Still Using Spreadsheets for Production Scheduling? Here’s Why That’s Holding You Back

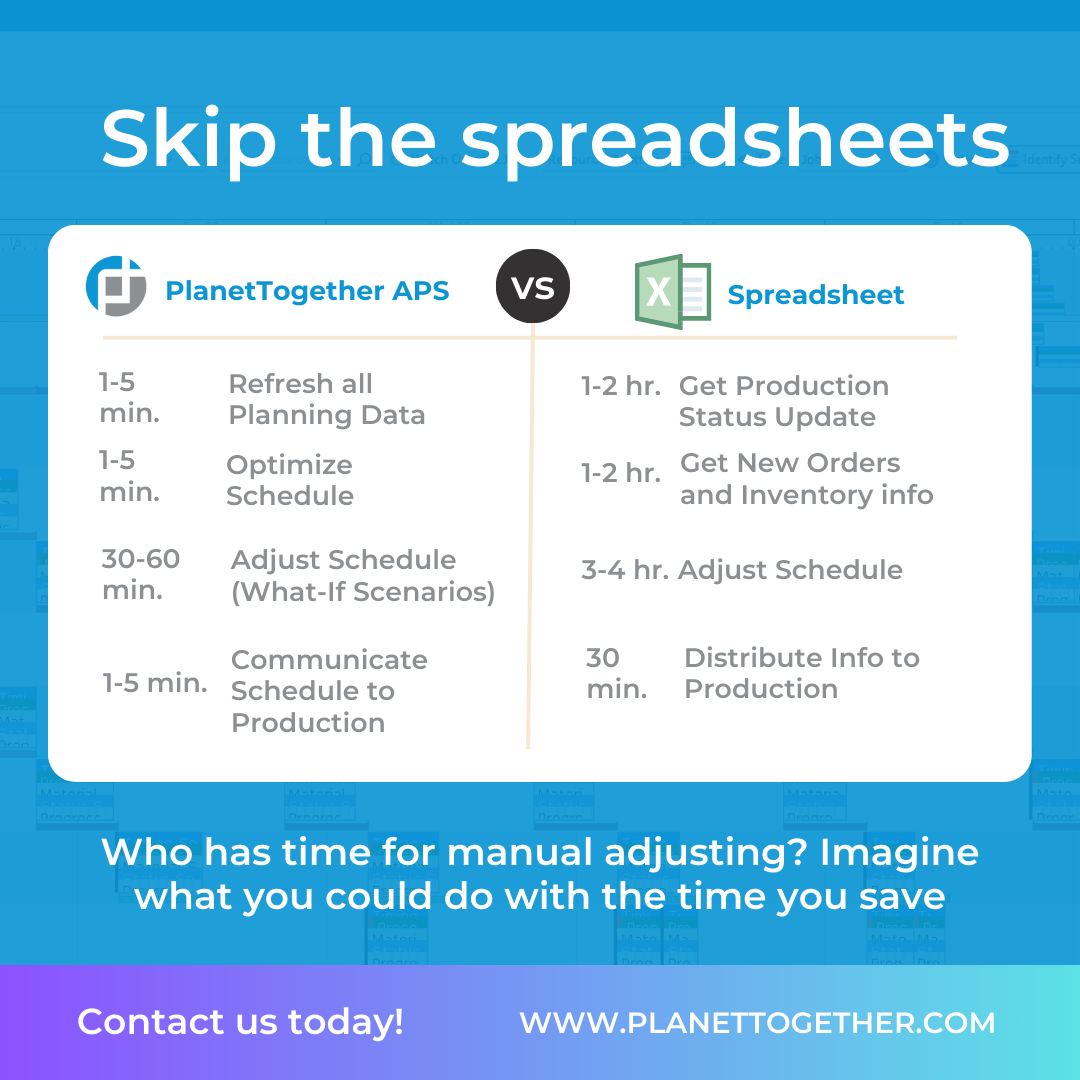

Spreadsheets like Excel are handy tools—easy to set up and familiar to most planners. But when it comes to manufacturing production scheduling, their simplicity becomes a limitation. They weren’t built to handle the dynamic, multi-layered needs of today’s operations.

If you’re constantly fighting to align production capacity, material availability, and last-minute order changes in a spreadsheet… you already know how fast things can spiral out of control.

Modern manufacturers need more than a static tool. They need a smarter, more responsive way to plan. That’s where advanced planning and scheduling software (APS) comes in.

What Makes Spreadsheets a Poor Fit for Production Scheduling?

-

Traditional planning systems often separate materials planning from capacity planning—and spreadsheets only add to that disconnect. This means:

-

No visibility into real-time constraints

-

Limited ability to respond to changes quickly

-

Manual data entry (and human error risks)

-

No way to optimize across KPIs like on-time delivery or machine utilization

As demand grows more volatile and lead times shrink, spreadsheets just can’t keep up.

-

What is Advanced Planning and Scheduling (APS) Software?

Advanced planning and scheduling software (APS) has become a must for modern-day manufacturing operations. APS can be quickly integrated with a ERP or MRP software, and fills in the gaps where these softwares lack.

Advanced planning and scheduling software (APS) offers various capabilities such as multi-plant operation integration, super-plant, real-time operational visibility, and overall throughput enhancement. Some of the other attributes of APS include the following:

- Improved Delivery Performance

- Profit Boost

- Reduction in Inventory and Cost

- Six-Month ROI

Top Features of Advanced Planning and Scheduling Software

Let’s take a look at the features that truly make a difference in a modern factory setting:

Real-Time Scheduling Visibility

Quickly assess how new jobs will impact capacity, delivery dates, and resource availability. This empowers planners to make faster, more informed decisions—keeping customer commitments on track.

Drag-and-Drop Gantt Scheduling

Visually schedule or reschedule orders with a user-friendly interface. Easily shift tasks while respecting constraints and delivery goals. No formulas. No guesswork.

Impact Analysis with One-Click Undo

Model schedule changes and immediately see how they affect orders and KPIs. Didn’t like the outcome? Revert with a click.

Custom Alerts for Teams

Get alerts when orders are late, machines are overloaded, or materials are delayed. Alerts are clickable, detailed, and customizable—keeping production, sales, and shipping in sync.

KPI-Based Optimization

Use your own weighted priorities—whether it’s throughput, changeovers, or delivery—to let the system auto-optimize your schedule. Focus on what matters most to your operation.

Flexible Real-Time Adjustments

Whether it’s an unexpected rush order or machine downtime, APS software helps you adjust schedules on the fly without breaking the flow of production.

Key Benefits of Switching from Excel to APS Software

Beyond features, the real value lies in what you gain long-term. Manufacturers who move to non-spreadsheet scheduling software often see results like:

- Improved On-Time Delivery

- Better Throughput and Capacity Utilization

- Lower Inventory and Operating Costs

- Return on Investment in Under Six Months

Plus, with integration into your existing ERP system, there’s no need to start from scratch.

Final Thoughts: Smarter Scheduling Starts with the Right Tools

If your production environment is struggling with manual planning, disconnected teams, or frequent disruptions, now’s the time to rethink your approach. Advanced planning and scheduling tools give manufacturers the ability to plan proactively, respond quickly, and operate more efficiently—without the limitations of spreadsheets.

You don’t need more data—you need better visibility, faster insights, and real-time control over your operations. Request a demo!

APS Resources

Topics: PlanetTogether, production planning and control, master production scheduling, production scheduling

LEAVE A COMMENT