Maximizing Efficiency with Flexible Manufacturing Systems

The demand for flexibility in manufacturing systems has never been greater in the industrial landscape. Customers expect customization, quick turnaround times, and flawless execution, all while keeping costs competitive. As a production scheduler, you're at the forefront of this transformation, tasked with orchestrating complex operations to meet these demands seamlessly.

In this blog, we look into the concept of Flexible Manufacturing Systems (FMS) and explore how integrating advanced planning and scheduling tools like PlanetTogether with ERP, SCM, and MES systems can revolutionize your approach to production scheduling, driving efficiency, agility, and ultimately, competitive advantage.

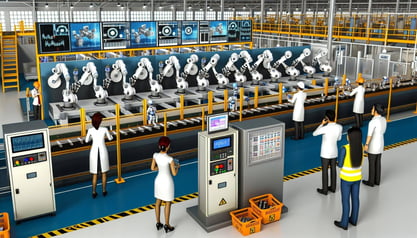

Flexible Manufacturing Systems (FMS)

Flexible Manufacturing Systems represent a paradigm shift in manufacturing philosophy. Traditionally, production lines were static, designed to churn out large volumes of standardized products efficiently. However, with changing market dynamics and customer preferences, manufacturers are increasingly adopting FMS to cope with variability, uncertainty, and the need for customization.

At its core, FMS enables agile and adaptive manufacturing processes that can swiftly respond to changes in demand, product specifications, and resource availability. Key characteristics of FMS include:

Modularity and Scalability: FMS consists of modular production units that can be easily reconfigured or expanded to accommodate different products or production volumes.

Interoperability: FMS components seamlessly communicate with each other and with external systems, enabling real-time data exchange and coordination.

Adaptive Control: FMS leverages advanced control algorithms and predictive analytics to optimize production in response to dynamic conditions.

Resource Flexibility: FMS allows for the efficient utilization of resources, including machinery, labor, and materials, by dynamically allocating them based on current needs and constraints.

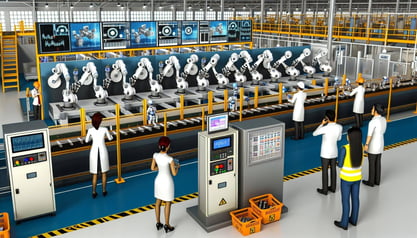

The Role of Production Scheduler in FMS

As a Production Scheduler operating within an FMS environment, your responsibilities extend beyond traditional scheduling tasks. You're not just coordinating production orders and resources; you're orchestrating a complex ecosystem of interconnected processes, balancing conflicting objectives such as minimizing lead times, maximizing resource utilization, and ensuring on-time delivery.

Your role encompasses:

Strategic Planning: Collaborating with stakeholders to define production goals, capacity constraints, and resource allocation strategies aligned with business objectives.

Tactical Scheduling: Generating feasible production schedules that optimize resource utilization, minimize idle time, and meet customer demand within constraints.

Real-time Monitoring and Adaptation: Continuously monitoring production progress, identifying bottlenecks or deviations from the plan, and making real-time adjustments to ensure smooth operations.

Integration and Collaboration: Facilitating seamless integration between planning, scheduling, and execution systems, and fostering collaboration across departments to streamline workflows and improve responsiveness.

Leveraging Advanced Planning and Scheduling Tools

To effectively fulfill your role in an FMS environment, you need robust tools that can handle the complexity and variability inherent in modern manufacturing operations. This is where advanced planning and scheduling (APS) software like PlanetTogether comes into play.

PlanetTogether offers a comprehensive suite of features designed to empower production schedulers with the tools they need to thrive in a dynamic manufacturing environment. Some key functionalities include:

Scenario Analysis: Evaluate multiple production scenarios to identify the most optimal schedule based on different criteria such as resource availability, order priorities, and lead times.

Constraint-based Scheduling: Take into account various constraints such as machine capacity, material availability, and labor skills when generating schedules, ensuring feasibility and adherence to operational constraints.

Real-time Visualization: Gain real-time visibility into production schedules, resource utilization, and order statuses through intuitive dashboards and interactive Gantt charts, enabling proactive decision-making and quick response to disruptions.

Integration Capabilities: Seamlessly integrate with leading ERP, SCM, and MES systems such as SAP, Oracle, Microsoft, Kinaxis, and Aveva, ensuring data consistency and enabling end-to-end visibility across the supply chain.

Integration: The Key to Seamless Operations

Integration between PlanetTogether and ERP, SCM, and MES systems is the linchpin of effective production scheduling in an FMS environment. By synchronizing data and processes across disparate systems, integration enables:

Unified Data Management: Eliminate silos and discrepancies by ensuring that all systems have access to accurate, up-to-date information regarding orders, inventory levels, production capacities, and more.

Streamlined Workflows: Automate data exchange and workflow orchestration between planning, scheduling, and execution systems, reducing manual effort and minimizing errors.

Enhanced Decision Support: Leverage consolidated data from across the enterprise to gain insights into production performance, identify trends, and make informed decisions to optimize operations.

Agile Response to Changes: Enable real-time communication and collaboration between stakeholders, allowing for swift adjustments to production schedules in response to changing demand, supply disruptions, or resource constraints.

As a Production Scheduler navigating the era of Flexible Manufacturing Systems, you play a pivotal role in driving operational excellence and maintaining a competitive edge in today's dynamic marketplace. By leveraging advanced planning and scheduling tools like PlanetTogether and integrating them with ERP, SCM, and MES systems, you can streamline production operations, enhance agility, and deliver superior value to your organization and its customers.

Embrace the opportunities presented by FMS, harness the power of integration, and embark on a journey towards optimized, resilient, and future-ready manufacturing operations. The future of production scheduling is flexible, and it's within your grasp to shape it.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.

LEAVE A COMMENT