning, like PlanetTogether, combined with ERP or other enterprise systems like SAP, Oracle, Microsoft, Kinaxis, or Aveva, can prove essential. This combination not only centralizes data but also creates a seamless flow of information across departments, enabling more strategic decision-making.

![]()

Benefits of Integrating PlanetTogether with ERP Systems for Operational Excellence

By integrating PlanetTogether with ERP systems, medical manufacturers can streamline operations, reduce waste, and optimize production schedules in ways that weren’t possible before. Here’s how integrated systems support operational excellence:

Enhanced Visibility and Real-Time Data Access

Integrating PlanetTogether with enterprise systems allows for real-time visibility into production processes. For Plant Managers, this visibility is crucial in:

Tracking production metrics in real-time: Whether it’s tracking yields, machine utilization, or production costs, real-time data empowers managers to make quick, informed decisions.

Improving inventory management: Integrated data helps manage raw materials, in-progress products, and finished goods more effectively, reducing inventory waste.

Monitoring compliance metrics: By consolidating compliance-related data in a single view, Plant Managers can ensure that every step of the manufacturing process aligns with regulatory requirements.

For example, if a Plant Manager at a medical manufacturing facility integrates PlanetTogether with SAP, they gain a unified view of inventory, production schedules, and quality metrics, making it easier to track adherence to regulatory standards and make adjustments as needed.

Optimized Production Scheduling and Reduced Downtime

Medical manufacturing facilities can lose significant productivity and revenue due to unplanned downtime and inefficient scheduling. PlanetTogether’s scheduling capabilities allow Plant Managers to optimize workflows and minimize downtime. When PlanetTogether is integrated with an ERP system like Oracle or Microsoft Dynamics, scheduling can be fully aligned with order fulfillment, inventory levels, and maintenance schedules.

Enhanced planning and scheduling flexibility: The integration enables Plant Managers to adjust schedules quickly based on inventory shortages, order changes, or equipment availability.

Predictive maintenance scheduling: Integrating data from PlanetTogether and other systems enables predictive maintenance, reducing the risk of unplanned downtime and ensuring equipment is operational when needed.

For instance, integrating PlanetTogether with Oracle’s ERP system provides Plant Managers with real-time data on machine health and performance, allowing them to optimize maintenance schedules, thereby reducing downtime and improving throughput.

Data-Driven Quality Management

In the medical manufacturing sector, product quality isn’t just a priority; it’s a mandate. Poor quality control can lead to regulatory actions, recalls, and severe reputational damage. By integrating PlanetTogether with platforms like Aveva or SAP, manufacturers can leverage data from multiple sources to improve quality management:

Early detection of quality issues: Integrated data can help identify issues early in the production process, allowing for corrective actions before the product reaches the end of the line.

Automated compliance reporting: Integrated systems make compliance reporting far more efficient by centralizing all necessary data, reducing the time and risk associated with manual tracking.

Enhanced traceability: The combined power of PlanetTogether and ERP systems enables traceability from raw materials to finished products, a critical component of quality management in medical manufacturing.

For example, a Plant Manager who integrates PlanetTogether with Aveva gains the ability to automate quality checks and track compliance across production runs, ensuring every product meets exacting standards.

Improved Resource Utilization and Waste Reduction

Waste in medical manufacturing goes beyond raw material loss. It includes wasted time, effort, and resources when production processes are not streamlined. Integration between PlanetTogether and ERP systems like Kinaxis can help:

Optimize labor allocation: Integrated systems can automatically adjust schedules and resource allocations based on production demands, reducing idle time and labor costs.

Reduce material waste: By aligning production schedules with inventory data, integrated systems ensure that materials are used efficiently, minimizing waste due to expired or unused components.

Sustainable manufacturing: Efficient resource utilization contributes to sustainability goals, a growing focus in the medical manufacturing sector.

For instance, by integrating PlanetTogether with Kinaxis, Plant Managers can align production schedules with procurement and inventory, ensuring that materials are used before expiration and that production runs are sized appropriately, reducing both material waste and production costs.

The Strategic Value of Integrated Systems for the Plant Manager

For a Plant Manager, the primary benefit of integrating PlanetTogether with enterprise systems lies in the strategic value it brings to everyday decision-making. Here’s how this integration supports strategic initiatives and drives operational excellence:

Holistic decision-making: The integration provides a unified view of the entire production process, allowing Plant Managers to make decisions based on accurate, up-to-date data from multiple systems.

Faster response times: Integrated data accelerates the time from insight to action, enabling managers to respond to production challenges before they escalate.

Reduced operational risk: By enhancing compliance, quality control, and scheduling efficiency, integrated systems reduce the risk of costly disruptions and regulatory actions.

A Plant Manager using an integrated system with PlanetTogether and SAP, for example, can proactively manage both day-to-day operations and longer-term production strategies, making it easier to align facility operations with corporate objectives and improve the bottom line.

Achieving operational excellence in medical manufacturing requires a careful balance of efficiency, quality, and compliance. Integrated systems like PlanetTogether, combined with ERP platforms such as SAP, Oracle, Microsoft, Kinaxis, or Aveva, can significantly enhance a Plant Manager’s ability to meet these demands. By enabling real-time visibility, optimizing scheduling, and enhancing quality management, these integrated systems empower Plant Managers to make data-driven decisions that improve operational performance.

Investing in system integration will be increasingly essential for manufacturers aiming to remain competitive and compliant. For Plant Managers, the journey to operational excellence starts with the right tools, and integrating PlanetTogether with ERP solutions is a powerful step in that direction.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.

Topics: PlanetTogether Software, Integrating PlanetTogether, Optimized Production Scheduling, Reduced Downtime, Medical Manufacturing, Enhanced Visibility and Real-Time Data Access, Data-Driven Quality Management, Improved Resource Utilization and Waste Reduction

LEAVE A COMMENT