Topics: Centralized Data Management, PlanetTogether Software, Integrating PlanetTogether, Dynamic Scheduling, Enhanced Collaboration, Optimize Resource Utilization, Pharmaceutical Manufacturing, Advanced Scenario Planning, Improve Agility

Regulatory changes, raw material shortages, unexpected equipment downtime, and fluctuating customer demands all require manufacturers to respond rapidly. For Operations Directors, the challenge is to manage these disruptions efficiently while maintaining compliance, ensuring quality, and meeting delivery timelines.

Artificial Intelligence (AI), combined with advanced production planning tools like PlanetTogether, offers a powerful solution. When integrated with enterprise resource planning (ERP) systems such as SAP, Oracle, Microsoft Dynamics, Kinaxis, or Aveva, these technologies enable real-time visibility, enhanced decision-making, and proactive response mechanisms.

Let’s explore how AI-driven solutions and integrated platforms empower pharmaceutical manufacturers to handle last-minute changes effectively.

Pharmaceutical manufacturing operates under stringent regulations and requires precision at every stage of production. Last-minute changes, such as sudden demand shifts or regulatory updates, can cascade through the supply chain, impacting everything from procurement to final delivery. Without the right tools, addressing these changes often results in inefficiencies, increased costs, and higher risks of non-compliance.

For Operations Directors, the stakes are particularly high. They must ensure that:

Production schedules remain feasible.

Resources are allocated optimally.

Regulatory standards are upheld.

Costs and waste are minimized.

This is where AI and advanced scheduling tools like PlanetTogether shine.

AI algorithms are transforming how pharmaceutical manufacturers approach production planning. Predictive analytics powered by AI can anticipate potential disruptions by analyzing historical data, market trends, and real-time inputs. When paired with PlanetTogether, AI capabilities extend to:

Dynamic Scheduling: AI algorithms adjust production schedules in real-time to accommodate last-minute changes. For example, if a critical raw material delivery is delayed, AI can automatically reschedule production tasks while minimizing downtime.

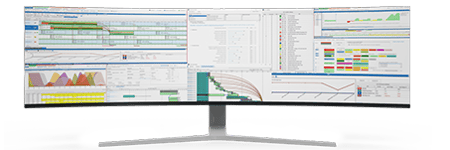

Scenario Planning: PlanetTogether’s integration with tools like SAP and Oracle enables Operations Directors to simulate various scenarios, such as regulatory changes or demand spikes. AI evaluates these scenarios, offering optimized solutions that align with operational goals.

Demand Forecasting: AI-driven demand forecasting helps manufacturers anticipate shifts in market needs. By integrating this capability with PlanetTogether, planners can proactively adjust production schedules and resource allocation.

![]()

Seamless integration between PlanetTogether and ERP systems like SAP, Oracle, Microsoft Dynamics, Kinaxis, or Aveva is a game-changer for pharmaceutical manufacturing. These integrations enable real-time data flow, ensuring that all stakeholders have access to the latest information. Here’s how this integration benefits Operations Directors:

Centralized Data: ERP systems serve as a single source of truth, consolidating data from procurement, production, and distribution. PlanetTogether leverages this data to optimize scheduling and resource allocation.

Enhanced Collaboration: Integration fosters cross-departmental collaboration. For example, purchasing managers can align raw material orders with updated production schedules, reducing delays.

Regulatory Compliance: Integrated systems ensure traceability and documentation, critical for meeting regulatory requirements. AI-powered solutions can flag compliance risks early, allowing for timely corrective actions.

Imagine a scenario where a new regulatory requirement mandates a formulation change for a popular pharmaceutical product. This last-minute change necessitates immediate adjustments across the production line.

Detection: AI systems integrated with PlanetTogether and ERP tools identify the impact of the regulatory change, from raw material sourcing to production timelines.

Simulation: PlanetTogether runs various scheduling scenarios to determine the most efficient way to implement the change without disrupting other production lines.

Execution: Once the optimal plan is identified, PlanetTogether updates schedules in real-time, while the ERP system ensures that procurement and inventory align with the new requirements.

Monitoring: AI monitors production progress, flagging any deviations and suggesting corrective actions to keep the project on track.

By leveraging AI and integrating PlanetTogether with leading ERP systems, Operations Directors can:

Improve Agility: Respond to disruptions quickly without compromising production efficiency or quality.

Optimize Resources: Maximize the utilization of equipment, labor, and materials, even during unforeseen changes.

Ensure Compliance: Maintain strict adherence to regulatory requirements, minimizing risks of non-compliance.

Reduce Costs: Avoid costly delays, rework, and waste by making data-driven decisions.

Enhance Visibility: Gain real-time insights into operations, enabling proactive management and better decision-making.

Managing last-minute changes in pharmaceutical manufacturing is no small feat. However, with AI and advanced tools like PlanetTogether integrated with ERP systems such as SAP, Oracle, Microsoft Dynamics, Kinaxis, or Aveva, Operations Directors have the tools they need to maintain efficiency, compliance, and quality. The future of pharmaceutical manufacturing lies in harnessing the power of technology to drive smarter, faster, and more agile operations.

To stay competitive, it’s essential to invest in digital transformation strategies that prioritize real-time visibility, advanced analytics, and seamless integration. The combination of AI and PlanetTogether provides the agility and intelligence needed to turn last-minute changes from a challenge into an opportunity.

Are you ready to take your manufacturing operations to the next level? Contact us today to learn more about how PlanetTogether can help you achieve your goals and drive success in your industry.

Topics: Centralized Data Management, PlanetTogether Software, Integrating PlanetTogether, Dynamic Scheduling, Enhanced Collaboration, Optimize Resource Utilization, Pharmaceutical Manufacturing, Advanced Scenario Planning, Improve Agility

0 Comments

LEAVE A COMMENT