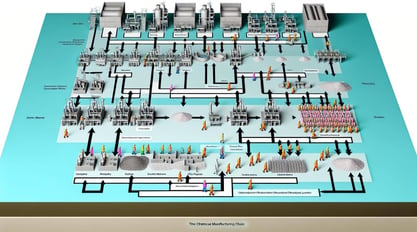

Manufacturing Supply Chain Mapping

The intricate dance of the supply chain can make or break operational efficiency, cost-effectiveness, and ultimately, success in chemical manufacturing. As a Supply Chain Manager, you're tasked not only with overseeing this dance but also with orchestrating it to perfection. Enter the concept of Manufacturing Supply Chain Mapping, a powerful tool that enables you to visualize, analyze, and optimize every step of the production journey.

In this blog, we'll look into the significance of Supply Chain Mapping specifically tailored to chemical manufacturing facilities. Moreover, we'll explore the integration possibilities between PlanetTogether—a leading supply chain planning software—and prominent ERP, SCM, and MES systems like SAP, Oracle, Microsoft, Kinaxis, and Aveva, to streamline operations and enhance efficiency.

Understanding the Complexity

Chemical manufacturing supply chains are inherently complex, characterized by a multitude of raw materials, intricate processes, stringent regulations, and diverse distribution channels. Navigating this complexity requires a deep understanding of each component's interplay and its implications on the overall efficiency and profitability.

Supply Chain Mapping offers a comprehensive view of the entire manufacturing ecosystem, from raw material sourcing to final product delivery. It allows Supply Chain Managers to identify bottlenecks, anticipate potential disruptions, and optimize resource allocation at every stage of the production cycle.

The Role of PlanetTogether

At the heart of effective supply chain mapping lies robust planning and scheduling software. PlanetTogether stands out as a leader in this domain, offering advanced features tailored to the unique needs of chemical manufacturing facilities.

By leveraging PlanetTogether, Supply Chain Managers can create detailed production plans that align with demand forecasts, resource constraints, and operational priorities. This enables proactive decision-making, minimizing the impact of unforeseen events and maximizing resource utilization.

Integration with ERP, SCM, and MES Systems

While PlanetTogether provides unparalleled capabilities in production planning and scheduling, its integration with ERP, SCM, and MES systems enhances its effectiveness even further. Let's explore how this integration can revolutionize supply chain management in chemical manufacturing facilities:

SAP Integration

Seamless synchronization of production plans with SAP's robust ERP system.

Real-time visibility into inventory levels, procurement status, and financial data.

Enhanced accuracy in demand forecasting and inventory optimization.

Oracle Integration

Integration with Oracle's SCM solutions enables end-to-end supply chain visibility.

Streamlined communication between production planning and procurement processes.

Improved collaboration with suppliers and distributors through Oracle's network.

Microsoft Integration

Integration with Microsoft Dynamics ERP enhances data interoperability and workflow automation.

Unified platform for financial management, inventory tracking, and production planning.

Access to advanced analytics and business intelligence tools for informed decision-making.

Kinaxis Integration

Seamless data exchange between PlanetTogether and Kinaxis RapidResponse for supply chain optimization.

Enhanced agility in response to demand fluctuations and supply disruptions.

Comprehensive scenario analysis capabilities for risk management and contingency planning.

Aveva Integration

Integration with Aveva's MES solutions ensures real-time monitoring of production processes.

Improved production visibility, quality control, and compliance management.

Enhanced coordination between planning, execution, and monitoring activities.

The integration between PlanetTogether and these ERP, SCM, and MES systems creates a cohesive ecosystem where data flows seamlessly across different functional areas. This integration eliminates silos, reduces manual intervention, and accelerates decision-making, ultimately driving operational excellence across the entire supply chain.

Benefits of Supply Chain Mapping

Now, let's explore the tangible benefits that Supply Chain Mapping, powered by PlanetTogether and integrated ERP, SCM, and MES systems, brings to chemical manufacturing facilities:

Enhanced Operational Efficiency

Streamlined production planning and scheduling minimize idle time and maximize resource utilization.

Real-time visibility into inventory levels and production status enables proactive decision-making.

Optimized allocation of resources reduces lead times and improves on-time delivery performance.

Improved Cost Management

Accurate demand forecasting and inventory optimization minimize excess inventory and stockouts.

Integration with ERP systems enables cost tracking and variance analysis across the entire supply chain.

Efficient use of resources and reduced waste contribute to overall cost savings.

Increased Agility and Resilience

Scenario analysis and "what-if" simulations enable Supply Chain Managers to anticipate and mitigate risks.

Rapid response to demand fluctuations and supply disruptions ensures business continuity and customer satisfaction.

Flexibility in production planning allows for quick adaptation to changing market conditions and regulatory requirements.

Enhanced Collaboration and Visibility

Integration with ERP, SCM, and MES systems facilitates seamless communication and data exchange across departments.

Stakeholders have access to real-time information, fostering collaboration and alignment towards common goals.

Comprehensive reporting and analytics tools provide insights for continuous improvement and strategic decision-making.

In chemical manufacturing, Supply Chain Mapping powered by advanced planning and scheduling software like PlanetTogether, integrated with leading ERP, SCM, and MES systems, is no longer a luxury but a necessity. It equips Supply Chain Managers with the tools and insights needed to navigate the complexities of the supply chain landscape, optimize operations, and drive sustainable growth.

By embracing Supply Chain Mapping and leveraging the power of integration, chemical manufacturing facilities can achieve unprecedented levels of operational efficiency, cost-effectiveness, and resilience in an ever-evolving market environment. The journey towards excellence begins with a clear understanding of the supply chain maze and the right tools to navigate it effectively.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.

Topics: PlanetTogether Software, Integrating PlanetTogether, Enhanced Operational Efficiency, Enhanced Collaboration and Visibility, Chemical Manufacturing, Improved Cost Management, Increased Agility and Resilience, Manufacturing Supply Chain Mapping

LEAVE A COMMENT