Multi-Channel Distribution

One of the most significant shifts in recent years has been the rise of multi-channel distribution in food and beverage manufacturing. From traditional retail to e-commerce platforms and everything in between, consumers now expect products to be available wherever and whenever they desire. While this presents exciting opportunities for reaching new markets and increasing revenue streams, it also brings forth unique challenges, particularly when it comes to production scheduling.

For plant managers in the food and beverage industry, effectively managing multi-channel distribution requires a delicate balance between meeting diverse customer demands, optimizing production efficiency, and ensuring seamless integration across various systems.

In this blog, we'll look into the impact of multi-channel distribution on scheduling and explore how integration between PlanetTogether and leading ERP, SCM, and MES systems can streamline operations and drive success.

Understanding Multi-Channel Distribution

Multi-channel distribution refers to the practice of selling products through multiple sales channels, such as brick-and-mortar stores, online platforms, wholesalers, distributors, and more. This approach offers numerous benefits, including expanded market reach, increased customer convenience, and enhanced flexibility. However, it also introduces complexities in inventory management, order fulfillment, and production scheduling.

In a multi-channel distribution environment, demand signals can vary significantly across channels. For example, while traditional retail outlets may experience relatively stable demand patterns, e-commerce channels often exhibit greater volatility and seasonality. Additionally, each sales channel may have its own unique requirements in terms of packaging, labeling, and delivery schedules, further complicating the production planning process.

Impact on Multi-channel Distribution on Scheduling

The impact of multi-channel distribution on scheduling cannot be overstated. Plant managers must contend with a multitude of factors, including fluctuating demand forecasts, shorter lead times, and increased SKU proliferation. Failure to effectively schedule production runs can result in inventory imbalances, stockouts, excess waste, and missed delivery deadlines, ultimately leading to dissatisfied customers and lost revenue.

Moreover, the complexity of multi-channel distribution can strain existing scheduling systems and processes. Traditional spreadsheet-based approaches often lack the agility and scalability required to adapt to rapidly changing market dynamics. Manual intervention becomes labor-intensive and error-prone, making it difficult to maintain optimal efficiency and responsiveness.

![]()

Integrating PlanetTogether with ERP, SCM, and MES Systems

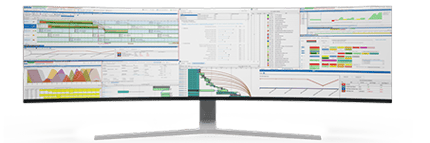

To address these challenges, forward-thinking plant managers are turning to advanced scheduling solutions that offer seamless integration with their existing ERP, SCM, and MES systems. One such solution is PlanetTogether, a leading provider of advanced production planning and scheduling software. By integrating PlanetTogether with ERP systems such as SAP, Oracle, Microsoft Dynamics, Kinaxis, Aveva, and others, plant managers can achieve greater visibility, agility, and control across the entire production ecosystem.

Integration between PlanetTogether and ERP systems enables real-time data synchronization, allowing plant managers to access accurate, up-to-date information on inventory levels, order volumes, and production capacities. This ensures that scheduling decisions are based on the latest insights, reducing the risk of overproduction or stockouts.

Furthermore, integration with SCM systems enables seamless communication with suppliers and logistics partners, facilitating just-in-time delivery of raw materials and finished goods. This minimizes lead times and inventory holding costs while maximizing supply chain efficiency and responsiveness.

MES integration allows for enhanced shop floor visibility and control, enabling plant managers to monitor production progress in real-time, identify bottlenecks, and adjust schedules accordingly. This fosters a more agile and adaptive manufacturing environment, capable of quickly responding to changing demand signals and market conditions.

Benefits of Integration

The benefits of integrating PlanetTogether with ERP, SCM, and MES systems are manifold. Firstly, it enables end-to-end visibility and traceability, allowing plant managers to track the entire production process from raw materials to finished products. This enhances quality control and regulatory compliance, reducing the risk of recalls and customer complaints.

Secondly, integration facilitates data-driven decision-making, leveraging advanced analytics and optimization algorithms to generate actionable insights. Plant managers can simulate various production scenarios, evaluate trade-offs, and identify the most cost-effective scheduling strategies. This enables them to maximize resource utilization, minimize production costs, and improve overall profitability.

Thirdly, integration enhances collaboration and coordination across functional departments, breaking down silos and fostering cross-functional alignment. By providing a centralized platform for sharing information and coordinating activities, it ensures that everyone is working towards common goals and objectives. This promotes a culture of continuous improvement and innovation, driving operational excellence and competitive advantage.

Optimizing Scheduling with PlanetTogether Integration

Let's consider a hypothetical example of a food and beverage manufacturing facility that produces a wide range of perishable goods for both retail and e-commerce channels. By integrating PlanetTogether with their existing ERP, SCM, and MES systems, the plant manager was able to achieve significant improvements in scheduling efficiency and effectiveness.

With real-time data synchronization between PlanetTogether and the ERP system, the plant manager gained greater visibility into inventory levels, order volumes, and production capacities. This enabled them to dynamically adjust production schedules in response to changing demand forecasts, minimizing stockouts and excess inventory.

Integration with the SCM system facilitated seamless communication with suppliers and logistics partners, enabling just-in-time delivery of raw materials and finished goods. This reduced lead times and transportation costs, while ensuring uninterrupted supply chain operations.

MES integration provided real-time visibility into production activities, allowing the plant manager to monitor progress, identify bottlenecks, and reoptimize schedules as needed. This improved throughput and on-time delivery performance, enhancing customer satisfaction and loyalty.

Overall, the integration of PlanetTogether with ERP, SCM, and MES systems enabled the plant manager to achieve greater agility, efficiency, and competitiveness in the face of multi-channel distribution challenges.

Multi-channel distribution presents both opportunities and challenges for food and beverage manufacturers. Effective scheduling is essential to success in this dynamic environment, requiring seamless integration between production planning software and ERP, SCM, and MES systems.

By integrating PlanetTogether with leading enterprise systems, plant managers can optimize scheduling processes, improve resource utilization, and enhance supply chain efficiency. This enables them to meet diverse customer demands, minimize costs, and drive sustainable growth in an increasingly competitive marketplace.

In the era of multi-channel distribution, the ability to adapt and innovate is essential for long-term success. With the right technology and strategic partnerships in place, plant managers can navigate the complexities of multi-channel distribution with confidence, positioning their organizations for continued success and growth.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.

Topics: PlanetTogether Software, Integrating PlanetTogether, Continuous Improvement, Maximize Resource Utilization, Food and Beverage Manufacturing, Enhances Quality Control and Regulatory Compliance, Enables End-to-End Visibility and Traceability, Facilitates Data-Driven Decision-Making, Enhances Collaboration and Coordination

LEAVE A COMMENT