Dynamic Pricing Strategies and Scheduling

Plant managers constantly grapple with the challenge of optimizing production schedules to meet demand while minimizing costs. However, in today's fast-paced market, traditional static pricing strategies and rigid scheduling methods may not cut it anymore. That's where dynamic pricing strategies and scheduling come into play, offering innovative solutions to enhance productivity and profitability.

In this blog, we'll look into the significance of dynamic pricing strategies and scheduling in food and beverage manufacturing. Furthermore, we'll explore how integration between advanced planning and scheduling (APS) software like PlanetTogether and enterprise resource planning (ERP), supply chain management (SCM), and manufacturing execution systems (MES) such as SAP, Oracle, Microsoft, Kinaxis, and Aveva can revolutionize operations.

Dynamic Pricing Strategies

Dynamic pricing, also known as surge pricing or demand pricing, is a strategy where prices fluctuate based on market demand, time of day, competitor pricing, and other variables. While it's commonly associated with industries like hospitality and transportation, it's increasingly gaining traction in food and beverage manufacturing.

The food and beverage industry experiences fluctuating demand due to various factors such as seasonality, consumer preferences, and even weather conditions. Dynamic pricing enables manufacturers to adjust prices in real-time to capitalize on high demand periods while remaining competitive during lulls.

Benefits of Dynamic Pricing in Food and Beverage Manufacturing

Maximizing Revenue: By aligning prices with demand, manufacturers can maximize revenue potential, especially during peak periods. For example, during holidays or special events, dynamically adjusting prices can help capture additional profits without compromising customer loyalty.

Managing Inventory: Dynamic pricing strategies can influence consumer behavior, encouraging purchases during off-peak hours or for products nearing expiration. This helps in reducing inventory holding costs and minimizing waste.

Competitive Advantage: In a crowded market, offering dynamic pricing can differentiate a brand from competitors. It demonstrates responsiveness to market dynamics and enhances the overall customer experience.

Challenges of Implementing Dynamic Pricing

While dynamic pricing offers numerous benefits, its implementation in food and beverage manufacturing isn't without challenges. Some of the key hurdles include:

Data Complexity: Dynamic pricing relies heavily on real-time data analysis, including sales trends, competitor pricing, and market conditions. Managing and interpreting this data accurately can be daunting without robust analytical tools.

Pricing Strategy Alignment: Dynamic pricing strategies must align with broader business objectives and brand positioning. Striking the right balance between profitability and customer perception requires careful consideration.

Operational Integration: Implementing dynamic pricing seamlessly requires integration between pricing software, ERP systems, and production processes. Lack of integration can lead to inefficiencies and inaccuracies.

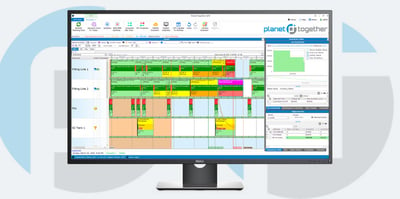

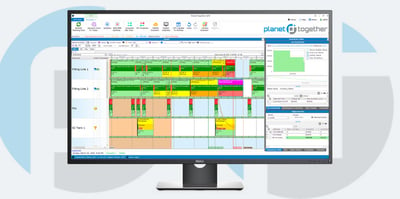

Integrating Dynamic Pricing with Advanced Planning and Scheduling (APS) Software

Here's where advanced planning and scheduling (APS) software like PlanetTogether comes into play. APS solutions enable plant managers to optimize production schedules based on real-time demand signals, inventory levels, and resource availability. When integrated with ERP, SCM, and MES systems, APS software enhances visibility and coordination across the entire manufacturing ecosystem.

Benefits of Integrating APS with ERP, SCM, and MES Systems

Real-time Decision Making: Integration between APS and ERP systems provides plant managers with real-time insights into demand fluctuations, enabling proactive decision-making. This ensures production schedules are aligned with dynamic pricing strategies to maximize profitability.

Seamless Coordination: By connecting APS with SCM and MES systems, manufacturers can streamline communication and coordination between production, procurement, and distribution processes. This minimizes bottlenecks and enhances overall efficiency.

Enhanced Forecasting Accuracy: APS software utilizes advanced algorithms and predictive analytics to forecast demand more accurately. When integrated with ERP systems, this ensures pricing decisions are based on reliable data, reducing the risk of overstocking or stockouts.

Dynamic pricing strategies and scheduling are essential tools for food and beverage manufacturers looking to stay competitive in today's market. By leveraging advanced planning and scheduling (APS) software like PlanetTogether and integrating it with ERP, SCM, and MES systems, plant managers can optimize production processes, maximize revenue, and enhance customer satisfaction.

In an increasingly dynamic business environment, the ability to adapt quickly to changing market conditions is essential. By embracing innovation and investing in technology-enabled solutions, food and beverage manufacturers can position themselves for long-term success. Dynamic pricing and scheduling aren't just buzzwords—they're the keys to unlocking operational excellence and driving sustainable growth.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.

LEAVE A COMMENT