The Impact of AI-Enabled Demand Forecasting Models in Pharmaceutical Manufacturing

Discover how AI-enabled demand forecasting transforms pharmaceutical manufacturing, optimizing production, reducing costs, and enhancing efficiency.

Discover how to modernize operations in chemical manufacturing with APS-ERP integration, boosting efficiency, compliance, and collaboration.

From regulatory requirements to customer demands for higher-quality products, the pressure is on production managers to deliver more efficient, reliable, and flexible operations. To stay competitive, modernizing operational models isn't just a choice—it's a necessity.

In this blog, we'll explore why modernizing your operation models is critical for success in chemical manufacturing, focusing on the integration of advanced planning and scheduling (APS) software like PlanetTogether with Enterprise Resource Planning (ERP) systems such as SAP, Oracle, Microsoft, Kinaxis, and Aveva. We'll cover the key benefits of digital transformation, explore how integrating these systems can streamline processes, and offer practical advice for getting started.

Chemical manufacturing is a complex, capital-intensive industry that deals with volatile raw materials, stringent regulations, and increasing pressure to innovate sustainably. Traditional models of production often rely on manual processes, legacy systems, and siloed departments. While these approaches may have worked in the past, they no longer suffice in the face of today’s challenges.

Some key issues that production managers must contend with include:

Inefficiencies in Scheduling and Resource Allocation: Without real-time data, production schedules can become misaligned, leading to overproduction, underutilization of equipment, or bottlenecks in the production line.

Increased Regulatory Scrutiny: With new regulations such as REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) in the EU and TSCA (Toxic Substances Control Act) in the U.S., chemical manufacturers need systems that can easily track compliance and audit trails.

Market Demands for Customization and Speed: Customers now expect shorter lead times and the ability to customize products, putting further strain on production schedules.

Sustainability and Environmental Regulations: Meeting environmental goals requires more efficient energy use and reduced waste, which in turn demands better visibility into every aspect of the production process.

![]()

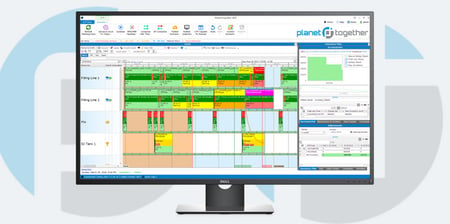

Advanced Planning and Scheduling (APS) software such as PlanetTogether is designed to tackle these challenges head-on. APS software provides the tools needed to optimize resource allocation, balance workloads, and adjust schedules dynamically based on real-time data. By doing so, it helps chemical manufacturers improve efficiency, reduce waste, and meet production targets more consistently.

Key features of APS software include:

Finite Capacity Scheduling: APS software considers the actual limitations of machines, labor, and raw materials, ensuring that your production schedule is realistic and achievable.

Real-time Data Integration: Modern APS systems gather data from sensors, machines, and operators, allowing you to make real-time adjustments to your schedule based on actual production progress.

Scenario Planning: APS allows production managers to run "what-if" scenarios, which helps in planning for unexpected disruptions like machine breakdowns or raw material shortages.

However, to fully realize the benefits of APS software, it must be integrated seamlessly with your broader ERP ecosystem, whether that's SAP, Oracle, Microsoft, Kinaxis, or Aveva. Let’s look at how integrating PlanetTogether with these ERP systems can further modernize your operation models.

For a production manager in a chemical manufacturing facility, the real power comes when you integrate your APS system with your existing ERP system. This is where the digital transformation of your operational models takes place. While an APS system like PlanetTogether excels in optimizing scheduling and resource allocation, ERP systems like SAP, Oracle, Microsoft Dynamics, Kinaxis, and Aveva handle the overall business management, including inventory control, procurement, and financials.

Without integration, production managers might find themselves bogged down by siloed information and data discrepancies. For example, your APS might show that a particular machine is available, but without real-time inventory data from your ERP, you might not know that the required raw materials are unavailable.

End-to-End Visibility: Integrating PlanetTogether with ERP systems like SAP or Oracle provides an end-to-end view of your operations. Whether it’s real-time inventory updates, production status, or machine availability, you get a single source of truth that enables better decision-making.

Enhanced Collaboration: Integration improves communication between departments, ensuring that production schedules align with procurement, inventory management, and order fulfillment. For example, an integrated system can alert your purchasing team to restock critical raw materials before they run out, preventing costly delays.

Improved Forecasting and Planning: With ERP integration, historical production data and business intelligence tools are easily accessible, enabling better forecasting and long-term production planning. Whether you’re using SAP’s predictive analytics or Oracle’s machine learning models, having both systems connected ensures you’re planning based on real-world data.

Regulatory Compliance: Compliance reporting becomes much easier when your APS and ERP systems are integrated. For instance, SAP and Aveva have built-in compliance tools that can automatically track and report on the production processes, while PlanetTogether helps ensure that your production schedules meet safety and environmental standards.

Cost Efficiency: Automation through integration reduces manual interventions, leading to cost savings in labor, energy, and material handling. The combined insights from both systems help you identify inefficiencies and optimize them, whether it’s reducing changeover times or minimizing waste.

SAP is one of the most widely used ERP systems in the chemical manufacturing industry, known for its robust modules in inventory management, financials, and procurement. Integrating PlanetTogether with SAP offers several advantages:

Real-Time Inventory Management: By integrating with SAP’s Material Management (MM) module, PlanetTogether can pull in real-time inventory data, ensuring that production schedules are based on the actual availability of raw materials.

Advanced Forecasting: With SAP’s powerful analytics engine, production managers can use historical data to forecast future demand and optimize production schedules accordingly. This is especially useful in industries like chemical manufacturing, where fluctuations in demand can lead to either excess inventory or stockouts.

Compliance and Reporting: Integration with SAP’s Environment, Health, and Safety (EHS) module ensures that chemical manufacturers remain compliant with regulations by automatically generating reports and tracking compliance metrics in real-time.

Oracle's ERP solutions offer deep functionality for financial management, procurement, and supply chain management. When integrated with PlanetTogether, Oracle can offer the following benefits:

Optimized Supply Chain Management: Oracle's Supply Chain Management (SCM) suite integrates seamlessly with PlanetTogether, ensuring that production schedules are fully aligned with supply chain activities, from raw material sourcing to final delivery.

Improved Financial Tracking: Oracle's financial modules can work with PlanetTogether to monitor the financial health of production activities in real-time, ensuring that you can adjust production schedules based on budget constraints or cost-saving opportunities.

Regulatory Compliance: Oracle's robust compliance features ensure that chemical manufacturers adhere to international standards. Combined with PlanetTogether's scheduling capabilities, you can easily track and document compliance throughout the production process.

Microsoft Dynamics is another popular ERP solution, known for its ease of use and integration with other Microsoft products. Here’s how integrating PlanetTogether with Microsoft Dynamics can modernize your operations:

Seamless Data Flow: Microsoft Dynamics integrates with a variety of data sources through its common data model, enabling PlanetTogether to easily pull in information from inventory, sales, and procurement systems.

Enhanced Collaboration: Integration with Microsoft’s suite of productivity tools like Teams and Outlook can streamline communication between departments, ensuring that everyone—from the production floor to the boardroom—has access to real-time data.

Scalable and Flexible: Microsoft Dynamics offers a highly scalable platform, meaning that as your operations grow, your integrated APS-ERP solution can scale with you, ensuring that you’re always optimizing production, no matter the size of your operation.

Kinaxis is known for its rapid planning and response capabilities, especially in complex supply chain environments. For chemical manufacturers, integrating PlanetTogether with Kinaxis offers several advantages:

Rapid Response to Disruptions: Kinaxis’ real-time monitoring and planning capabilities allow you to quickly adjust production schedules in PlanetTogether in response to supply chain disruptions, whether that’s a late shipment of raw materials or a sudden change in demand.

Risk Management: With Kinaxis' risk management tools, production managers can run simulations to see how different supply chain events could impact production, helping you proactively mitigate potential risks.

Synchronized Planning: By integrating Kinaxis' supply chain solutions with PlanetTogether's production scheduling, you ensure that production schedules remain in sync with broader supply chain activities, leading to more efficient operations.

Aveva’s digital solutions focus on industrial operations, offering tools that provide operational intelligence, asset performance management, and real-time data analytics. When integrated with PlanetTogether, Aveva can deliver several benefits:

Digital Twin Technology: Aveva’s digital twin capabilities allow chemical manufacturers to create a virtual model of their production processes, enabling better predictive maintenance and operational efficiency. Combined with PlanetTogether’s scheduling tools, you can optimize both machine performance and production schedules.

Operational Intelligence: Aveva’s real-time data analytics can provide valuable insights into plant performance, while PlanetTogether can adjust production schedules to address inefficiencies or take advantage of process improvements.

Sustainability Goals: Aveva’s focus on sustainability can be enhanced by integrating with PlanetTogether. Together, they can help you reduce waste, lower energy consumption, and meet sustainability targets by optimizing production processes.

Modernizing your operational models in chemical manufacturing is a multi-step process, but the benefits far outweigh the challenges involved. Here are some practical steps to help you begin integrating and modernizing your operation models.

Before implementing new technologies, it’s essential to understand where your current systems stand. Conduct an internal audit to evaluate the capabilities and limitations of your existing ERP, APS, and other legacy systems. Identify pain points in your production processes, such as bottlenecks, inefficiencies in scheduling, or issues with data integration across departments.

This stage will help you clearly define what problems you need to solve with the modernization effort. For example, if manual scheduling is causing delays and inefficiencies, you may prioritize integrating a system like PlanetTogether for better production planning.

Modernizing your operational models isn’t just about adopting new technologies—it’s about achieving specific, measurable outcomes. Set clear goals for what you want to accomplish. These could include:

Having clear objectives will also help you measure the success of your integration efforts and demonstrate return on investment (ROI) to stakeholders.

Once you’ve assessed your systems and set your goals, it’s time to choose the right tools for modernization. If you already have an ERP system like SAP, Oracle, Microsoft Dynamics, Kinaxis, or Aveva in place, your choice of APS software should focus on how well it integrates with your existing systems.

For example, if your goal is to improve scheduling, PlanetTogether offers seamless integration with many leading ERP systems, providing real-time production optimization. If sustainability is a priority, consider how Aveva’s operational intelligence can work with PlanetTogether to monitor and reduce your plant’s energy consumption.

One of the key benefits of modernizing your operations is the ability to break down silos and achieve end-to-end visibility across your production processes. To do this, you’ll need to focus on data integration. Whether you’re integrating PlanetTogether with SAP or Microsoft Dynamics, ensure that all relevant data—inventory levels, machine performance, raw material availability, etc.—is accessible and actionable in real-time.

This also means addressing data consistency and accuracy. Production managers in chemical manufacturing must ensure that data coming from various systems (APS, ERP, MES) is synchronized to avoid costly errors or misalignments.

Modernizing operational models is not just about installing new software—it's also about empowering your team to use it effectively. The best systems in the world won’t deliver results if your staff isn’t trained to use them properly. Training should be a continuous process that covers both the technical aspects of the software (such as using PlanetTogether for scheduling) and how to use the insights from integrated systems for better decision-making.

Invest in change management programs that ensure your staff is ready and willing to embrace the new technology. This is particularly important in chemical manufacturing, where workers may be used to manual processes or legacy systems. Clear communication about the benefits of modernization—faster production times, fewer errors, better compliance—can help gain employee buy-in.

Rather than implementing a full-scale integration immediately, start with a pilot program to test how the integration between your APS (PlanetTogether) and ERP (SAP, Oracle, etc.) works in practice. Choose a single production line or a smaller segment of your facility to run the integration and work out any issues before rolling it out plant-wide.

This pilot phase will give you a clearer picture of the potential challenges, such as data discrepancies or training gaps, and allow you to refine your approach before committing to a full-scale transformation.

Once your systems are integrated and running, continuous monitoring is key. This is where PlanetTogether’s real-time capabilities come in handy. Production managers can track the performance of their operations in real-time, ensuring that schedules are followed, resources are optimized, and output is meeting expectations.

You can also use the data gathered through your APS-ERP integration to run optimization exercises. For example, analyze downtime patterns to improve preventive maintenance schedules, or look at production data to identify where resources are being over- or under-utilized.

As you gather more data and insights, you can scale the integration to cover more areas of your facility, and potentially introduce additional technology solutions that complement your modernization efforts, such as Internet of Things (IoT) devices for real-time machine monitoring or artificial intelligence for predictive analytics.

While the benefits of modernizing operational models in chemical manufacturing are clear, there are also challenges to be mindful of. Here are some common obstacles and how to overcome them:

Resistance to Change: Employees and even management may resist modernization efforts, especially if they’re used to legacy systems or manual processes. Address this through clear communication of the benefits and robust change management programs.

Data Silos: Integrating APS and ERP systems requires breaking down departmental silos and ensuring that data flows freely across the organization. This may require cultural as well as technological changes.

Initial Costs: The upfront investment for modernization—including new software, integration, and training—can be significant. However, focusing on long-term gains like increased efficiency, reduced waste, and improved compliance can help justify the initial costs to stakeholders.

Compliance and Security: Ensuring that your modernized systems meet industry regulations and data security standards is critical in chemical manufacturing. Partner with trusted software providers (such as SAP or Aveva) that offer built-in compliance and security features.

Modernizing your operational models is just the beginning. As we move deeper into the era of Industry 4.0, chemical manufacturing is likely to become even more automated, data-driven, and connected. Technologies like artificial intelligence (AI), machine learning, IoT, and blockchain will play increasingly important roles in optimizing production processes, managing supply chains, and ensuring regulatory compliance.

By integrating APS systems like PlanetTogether with ERP platforms such as SAP, Oracle, Microsoft, Kinaxis, or Aveva, you are laying the foundation for this future. These integrations allow you to collect, analyze, and act on vast amounts of data, driving continuous improvement in your operations.

The next step will be to further enhance these systems with predictive analytics, AI-driven decision-making, and IoT connectivity. Imagine a future where your machines can predict their own failures, your supply chain adjusts itself in real-time to market conditions, and your production lines are fully optimized without any human intervention.

This vision of the future is not as far away as it might seem. By taking steps to modernize your operation models today, you’ll be better prepared to embrace these technologies when they become more widely available and affordable.

For production managers in chemical manufacturing facilities, modernizing operational models is no longer optional—it’s essential. By integrating advanced planning and scheduling systems like PlanetTogether with ERP systems such as SAP, Oracle, Microsoft Dynamics, Kinaxis, or Aveva, you can optimize production, enhance compliance, improve collaboration, and achieve greater operational efficiency.

The path to modernization involves assessing your current systems, setting clear goals, integrating data across departments, and training your team to make the most of new tools. Start with a pilot program, monitor performance, and continuously optimize your processes as you scale the integration plant-wide.

Ultimately, modernization sets the stage for embracing Industry 4.0, positioning your facility for success in a rapidly evolving industry. With the right tools, processes, and mindset, chemical manufacturers can not only meet today’s challenges but thrive in tomorrow’s industry landscape.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.

Discover how AI-enabled demand forecasting transforms pharmaceutical manufacturing, optimizing production, reducing costs, and enhancing efficiency.

Revolutionize pharmaceutical manufacturing with cloud computing: Boost efficiency, compliance, and scalability in MOM. #PharmaCloud

Explore risk management and quality assurance strategies for chemical production planners, integrating PlanetTogether with ERP systems for seamless,...

Be the first to know about new B2B SaaS Marketing insights to build or refine your marketing function with the tools and knowledge of today’s industry.