Topics: PlanetTogether Software, Integrating PlanetTogether, Streamlined Operations, Efficient Order Fulfillment, Enhanced Visibility, Improved Collaboration Across Teams, Dynamic Scenario Analysis, Packaging Manufacturing, Batch Processes

In the world of manufacturing, where efficiency and precision reign supreme, production schedulers serve as the linchpin in ensuring smooth operations. In batch processing industries, such as packaging manufacturing, the role of a scheduler becomes even more critical. The complexity of managing multiple products, varying batch sizes, and intricate production sequences demands a sophisticated scheduling approach.

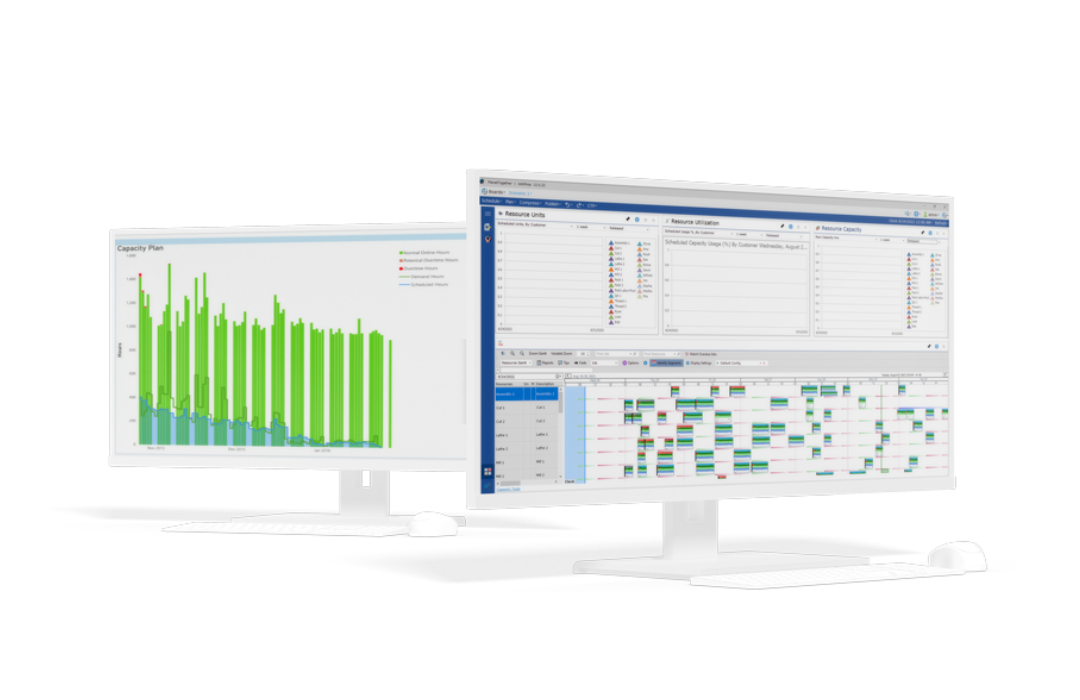

In this guide, we'll look into the nuances of scheduling in batch processes and explore how the integration of advanced scheduling tools like PlanetTogether with ERP, SCM, and MES systems can revolutionize your operations.

Unlike continuous manufacturing, where products flow continuously through the production line, batch processes involve the production of finite quantities of a product in distinct batches. This approach offers flexibility, allowing manufacturers to produce different products with minimal changeover time.

However, this flexibility comes with its challenges. Batch processes require meticulous planning to optimize resource utilization, minimize downtime, and meet customer demands. This is where an efficient scheduling system becomes indispensable.

Production schedulers in batch processing industries face a myriad of challenges:

Batch Sequencing: Determining the optimal sequence in which batches should be processed to minimize changeover times and maximize throughput.

Resource Allocation: Allocating resources such as equipment, labor, and raw materials efficiently to meet production targets while minimizing costs.

Minimizing Idle Time: Avoiding idle time between batches by synchronizing production schedules with material availability and equipment readiness.

Meeting Deadlines: Ensuring timely delivery of products while accommodating rush orders and unexpected disruptions.

Traditional scheduling methods, relying on manual spreadsheets or rudimentary software, fall short in addressing the complexities of batch processes. This is where advanced scheduling solutions like PlanetTogether come into play.

PlanetTogether offers a comprehensive suite of features tailored to the needs of batch manufacturing:

Dynamic Scheduling: PlanetTogether's algorithmic approach dynamically adjusts schedules in response to real-time changes, ensuring optimal utilization of resources and minimizing idle time.

Scenario Analysis: Production schedulers can simulate various production scenarios to evaluate the impact of schedule changes on key performance indicators such as throughput, lead times, and resource utilization.

Integration Capabilities: One of the standout features of PlanetTogether is its seamless integration with leading ERP, SCM, and MES systems. Whether you're using SAP, Oracle, Microsoft Dynamics, Kinaxis, Aveva, or any other system, PlanetTogether ensures data consistency across the entire manufacturing ecosystem.

Advanced Analytics: PlanetTogether provides actionable insights through advanced analytics, enabling production schedulers to identify bottlenecks, anticipate resource constraints, and optimize production schedules proactively.

The integration between PlanetTogether and ERP, SCM, and MES systems is a game-changer for production schedulers. By leveraging real-time data exchange and synchronization, this integration enables:

Streamlined Operations: Seamless data flow between scheduling and enterprise systems eliminates manual data entry, reduces errors, and ensures alignment between production plans and business objectives.

Enhanced Visibility: Production schedulers gain real-time visibility into inventory levels, order statuses, and production progress across the supply chain, enabling better decision-making and faster response to changing market dynamics.

Improved Collaboration: Integration fosters collaboration between departments by providing stakeholders with access to timely and accurate information, facilitating cross-functional communication and alignment.

Efficient Order Fulfillment: With integrated scheduling, production, and inventory management, manufacturers can fulfill customer orders more efficiently, reducing lead times and enhancing customer satisfaction.

To harness the full potential of advanced scheduling tools and integration capabilities, production schedulers should adopt the following best practices:

Data Accuracy: Ensure data accuracy and integrity across all systems to avoid discrepancies that could lead to scheduling errors and production delays.

Continuous Optimization: Continuously review and optimize production schedules based on changing demand patterns, resource constraints, and market dynamics.

Collaborative Planning: Foster collaboration between production, procurement, and sales teams to align production schedules with demand forecasts and customer requirements.

Invest in Training: Provide training and support to production schedulers to maximize their proficiency in using scheduling tools and interpreting analytics insights.

In the world of batch manufacturing, mastering scheduling is the key to staying competitive and responsive to market demands. By leveraging advanced scheduling tools like PlanetTogether and integrating them with ERP, SCM, and MES systems, production schedulers can optimize resource utilization, minimize downtime, and deliver superior customer value.

Embrace the power of scheduling excellence and propel your packaging manufacturing facility towards operational excellence.

Topics: PlanetTogether Software, Integrating PlanetTogether, Streamlined Operations, Efficient Order Fulfillment, Enhanced Visibility, Improved Collaboration Across Teams, Dynamic Scenario Analysis, Packaging Manufacturing, Batch Processes

0 Comments

No video selected

Select a video type in the sidebar.

LEAVE A COMMENT