Managing Supply Chain Disruptions with PlanetTogether and ERP Integration in Industrial Manufacturing

Supply chain disruptions have become a persistent challenge for industrial manufacturing facilities. From raw material shortages and transportation delays to labor constraints and regulatory changes, production planners must navigate an increasingly complex landscape. The ability to respond swiftly and effectively to these disruptions is crucial to maintaining operational efficiency, meeting customer demands, and ensuring profitability.

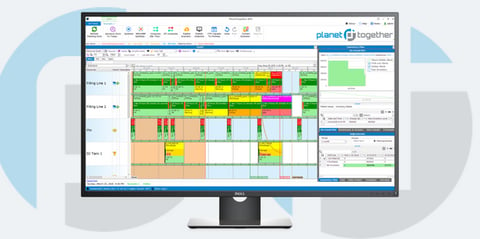

A key enabler of effective disruption management is the integration of Advanced Planning and Scheduling (APS) solutions like PlanetTogether with Enterprise Resource Planning (ERP) systems such as SAP, Oracle, Microsoft, Kinaxis, and Aveva. This integration allows production planners to gain real-time visibility, optimize scheduling dynamically, and make data-driven decisions to mitigate supply chain risks.

Understanding Supply Chain Disruptions in Industrial Manufacturing

Industrial manufacturing operations rely on a complex network of suppliers, production lines, and distribution channels. Any disruption in the supply chain can lead to:

Increased lead times affecting production schedules.

Material shortages resulting in bottlenecks.

Inefficient resource utilization, leading to waste and higher costs.

Customer dissatisfaction due to delayed deliveries.

Traditional planning methods struggle to adapt to real-time disruptions, making it necessary to leverage digital tools that offer agility, visibility, and automation.

The Role of PlanetTogether APS in Disruption Management

PlanetTogether APS provides real-time scheduling and optimization capabilities that empower production planners to quickly adapt to disruptions. When integrated with ERP systems, it enhances decision-making by synchronizing supply chain data across all levels of manufacturing.

Some key benefits include:

Dynamic Scheduling Adjustments: Real-time re-scheduling based on updated material availability and workforce constraints.

Scenario Planning: Simulating disruption scenarios to evaluate mitigation strategies before execution.

Bottleneck Identification: Early detection of constraints, allowing proactive resolution.

Improved Visibility: Holistic insights into demand, inventory, and capacity constraints.

Integration of PlanetTogether APS with ERP Systems

SAP + PlanetTogether: Predictive Planning for Resilient Operations

SAP ERP provides extensive data on procurement, production, and distribution. When integrated with PlanetTogether, manufacturers can:

Predict potential disruptions using AI-driven analytics.

Align production schedules with real-time inventory levels.

Improve cross-functional collaboration by ensuring supply chain teams have synchronized data.

Oracle + PlanetTogether: Supply Chain Synchronization

Oracle ERP's robust supply chain management tools, when integrated with PlanetTogether, enable:

Automated order prioritization based on real-time material availability.

Rapid adjustment of work orders to accommodate supply chain disruptions.

Integrated analytics dashboards for proactive decision-making.

Microsoft Dynamics + PlanetTogether: Enhanced Supply Chain Agility

For manufacturers using Microsoft Dynamics, integration with PlanetTogether provides:

Cloud-based synchronization of production and supply chain data.

Automated alerts and notifications for proactive issue resolution.

Enhanced collaboration tools for cross-departmental coordination.

Kinaxis + PlanetTogether: End-to-End Demand and Supply Alignment

Kinaxis offers rapid supply chain planning capabilities. When combined with PlanetTogether, manufacturers benefit from:

Concurrent planning that aligns demand fluctuations with production capacity.

Faster response times to supply chain changes.

Automated risk mitigation strategies based on predictive analytics.

Aveva + PlanetTogether: Leveraging Industrial IoT for Real-time Adjustments

Aveva’s industrial software solutions, when integrated with PlanetTogether, facilitate:

IoT-driven production insights for predictive maintenance and scheduling.

Real-time energy and resource optimization for sustainability goals.

Improved plant-floor synchronization by aligning digital twin technology with production planning.

Strategies for Managing Supply Chain Disruptions Using APS & ERP Integration

To maximize the benefits of integrating APS with ERP systems, production planners should implement the following strategies:

Develop Contingency Plans: Utilize scenario modeling in PlanetTogether to prepare for potential supply chain disruptions. Having predefined action plans ensures a swift response to unexpected events.

Enhance Supplier Collaboration: Leverage ERP integration to maintain real-time communication with suppliers, ensuring visibility into material availability and lead times.

Monitor Key Performance Indicators (KPIs): Track critical KPIs such as on-time delivery, production cycle times, and resource utilization to continuously improve supply chain resilience.

Automate Decision-making: Implement AI-driven analytics and automation tools to adjust production schedules dynamically, minimizing manual intervention.

Optimize Inventory Management: Maintain an optimal balance of raw materials and finished goods using real-time data from ERP and APS systems.

Leverage Predictive Analytics: Use machine learning capabilities to identify trends and potential risks before they escalate into disruptions.

The integration of PlanetTogether APS with ERP systems like SAP, Oracle, Microsoft, Kinaxis, and Aveva is a game-changer for managing supply chain disruptions in industrial manufacturing. By enabling real-time visibility, predictive analytics, and dynamic scheduling, production planners can navigate disruptions efficiently, ensuring sustained operational excellence and customer satisfaction.

Investing in APS-ERP integration is no longer a luxury but a operational imperative in today’s volatile manufacturing environment. Embracing this digital transformation will empower production planners to proactively manage uncertainties, optimize resource allocation, and enhance overall supply chain resilience.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.

Topics: Industrial Manufacturing, PlanetTogether Software, Integrating PlanetTogether, Improved Visibility, Dynamic Scheduling Adjustments., Scenario Planning, Proactive Bottleneck Identification

LEAVE A COMMENT