Here are the steps involved in grouping jobs by material attributes. In this case, jobs will be grouped based on their material thickness attribute.

The intent is to reduce setup time associated with reconfiguring the resource to handle different material thicknesses.

For this example, I will optimize the grouping of jobs using material in the material grouping called "Fin Stock". Any jobs in the "Fin Stock" material grouping will be grouped by the material's part number. The "Fin Stock" material group includes parts that have a thickness associated with their processing by a Fin Press resource. If material isn't in the "Fin Stock" group, then we won't want the optimizer to worry about it.

Material Grouping will not be the only optimization rule in effect, so we will also see how the relative weights of each of the rules will affect the outcome of the job grouping after optimization.

Material Grouping is a standard feature in PlanetTogether APS and is covered elsewhere. For this example, assume that the material groupings are already in effect.

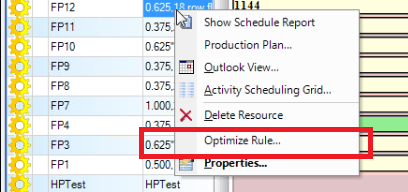

Now, to optimize the FP12 (Fin Press) resource:

1) Right-Click the resource and choose "Optimize Rule...":

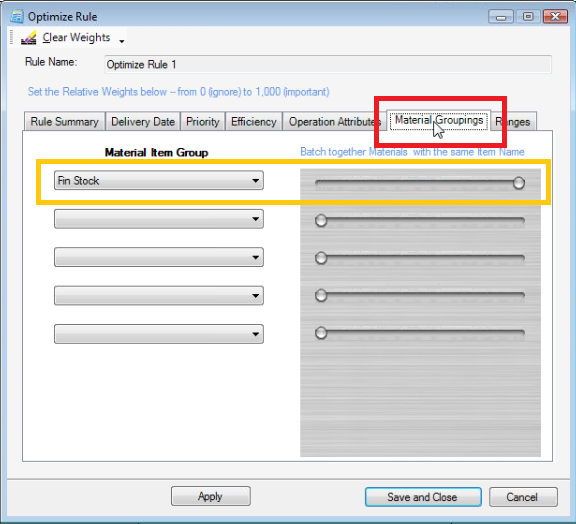

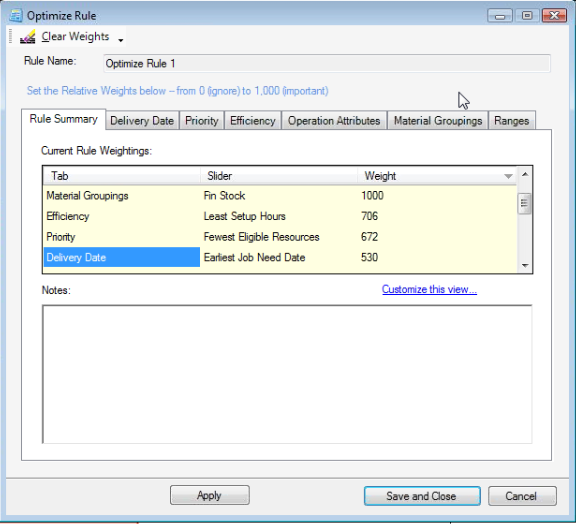

2) Select the Material Groupings tab in the Optimize Rule pop-up window. In this example, the Material Group called "Fin Stock" is given a maximum weighting. Other material groupings can be chosen from the subsequent drop-down menus:

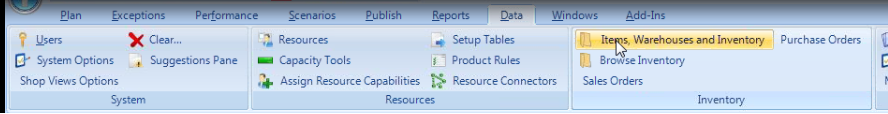

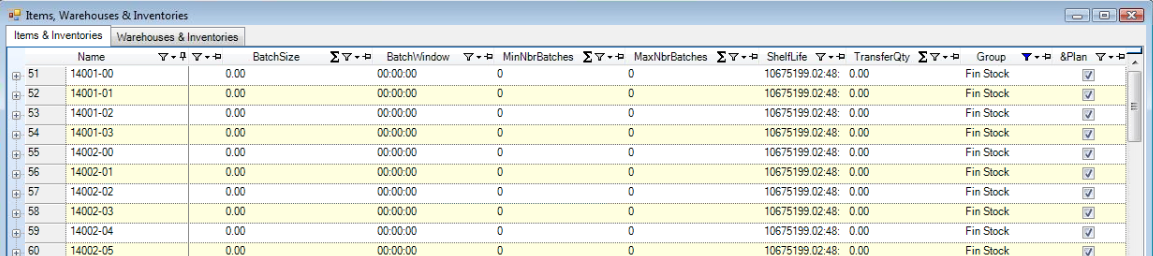

3) To see an item's material grouping, select "Items, Warehouses and Inventory" from the Data tab:

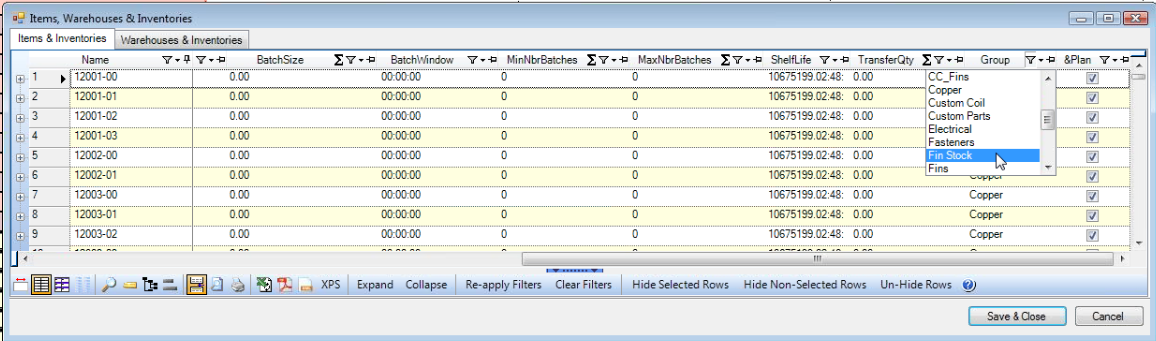

4) We can select specific material grouping categories from the drop-down menu of the Group field. In this example, "Fin Stock" is chosen:

5) Items in the Fin Stock group are shown:

6) Now we will look at the rules in the Optimize Rule pop-up window, and see the relative weights of the existing rules:

Note: This information can be misleading. The Fin Stock Material Groupings rule has a weight of 1000, and the Least Setup Hours Efficiency rule has a weight of 706, but that 706 value is multiplied by the number of Setup Hours. So, if a job would have 2 hours of setup, then the 2 is multiplied by the 706 to get a weight of 1412, which is higher that the Fin Stock weight of 1000, and therefore the job that would incur 2 hours of setup has precedence. To avoid confusion, these "weights" should be normalized.

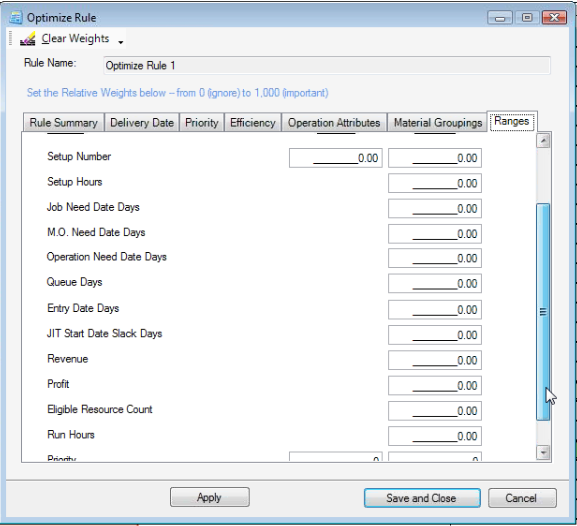

7) The Ranges tab of the Optimize Rule pop-up window allows you to normalize the weight values:

In the case of "Setup Hours", pick a maximum value for the setup hours field. Let us say that the most setup hours for any fin press is 4 hours, then the weight applies to the range of setup from 0 to 4 hours. In other words, the job that had a setup time of 2 hours is thought to be 50% of the range from 0 to 4. This 50% is multiplied by the rule's wight of 706, giving a value of 343. So the job with setup hours of 2 yields a setup hours optimization rule value of 353, which is compared to the job whose material grouping optimization rules value is 1000. The jobs with the same material will take precedence over jobs with 2 hours of setup.

Related Materials Planning Video

APS Resources