Mastering Demand Forecasting and Inventory Management in Chemical Manufacturing: The Strategic Role of PlanetTogether Integration

In chemical manufacturing, where fluctuations in demand, lead times, and raw material availability can cause significant disruptions, the role of the Production Planner is more critical than ever. Navigating this complexity requires a blend of accurate demand forecasting and efficient inventory management—two capabilities that, when executed correctly, drive responsiveness, reduce costs, and improve service levels.

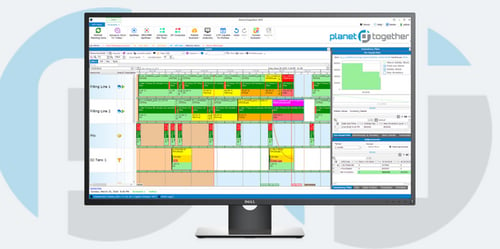

To achieve this, chemical manufacturers are increasingly relying on advanced planning and scheduling (APS) tools like PlanetTogether, especially when integrated with enterprise systems such as SAP, Oracle, Microsoft Dynamics, Kinaxis, or Aveva. This integration forms the backbone of a responsive, data-driven supply chain that empowers Production Planners to make smarter, faster decisions.

The Complexity of Chemical Manufacturing

Chemical manufacturing involves numerous challenges that distinguish it from other industrial sectors:

Volatile raw material prices

Strict regulatory requirements

Shelf-life limitations

Hazardous material handling

Complex bill of materials and batch processing

Given this landscape, accurate demand forecasting and inventory optimization aren't optional—they're survival mechanisms. Misjudging demand can lead to costly overproduction or dangerous stockouts, both of which can have regulatory and financial consequences.

The Interdependency Between Demand Forecasting and Inventory Management

At its core, demand forecasting is about predicting customer requirements over a defined period. Inventory management, on the other hand, focuses on ensuring that the right products are available at the right time without overstocking or understocking.

In chemical manufacturing, these two functions are deeply intertwined. For instance:

A spike in demand for a chemical compound requires upstream planning for raw material procurement.

Inaccurate forecasts can lead to expired inventory or regulatory violations from improper storage.

Inventory buffers must be optimized to prevent both production stoppages and excessive working capital.

Production Planners serve as the bridge, translating demand signals into actionable production schedules, procurement plans, and resource allocations.

Leveraging PlanetTogether APS for Greater Precision

PlanetTogether Advanced Planning and Scheduling (APS) is a powerful solution built to help planners model, visualize, and optimize complex manufacturing operations. It offers real-time scheduling, scenario planning, constraint-based optimization, and what-if simulations. When integrated with platforms like SAP, Oracle, Microsoft, Kinaxis, or Aveva, it enables holistic demand-driven manufacturing.

Key Capabilities Beneficial for Demand Forecasting and Inventory Management:

Real-Time Visibility

Integration with SAP or Oracle enables PlanetTogether to ingest sales orders, forecasts, and inventory levels.

This real-time sync allows planners to monitor fluctuations and adjust plans accordingly.

Constraint-Based Scheduling

Automatically adjusts production schedules based on material availability, equipment capacity, labor, and shift patterns.

Avoids overproduction or bottlenecks resulting from unrealistic plans.

Scenario Planning and Simulations

PlanetTogether allows you to run multiple “what-if” scenarios to test the impact of changes in demand or supply.

Helps planners identify optimal strategies to buffer risks.

Dynamic Safety Stock Adjustments

Integration with demand forecasting models from systems like Kinaxis enables PlanetTogether to adjust inventory targets dynamically.

Enhances service levels while minimizing excess inventory.

KPI-Driven Dashboards

Integrations with Microsoft Dynamics or Aveva enable custom visual dashboards.

Planners can track forecast accuracy, inventory turns, on-time delivery, and stockout rates in real-time.

Benefits of Integration with ERP and SCM Systems

The full potential of demand forecasting and inventory management is only realized when APS tools like PlanetTogether are deeply integrated with ERP and supply chain platforms.

SAP and Oracle:

Enable end-to-end material traceability.

Provide master data, historical sales, and real-time procurement status.

Feed back production schedules into financial and order management modules for closed-loop planning.

Microsoft Dynamics:

Delivers flexibility in configuring workflows tailored for mid-sized chemical manufacturers.

Enhances data flow between finance, procurement, and production.

Kinaxis:

Supports advanced demand sensing, enabling production planners to adjust schedules based on market trends and short-term variability.

Offers deep analytics for strategic inventory placement.

Aveva:

Facilitates real-time asset performance monitoring, ensuring that forecasted production doesn’t exceed available equipment capability.

Enables predictive maintenance data to be factored into production schedules.

Best Practices for Production Planners

To get the most out of demand forecasting and inventory management, Production Planners in chemical manufacturing should consider the following best practices:

Integrate Early and Deeply

Prioritize seamless integration between PlanetTogether and your ERP/SCM platform. Real-time data is key to responsiveness.

Collaborate Across Departments

Work closely with procurement, sales, and quality control to ensure forecast assumptions are well-informed.

Incorporate External Data

Factor in market trends, seasonality, and even weather data when developing demand forecasts.

Model Multiple Scenarios

Use PlanetTogether’s what-if capabilities to simulate the impact of demand surges, supplier delays, or equipment breakdowns.

Continuously Improve

Track KPIs like forecast accuracy, inventory turnover, and service levels. Use these insights to refine your planning approach.

Demand forecasting and inventory management are the pillars of operational efficiency in chemical manufacturing. With growing pressure to reduce waste, meet regulatory standards, and stay responsive to market shifts, the role of the Production Planner has never been more strategic.

Tools like PlanetTogether—especially when integrated with robust systems like SAP, Oracle, Microsoft, Kinaxis, or Aveva—transform the planning process from reactive to proactive. They empower planners with the insight, agility, and control needed to drive performance, reduce costs, and ensure customer satisfaction in an increasingly dynamic manufacturing environment.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.

Topics: Real-time Visibility, PlanetTogether Software, Constraint-Based Scheduling, Integrating PlanetTogether, Chemical Manufacturing, Scenario Planning and Simulations, Dynamic Safety Stock Adjustments, KPI-Driven Dashboards

LEAVE A COMMENT