Multi-Objective Optimization in Production Schedules: A Path to Excellence in Medical Manufacturing

In medical manufacturing, production scheduling is a critical task requiring precision, efficiency, and flexibility. For Production Schedulers, managing multiple objectives—such as minimizing production costs, ensuring compliance with stringent regulations, and meeting customer delivery timelines—can feel like a high-stakes juggling act.

This blog explores the concept of multi-objective optimization in production scheduling and how integrating tools like PlanetTogether with systems such as SAP, Oracle, Microsoft, Kinaxis, or Aveva can revolutionize operations in medical manufacturing.

The Complexity of Production Scheduling in Medical Manufacturing

Medical manufacturing is unlike other industries due to its unique set of challenges:

Regulatory Compliance: Adherence to strict guidelines from entities like the FDA or EMA requires meticulous planning and documentation.

Product Variability: Manufacturing ranges from single-use devices to complex diagnostic equipment, each with distinct production processes.

Demand Volatility: The industry often sees spikes in demand due to public health emergencies or changing medical needs.

Cost Pressures: Rising raw material costs and intense competition make cost management essential.

Production Schedulers must balance these competing priorities while ensuring that operations remain efficient and compliant.

What is Multi-Objective Optimization?

Multi-objective optimization involves finding the best possible solutions to multiple, often conflicting objectives. For example, a Production Scheduler may aim to:

- Minimize production lead times.

- Maximize machine utilization.

- Reduce material waste.

- Ensure compliance with quality standards.

- Stay within budget constraints.

Traditional scheduling approaches often focus on a single goal, such as minimizing costs or maximizing throughput. However, these methods may not fully address the complex requirements of modern medical manufacturing. Multi-objective optimization provides a more holistic approach, enabling schedulers to prioritize and balance multiple goals simultaneously.

![]()

The Role of Advanced Scheduling Tools

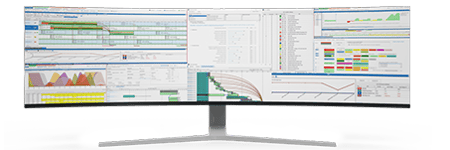

Tools like PlanetTogether, especially when integrated with enterprise systems such as SAP, Oracle, Microsoft, Kinaxis, or Aveva, offer Production Schedulers the ability to harness multi-objective optimization effectively. These integrations create a seamless flow of data across systems, enabling more informed decision-making and better overall outcomes.

Key Features of PlanetTogether in Multi-Objective Optimization

Dynamic Scheduling: Adapt schedules in real-time to account for unexpected disruptions, such as equipment downtime or urgent orders.

Scenario Planning: Evaluate multiple "what-if" scenarios to understand the trade-offs between different scheduling decisions.

Constraint Management: Address constraints like limited machine capacity, labor availability, or regulatory requirements.

Performance Metrics: Track key performance indicators (KPIs) such as on-time delivery rates, machine utilization, and inventory levels.

Benefits of Integrating PlanetTogether with Enterprise Systems

Enhanced Data Visibility

Integration between PlanetTogether and ERP systems like SAP or Oracle ensures that all relevant data—inventory levels, work orders, and production timelines—is centralized. This comprehensive view allows schedulers to make decisions based on the most accurate and up-to-date information.

For example, if a raw material delay is recorded in SAP, PlanetTogether can automatically adjust the production schedule to minimize disruptions, ensuring that other objectives, such as delivery timelines, are still met.

Improved Collaboration

Collaboration between departments, such as procurement, production, and quality assurance, is vital in medical manufacturing. Integration with tools like Microsoft Dynamics enhances communication by providing a shared platform for all stakeholders. This alignment reduces bottlenecks and ensures that all teams are working toward the same objectives.

Optimization Across the Supply Chain

By connecting PlanetTogether with Kinaxis, schedulers can extend optimization beyond the factory floor to include supply chain considerations. This integration helps balance production schedules with supplier lead times, transportation costs, and inventory levels, creating a more synchronized and efficient operation.

Compliance and Traceability

Medical manufacturing requires detailed traceability of materials and processes. Integration with Aveva enables enhanced tracking and reporting capabilities, ensuring that all compliance requirements are met. Schedulers can focus on optimizing production without worrying about falling short of regulatory standards.

Multi-objective optimization is not just a buzzword—it’s a must for modern medical manufacturing. For Production Schedulers, leveraging advanced tools like PlanetTogether, integrated with systems such as SAP, Oracle, Microsoft, Kinaxis, or Aveva, can transform complex scheduling tasks into streamlined, data-driven processes.

By adopting a multi-objective approach, medical manufacturers can achieve the delicate balance between efficiency, compliance, and customer satisfaction, setting the stage for long-term success in an increasingly competitive industry.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.

Topics: PlanetTogether Software, Integrating PlanetTogether, Enhanced Data Visibility, Medical Manufacturing, Improved Collaboration

LEAVE A COMMENT