Flexible Supply Chain for Rapid Market Changes

Market demands are constantly evolving, presenting both opportunities and challenges for supply chain managers. The ability to adapt quickly to these changes is crucial for the success and sustainability of any packaging manufacturing facility.

In this blog, we'll look into the importance of building a flexible supply chain and explore how integration between PlanetTogether and leading ERP, SCM, and MES systems can empower supply chain managers to respond effectively to rapid shifts in market demands.

The Need for Flexibility

The packaging industry operates in a volatile market where consumer preferences, regulatory requirements, and competitive forces can change rapidly. Supply chain managers must anticipate and respond to these changes swiftly to avoid disruptions and maintain customer satisfaction. A rigid supply chain can hinder adaptability, leading to inefficiencies, excess inventory, and missed opportunities. Therefore, the ability to build flexibility into every aspect of the supply chain is essential for success.

Challenges in Achieving Supply Chain Flexibility

While the importance of flexibility is clear, many packaging manufacturers struggle to achieve it due to various challenges. These may include:

Fragmented Systems: Siloed systems and disparate data sources make it difficult to gain real-time visibility and orchestrate operations seamlessly.

Limited Scalability: Traditional supply chain solutions may lack the scalability to handle fluctuations in demand or sudden market shifts effectively.

Inefficient Planning Processes: Manual planning processes and outdated tools hinder agility and responsiveness, leading to delays and inefficiencies.

Lack of Integration: Poor integration between planning, execution, and monitoring systems inhibits communication and coordination across the supply chain network.

The Role of Integration

Integration plays a pivotal role in overcoming these challenges and fostering a flexible supply chain. By connecting planning, execution, and monitoring systems, integration enables seamless data flow, real-time visibility, and synchronized operations.

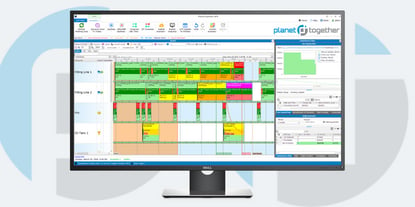

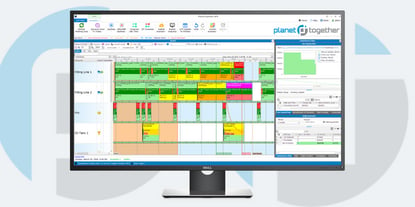

PlanetTogether, a leading advanced planning and scheduling (APS) software, offers robust integration capabilities with various ERP, SCM, and MES systems, including SAP, Oracle, Microsoft Dynamics, Kinaxis, and Aveva, among others. This integration empowers supply chain managers with:

Real-Time Visibility: Integration allows for the exchange of data between different systems, providing supply chain managers with real-time visibility into inventory levels, production schedules, and order statuses.

Streamlined Processes: Integrated systems streamline processes by automating data exchange and eliminating manual interventions, reducing lead times and improving overall efficiency.

Data Consistency: Integration ensures data consistency across the supply chain, enabling accurate forecasting, planning, and decision-making.

Agile Decision-Making: With access to timely and accurate information, supply chain managers can make informed decisions quickly, adapting to changing market conditions with agility.

End-to-End Optimization: Integration enables end-to-end optimization of the supply chain, from demand planning and production scheduling to inventory management and order fulfillment.

Building a Flexible Supply Chain with PlanetTogether Integration

Integrating PlanetTogether with ERP, SCM, and MES systems lays the foundation for building a flexible supply chain that can respond rapidly to market changes. Here's how supply chain managers can leverage this integration to enhance flexibility:

Dynamic Demand Planning: By integrating demand forecasting modules with PlanetTogether, supply chain managers can generate accurate demand forecasts based on real-time market data, enabling proactive planning and resource allocation.

Agile Production Scheduling: Integration between PlanetTogether and manufacturing execution systems (MES) enables agile production scheduling, allowing manufacturers to adjust production schedules in response to changing demand patterns, equipment availability, and resource constraints.

Optimized Inventory Management: Integration with ERP systems facilitates optimized inventory management by synchronizing inventory levels with production schedules and customer orders, minimizing excess inventory while ensuring product availability.

Responsive Order Fulfillment: With integration between PlanetTogether and order management systems, supply chain managers can prioritize and allocate resources efficiently to meet customer orders in a timely manner, even during periods of high demand or supply chain disruptions.

Continuous Improvement: Integrated data analytics capabilities enable supply chain managers to monitor key performance indicators (KPIs), identify bottlenecks, and drive continuous improvement initiatives across the supply chain network.

Building a flexible supply chain is imperative for packaging manufacturers to thrive in today's volatile market environment. Integration between advanced planning and scheduling solutions like PlanetTogether and leading ERP, SCM, and MES systems is key to achieving supply chain flexibility.

By leveraging integration capabilities, supply chain managers can enhance visibility, streamline processes, and drive agility across the supply chain network, enabling rapid responses to market changes and delivering superior value to customers.

In a world where change is the only constant, a flexible supply chain powered by integration is the cornerstone of success for packaging manufacturers seeking to stay ahead of the curve. Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.

LEAVE A COMMENT